Shaping device for production of stone insulation integrated board

A technology of stone boards and integrated boards, applied in the direction of stamping machines, presses, manufacturing tools, etc., can solve the problems of low shaping accuracy, damage to the board surface, and inability to adapt, and achieve the effect of saving equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

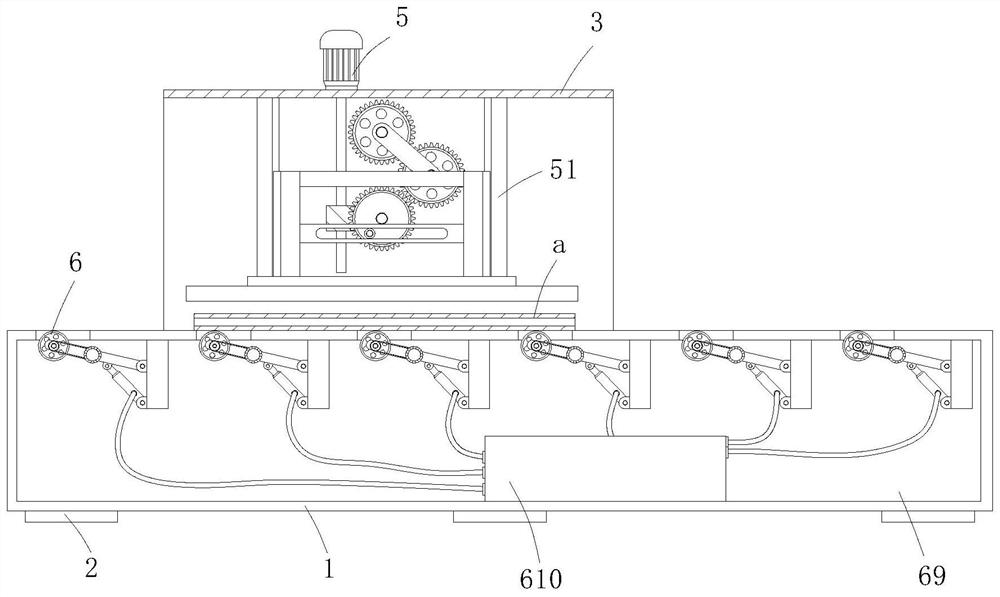

[0037] A shaping device for the production of stone thermal insulation integrated boards, comprising a strip-shaped base box 1 and a plurality of supporting feet 2 installed at the lower end of the strip-shaped base box 1, and a stone plate transmission mechanism 6 is provided on the upper part of the inner cavity of the strip-shaped base box 1, And the upper end of the bar-shaped base box 1 is provided with a stone plate shaping room 3, and a stone plate shaping mechanism 5 is arranged in the stone plate shaping room 3;

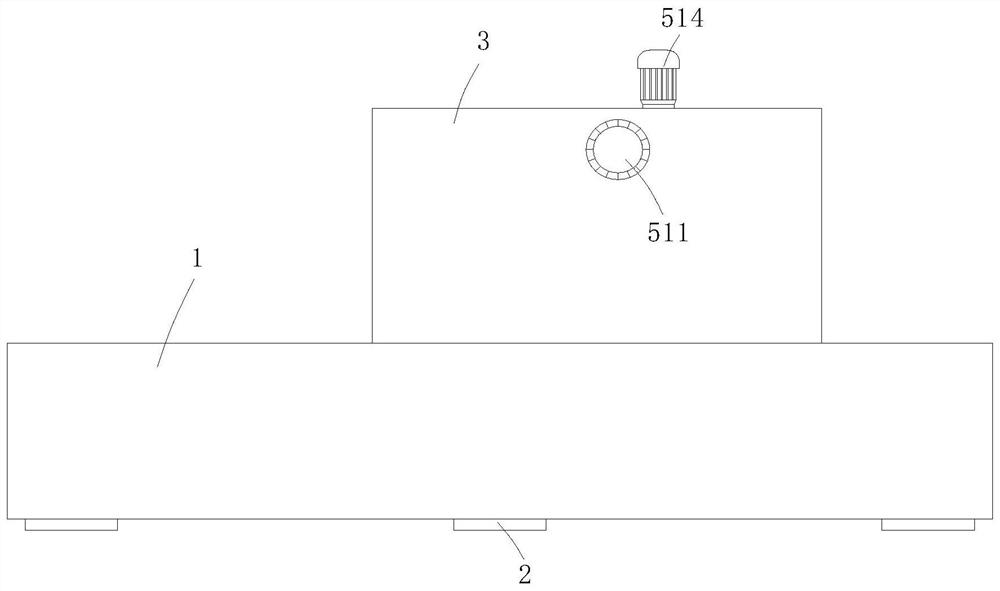

[0038] In this example, if Figure 2-5 As shown, the stone slab sizing mechanism 5 includes a rectangular frame 52 vertically arranged in the inner cavity of the stone slab sizing chamber 3, and the lower end of the rectangular frame 52 is equipped with a sizing press plate 53, and both sides of the rectangular frame 52 are symmetrically provided with slides. rail 51, and the slide rail 51 is fixedly installed on the inner top wall of the stone slab shaping ...

Embodiment 2

[0051] The difference between this embodiment and embodiment 1 is that, as figure 2 and 6 As shown, the hydraulic base of the hydraulic rod 68 is penetrated with a high-pressure oil pipe 69, and the other ends of the multiple high-pressure oil pipes 69 are installed on the oil delivery end of the hydraulic station 610, and the same hydraulic station 610 is used to drive, effectively The cost of equipment is saved, and the use of the hydraulic station 610 can ensure that multiple hydraulic rods 68 are powered synchronously, thereby ensuring the synchronous lifting of multiple transmission rollers 62, which facilitates the stable transmission of the stone plate a.

[0052] Refer to Example 1 for other undescribed structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com