Method for producing warp knitting coral velvet polyester filament yarn

A technology of polyester filament and production method, which is applied in textiles and papermaking, and can solve the problems of easy falling or sticking wool, insufficient softness of coral fleece fabric, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with specific embodiment, further set forth the present invention, it is necessary to point out that the following examples are only used to further illustrate the present invention, can not be interpreted as the restriction to protection scope of the present invention, those skilled in the art can make according to the content of above-mentioned invention Make some non-essential adjustments. These equivalent forms also fall within the scope defined by the appended claims of this application.

[0013] A kind of technical process for warp knitting coral fleece polyester filament of the present invention:

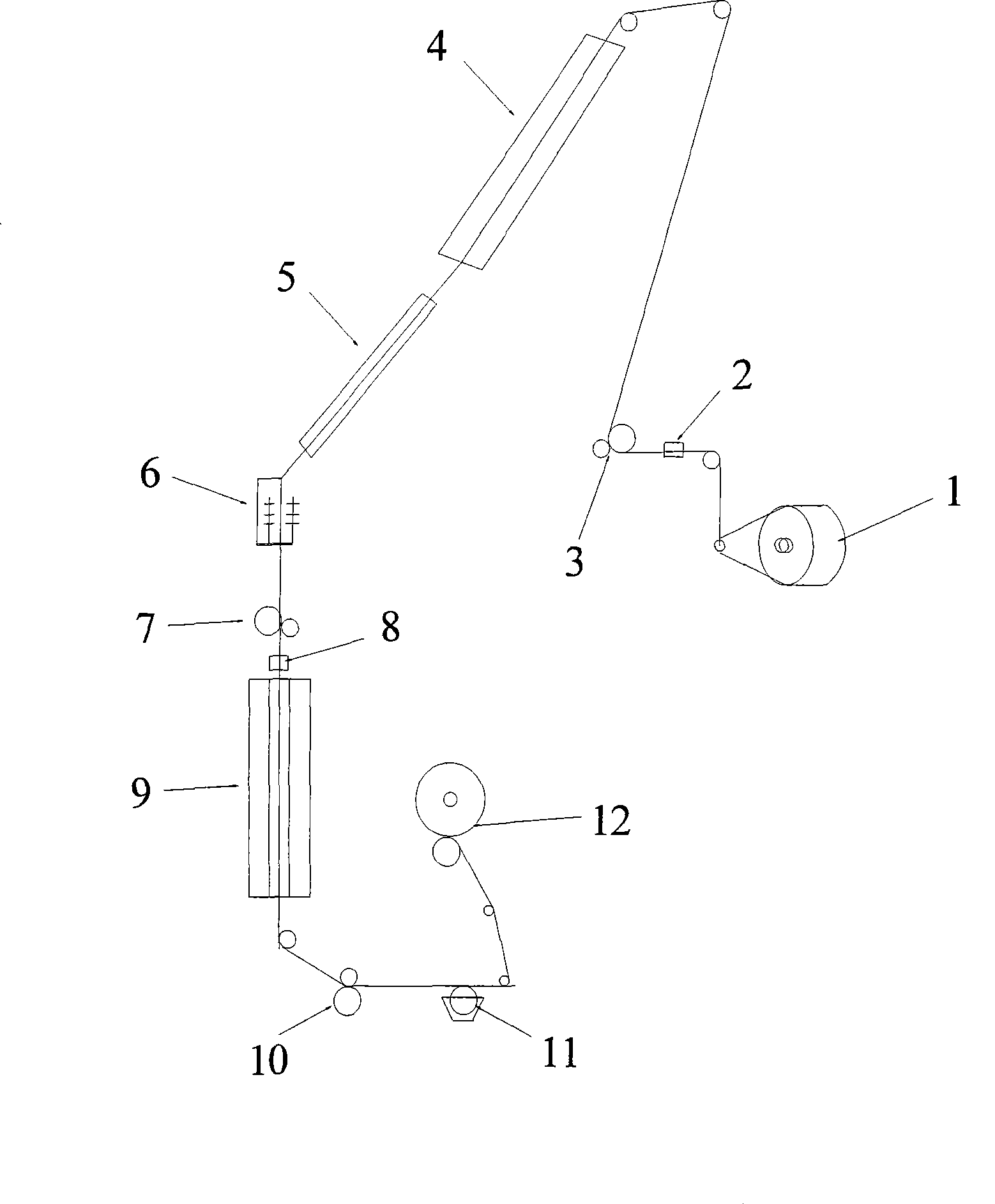

[0014] POY raw yarn→feeding by one roller→heating and deformation by one hot box→cooling→false twisting→feeding by two rollers→heating and shaping by two hot boxes→feeding by three rollers→oiling→DTY winding forming, POY raw yarn and one roller A pre-network process is added between feeding.

[0015] Such as figure 1 As shown, the polyester pre-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com