High temp. hot case of false twist texturing machine

A false-twist texturing machine and warm technology, applied in textiles and papermaking, can solve the problems of reduced safety factor, slow temperature rise of biphenyl, large volume of hot box, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

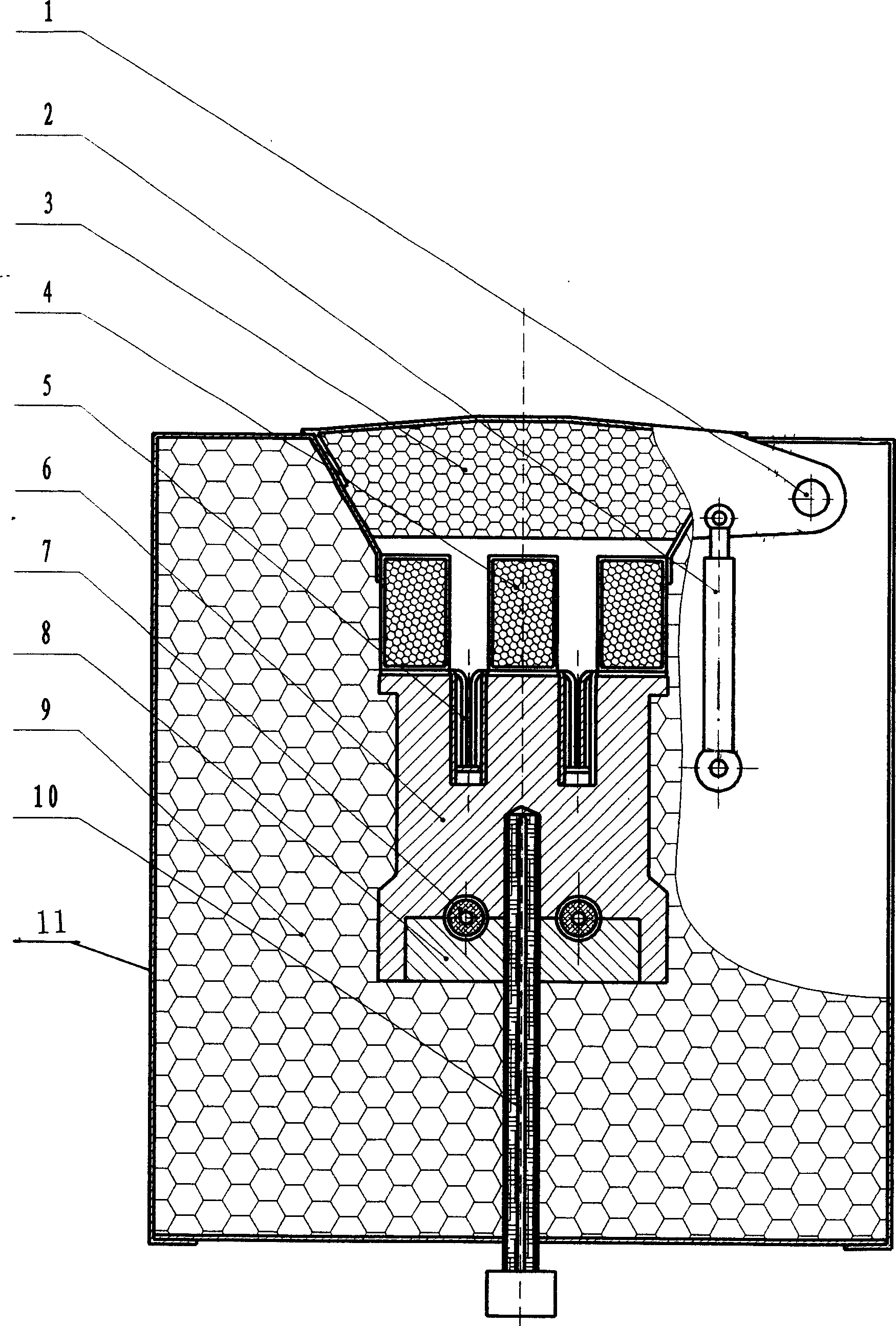

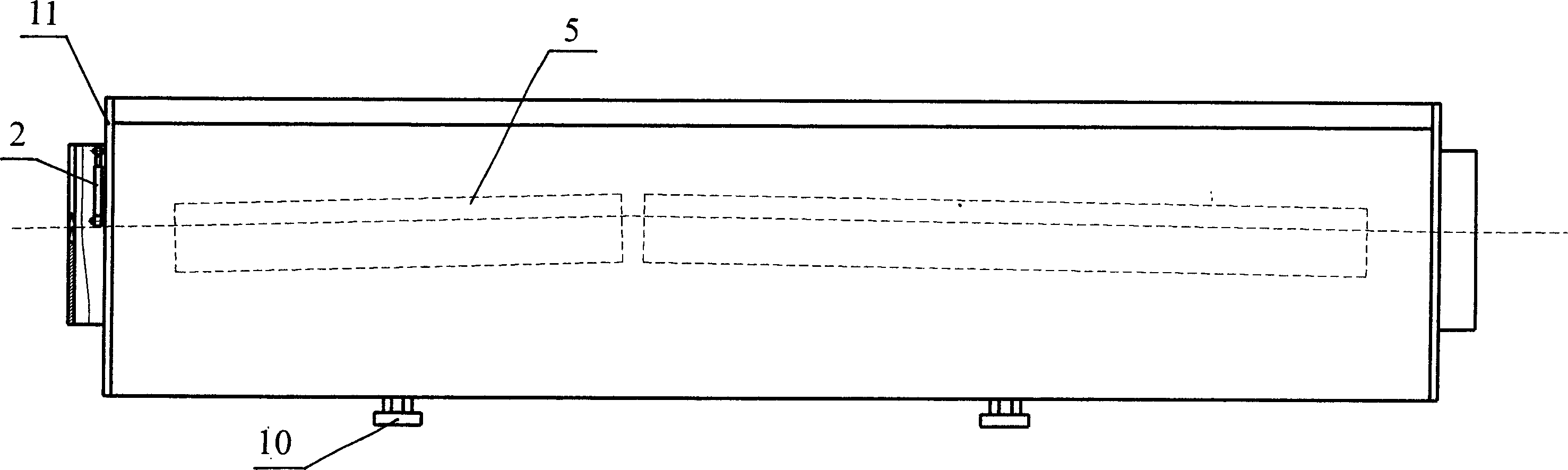

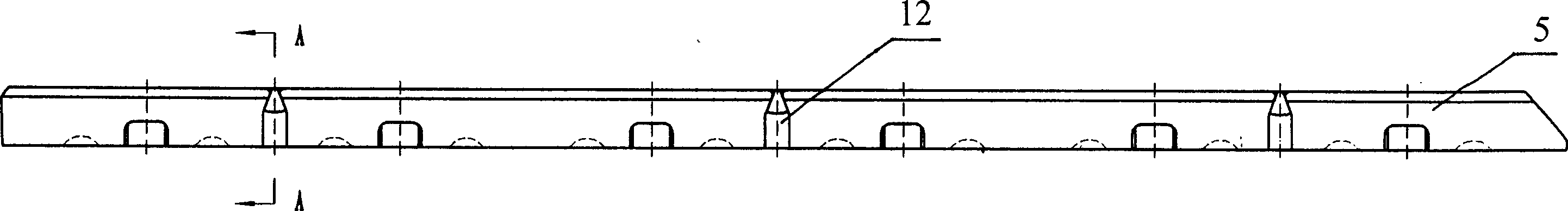

[0024] Below in conjunction with accompanying drawing, embodiment of the present invention is described in further detail:

[0025] The present invention comprises box body 11, and box body 11 is cuboid, and its box body 11 is provided with electric heating rod 7, hot rail 5, heat spreader 6, temperature measuring device 10 and insulation material 9. The heat spreader 6 is a copper heat conductor, and the electric heating rod 7 and the hot rail 5 are respectively embedded in the grooves of the heat spreader 6 , and are fixed in the box body 11 by the heat spreader 6 . In order to replace the electric heating rod 7 conveniently, the lower side of the electric heater 6 is also provided with a heat spreader bottom cover 8 for loading and unloading the electric heating rod 7 . An insulating material 9 is filled between the heat spreader 6 and the box body 11 . In order to effectively test and observe the temperature in the casing 11, a temperature detector 10 is also provided in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com