A processing technology of elastic edging belt

A processing technology and edge-wrapping technology, applied in the processing of textile materials, heating/cooling of fabrics, textiles, etc., can solve problems affecting aesthetics and practicability, wrinkles, and long processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

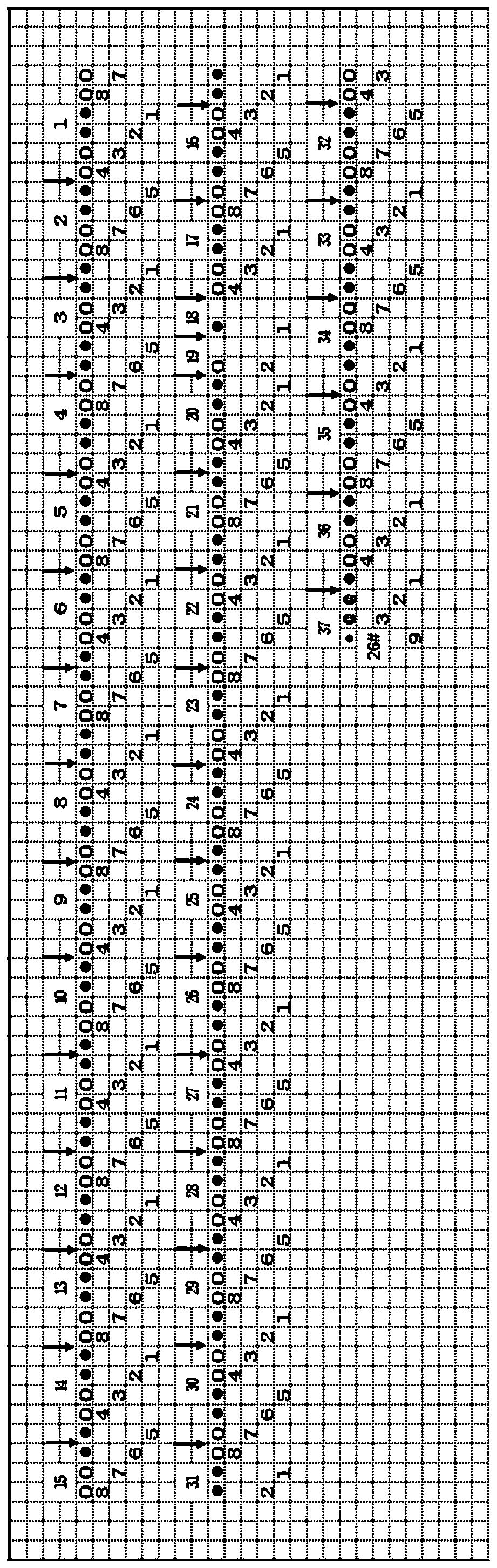

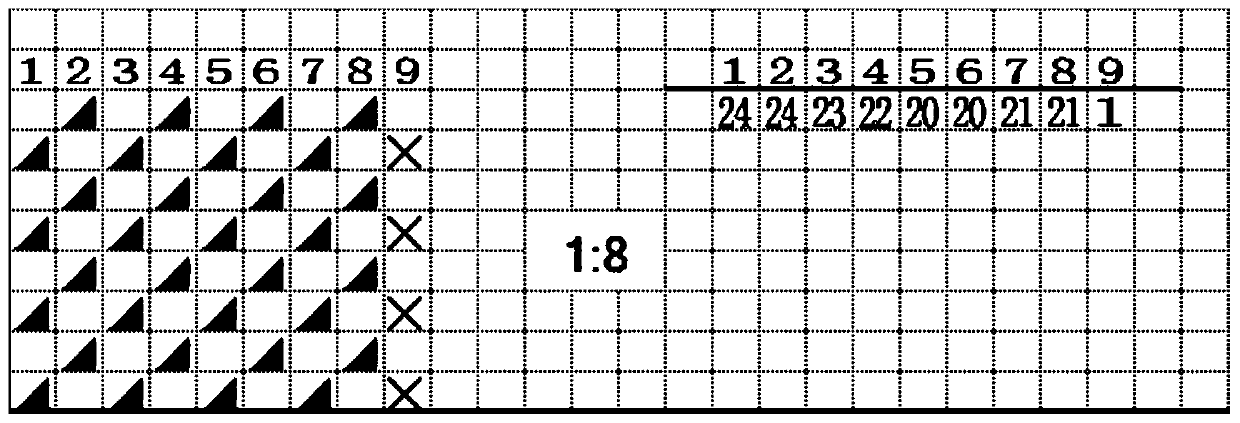

Image

Examples

Embodiment 1

[0062] A processing technology of elastic edging belt, including:

