Piezoelectric conductor ceramic clamping fixture

A technology for clamping fixtures and conductors, applied in workpiece clamping devices, manufacturing tools, etc., to solve problems such as shaking, unstable clamping of piezoelectric conductor ceramics, and small contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] For example figure 1 -example Figure 5 Shown:

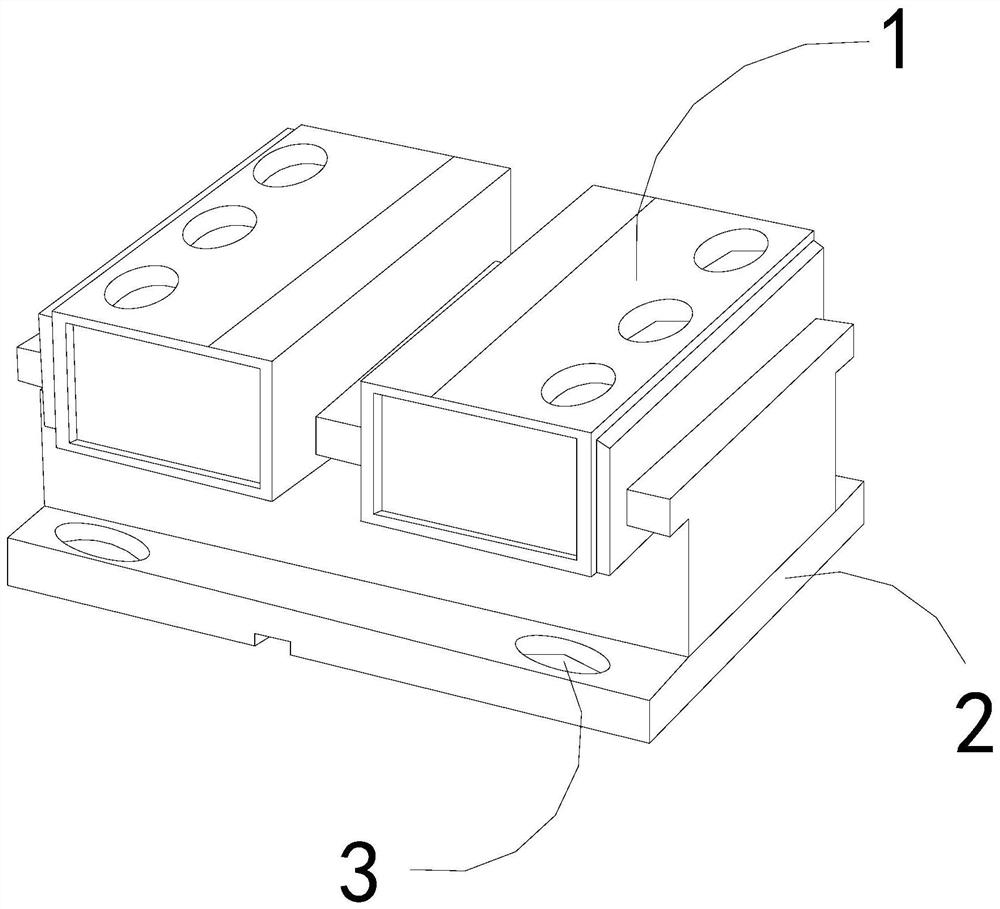

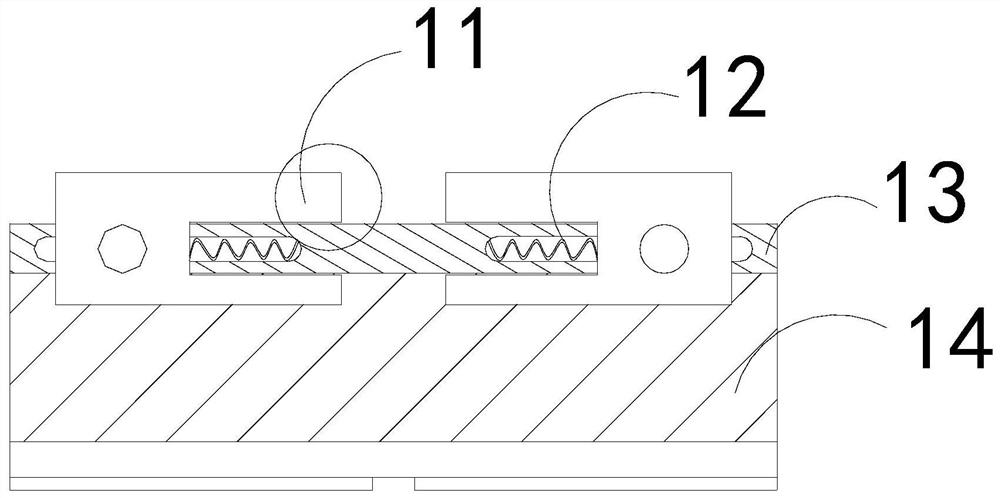

[0027] The present invention provides a clamping fixture for piezoelectric conductor ceramics, the structure of which includes a fixing mechanism 1, a bottom plate 2, and a connecting hole 3, the connecting hole 3 and the bottom plate 2 are an integrated structure, and the fixing mechanism 1 is embedded in the bottom plate 2 The upper end position; the fixing mechanism 1 includes a clamping plate 11, a power strip 12, a guide plate 13, and a bottom plate 14, the clamping plate 11 is movably engaged with the guide plate 13, and the power strip 12 is installed on the guide plate 13 and the bottom plate 14. Between the clamping plates 11, the guide plate 13 and the bottom plate 14 are an integrated structure.

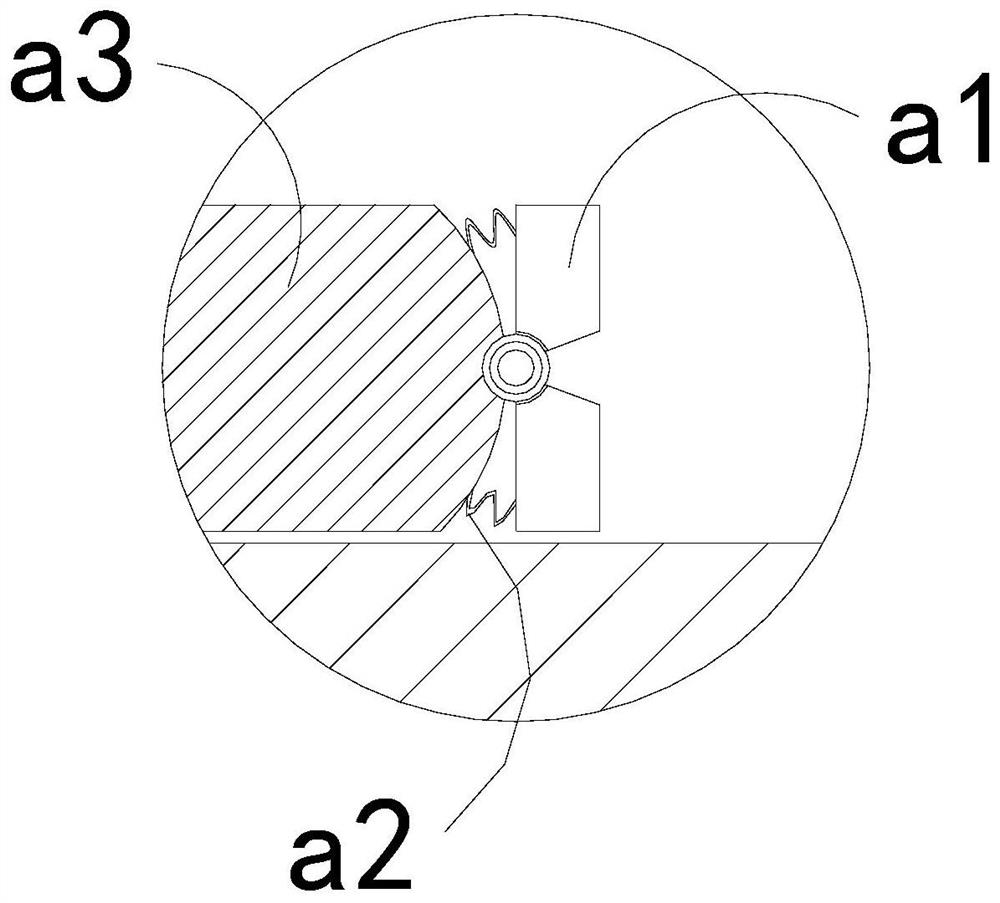

[0028] Wherein, the clamping plate 11 includes a front plate a1, a connecting bar a2, and a bottoming plate a3, the front plate a1 is hinged to the right side of the bottoming plate a3, and the connecting bar a2 is ...

Embodiment 2

[0034] For example Figure 6 -example Figure 8 Shown:

[0035] Wherein, the grip groove b2 includes a stabilizing bar b21, an inner connecting plate b22, a bearing plate b23, and a deformation block b24. The stabilizing bar b21 is embedded in the right side of the inner connecting plate b22, and the inner connecting plate b22 The deformed block b24 is connected to the bearing plate b23, and the deformed block b24 is made of polyether sponge material with high density, and the deformed block b24 can be reset by the deformed block b24.

[0036] Wherein, the stabilizing bar b21 includes an outer push piece c1, a combination block c2, and an outer expansion plate c3, and the outer push piece c1 is installed between two outer expansion plates c3, and the outer expansion plate c3 and the combination block c2 are movable There are two outer expansion plates c3, which are evenly distributed symmetrically at the upper and lower ends of the joint block c2, and the outer expansion pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com