Special socket for tap

A sleeve and tap technology, applied in the field of drilling tools, can solve problems such as low efficiency, inconvenient production site application, and many parts, so as to ensure processing efficiency and processing accuracy, improve equipment utilization, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

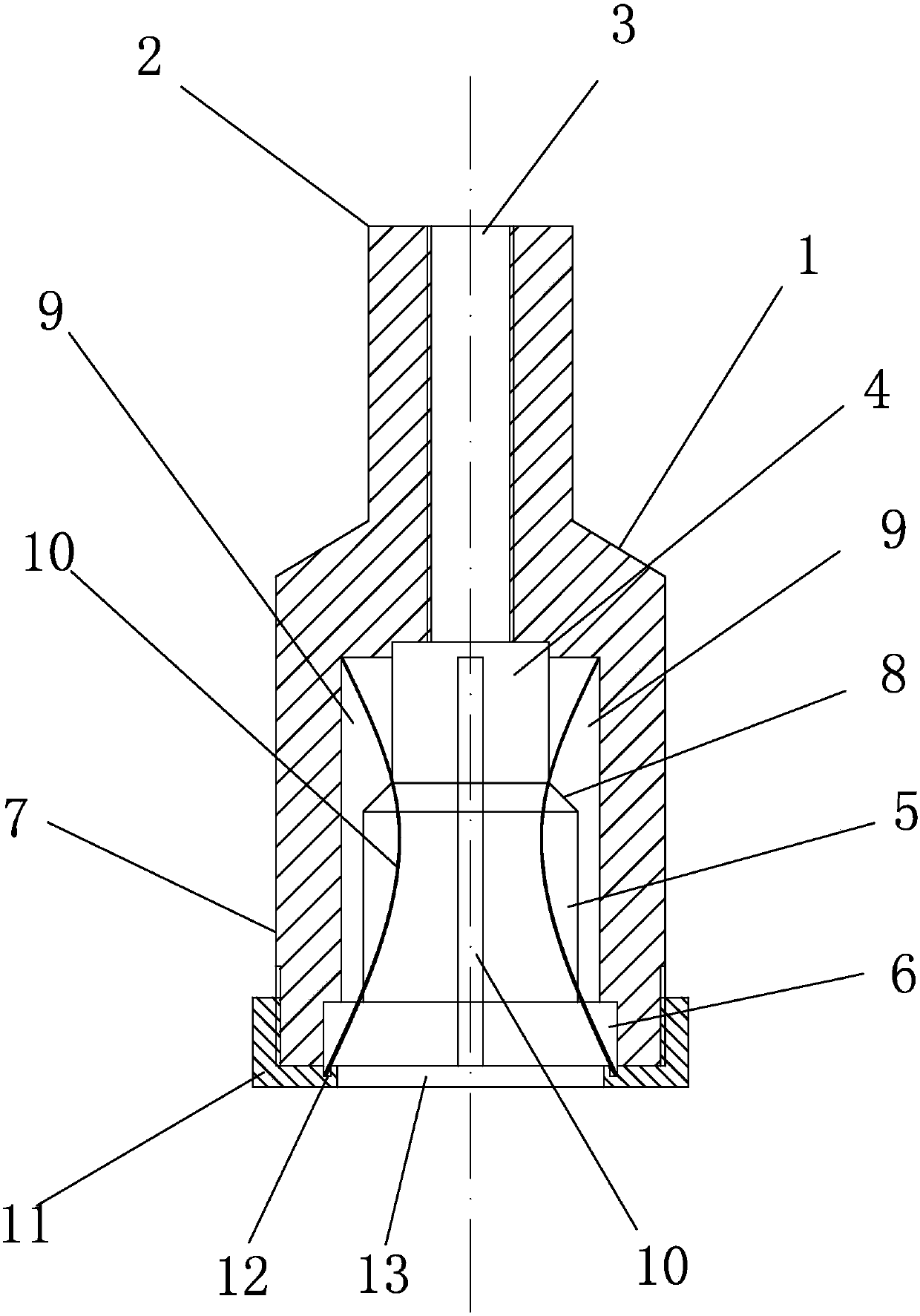

[0014] Embodiment: the screw tap special sleeve of the present invention, as attached figure 1 As shown, it includes a rod-shaped body 1, one end of the rod-shaped body 1 is a fixed end 2, and the other end is a clamping end 7, and the fixed end 2 is a regular hexagon 2 adapted to the fixing structure of the tapping device; the clamping end 7 The end face is provided with a mounting hole; the mounting hole is a stepped hole, including the first fixing hole 5 and the second fixing hole 4, the first fixing hole 5 and the second fixing hole 4 are square holes adapted to the tail end of the tap, along the The rod-shaped body 1 is arranged on an axis. The end face of the clamping end 7 is provided with a circular counterbore 6, and the middle part of the bottom of the circular counterbore 6 is provided with a first fixing hole 5. A transition portion 8 is provided between the first fixing hole 5 and the second fixing hole 4, and the transition portion 8 is a tapered surface.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com