[0063] Material preparation steps: select elastic polyolefin fibers for use;

[0064] Relaxation and retraction step: the elastic polyolefin fiber is processed from the tightly wound state to the relaxed state, and after static storage, the elastic polyolefin fiber is retracted; the elastic polyolefin fiber is used to remove the elastic polyolefin fiber from the tightly wound bobbin The upper, unwinding into a relaxed state; the static storage time is h, h≥48 hours, so that the elastic polyolefin fiber can fully statically retract.

[0065] Pre-forming step: After completing the relaxation and retraction step, the elastic polyolefin fiber is placed in an oven for baking, so that the elastic polyolefin fiber is pre-shaped; the baking temperature is 180° C., and the baking time is 30 minutes.

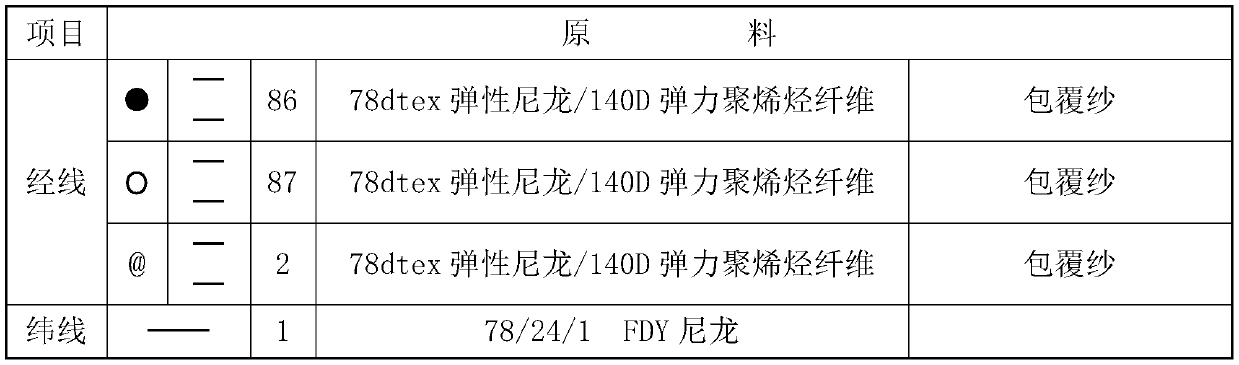

[0066] Covering yarn step: After completing the predetermined step, the elastic polyolefin fiber is wrapped on nylon to obtain ...

Embodiment 2

[0072] A processing technology of elastic edging belt, including:

[0073] Material preparation steps: select elastic polyolefin fibers for use;

[0074] Relaxation and retraction step: the elastic polyolefin fiber is processed from the tightly wound state to the relaxed state, and after static storage, the elastic polyolefin fiber is retracted; the elastic polyolefin fiber is used to remove the elastic polyolefin fiber from the tightly wound bobbin The upper, unwinding into a relaxed state; the static storage time is h, h≥48 hours, so that the elastic polyolefin fiber can fully statically retract.

[0075] Pre-forming step: After completing the relaxation and retraction step, the elastic polyolefin fiber is placed in an oven for baking, so that the elastic polyolefin fiber is pre-shaped; the baking temperature is 180° C., and the baking time is 30 minutes.

[0076] Covering yarn step: After completing the predetermined step, the elastic polyolefin fiber is wrapped on nylon to obtain ...

Embodiment 3

[0083] A processing technology of elastic edging belt, including:

[0084] Material preparation steps: select elastic polyolefin fibers for use;

[0085] Relaxation and retraction step: the elastic polyolefin fiber is processed from the tightly wound state to the relaxed state, and after static storage, the elastic polyolefin fiber is retracted; the elastic polyolefin fiber is used to remove the elastic polyolefin fiber from the tightly wound bobbin The upper, unwinding into a relaxed state; the static storage time is h, h≥48 hours, so that the elastic polyolefin fiber can fully statically retract.

[0086] Pre-forming step: After completing the relaxation and retraction step, the elastic polyolefin fiber is placed in an oven for baking, so that the elastic polyolefin fiber is pre-shaped; the baking temperature is 180° C., and the baking time is 30 minutes.

[0087] Covering yarn step: After completing the predetermined step, the elastic polyolefin fiber is wrapped on nylon to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com