Aniline black pigment producing method

A production method and nigrosine technology, applied in the direction of organic dyes, etc., can solve the problems of reddish color light and low yield of pigments, and achieve the effects of pure color light, high catalytic activity and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

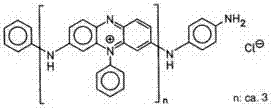

Image

Examples

Embodiment 1

[0026] Add 200ml of water into a 500ml three-necked bottle, add 12g of hydrochloric acid with a weight percentage of 30%, add dropwise 9.9g of aniline under stirring, after fully dissolving, add 0.28g (2.8% of the weight of aniline) copper hydroxyphosphate catalyst, and heat up to 45 ℃, drop 40 grams of 30% hydrogen peroxide solution by weight, complete the dropwise addition in 35-40 minutes, incubate at 50 ℃ for 1 hour, filter, wash the filter cake with about 500ml water until colorless, in 140 ℃ After drying for 2 hours, 9.5 grams of nigrosine was obtained. The yield was 96% based on aniline, and the shade was blue light black.

Embodiment 2

[0028] Add 200ml of water to a 500ml three-necked bottle, add 12g of 30% hydrochloric acid by weight, add 9.9g of aniline dropwise under stirring, after fully dissolving, add 0.05g (0.5% of the weight of aniline) copper hydroxyphosphate catalyst, and heat up to 50 ℃, dropwise add 35 grams of 30% hydrogen peroxide solution by weight, complete the dropwise addition within 45-50 minutes, keep warm at 55℃ for 2 hours, filter, wash the filter cake with about 500ml water until colorless, and heat it at 140℃ Drying at high temperature for 2 hours gave 9.0 g of nigrosine, with a yield of 91%, and the shade was blue light black.

Embodiment 3

[0030] Add 200ml of water into a 500ml three-necked bottle, add 12g of hydrochloric acid with a weight percentage of 30%, add dropwise 9.9g of aniline under stirring, after it is completely dissolved, add 0.1g (1% of the weight of aniline) copper hydroxyphosphate catalyst, and heat up to 35 ℃, drop 35 grams of 30% hydrogen peroxide solution by weight, add dropwise within about 15-20 minutes, keep warm at 35 ℃ for 1.5 hours, filter, wash the filter cake with 500ml water until colorless, in 140 ℃ Drying at lower temperature for 2 hours gave 9.3 grams of nigrosine, with a yield of 94%, and the shade was blue light black.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com