Elastic edge wrapping belt processing technique

The invention relates to a processing technology and technology for edge wrapping, which is applied to the processing technology field of elastic edge wrapping tape, and can solve the problems of wrinkles, affecting aesthetics and practicability, and long processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

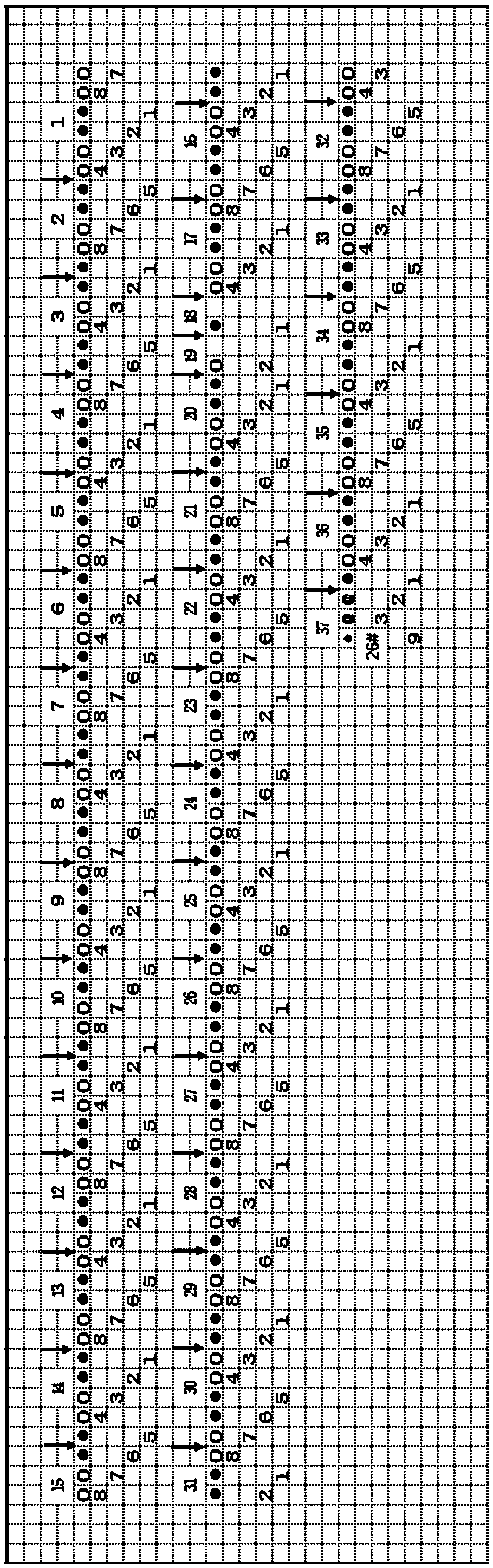

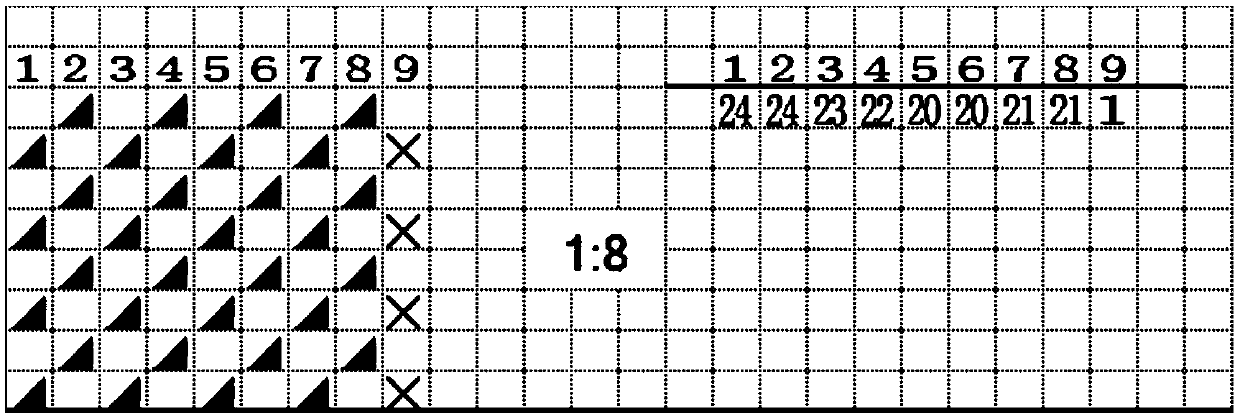

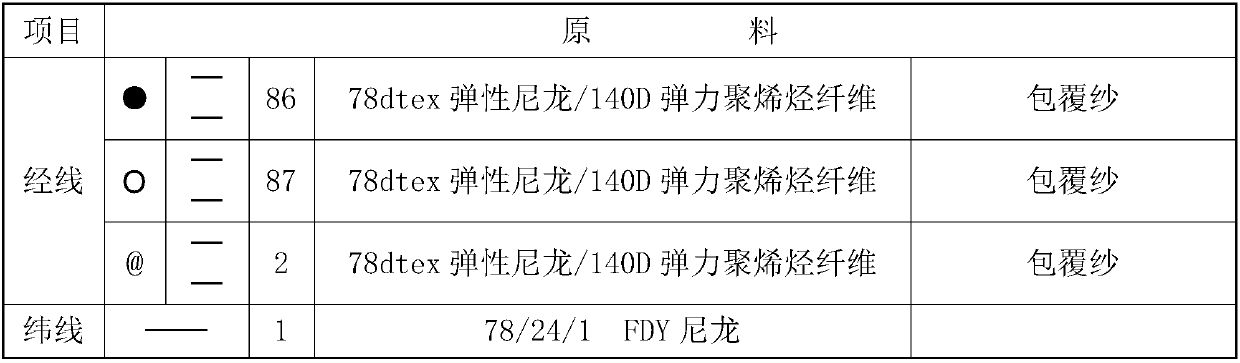

Embodiment 1

[0062] A processing technology for an elastic edging belt, comprising:

[0063] Material preparation step: select the elastic polyolefin fiber for subsequent use;

[0064] Relaxation and retraction step: the elastic polyolefin fiber is processed from a tight winding state to a relaxed state, and after static storage, the elastic polyolefin fiber is retracted; the elastic polyolefin fiber is stretched from the bobbin in the tight winding state , unwinding into a relaxed state; the static storage time is h, h≥48 hours, so that the elastic polyolefin fiber can fully retract naturally under static force.

[0065] Presetting step: After the relaxation and retraction step is completed, the elastic polyolefin fiber is baked in an oven to preform the elastic polyolefin fiber; the baking temperature is 180° C., and the baking time is 30 minutes.

[0066] Covered yarn step: After the presetting step is completed, the elastic polyolefin fiber is coated on the nylon to obtain a covered y...

Embodiment 2

[0072] A processing technology for an elastic edging belt, comprising:

[0073] Material preparation step: select the elastic polyolefin fiber for subsequent use;

[0074] Relaxation and retraction step: the elastic polyolefin fiber is processed from a tight winding state to a relaxed state, and after static storage, the elastic polyolefin fiber is retracted; the elastic polyolefin fiber is stretched from the bobbin in the tight winding state , unwinding into a relaxed state; the static storage time is h, h≥48 hours, so that the elastic polyolefin fiber can fully retract naturally under static force.

[0075] Presetting step: After the relaxation and retraction step is completed, the elastic polyolefin fiber is baked in an oven to preform the elastic polyolefin fiber; the baking temperature is 180° C., and the baking time is 30 minutes.

[0076] Covered yarn step: After the presetting step is completed, the elastic polyolefin fiber is coated on the nylon to obtain a covered y...

Embodiment 3

[0083] A processing technology for an elastic edging belt, comprising:

[0084] Material preparation step: select the elastic polyolefin fiber for subsequent use;

[0085] Relaxation and retraction step: the elastic polyolefin fiber is processed from a tight winding state to a relaxed state, and after static storage, the elastic polyolefin fiber is retracted; the elastic polyolefin fiber is stretched from the bobbin in the tight winding state , unwinding into a relaxed state; the static storage time is h, h≥48 hours, so that the elastic polyolefin fiber can fully retract naturally under static force.

[0086] Presetting step: After the relaxation and retraction step is completed, the elastic polyolefin fiber is baked in an oven to preform the elastic polyolefin fiber; the baking temperature is 180° C., and the baking time is 30 minutes.

[0087] Covered yarn step: after the presetting step is completed, the elastic polyolefin fiber is coated on the nylon to obtain a covered y...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com