Dyeing process of far-infrared antibacterial fabric

An antibacterial fabric and far-infrared technology, which is applied to the dyeing process of far-infrared antibacterial fabrics, can solve the problems of increased cost, waste water discharge, low dyeing fastness, etc., and achieve the effects of shortened production time, good homochromaticity and pure color light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

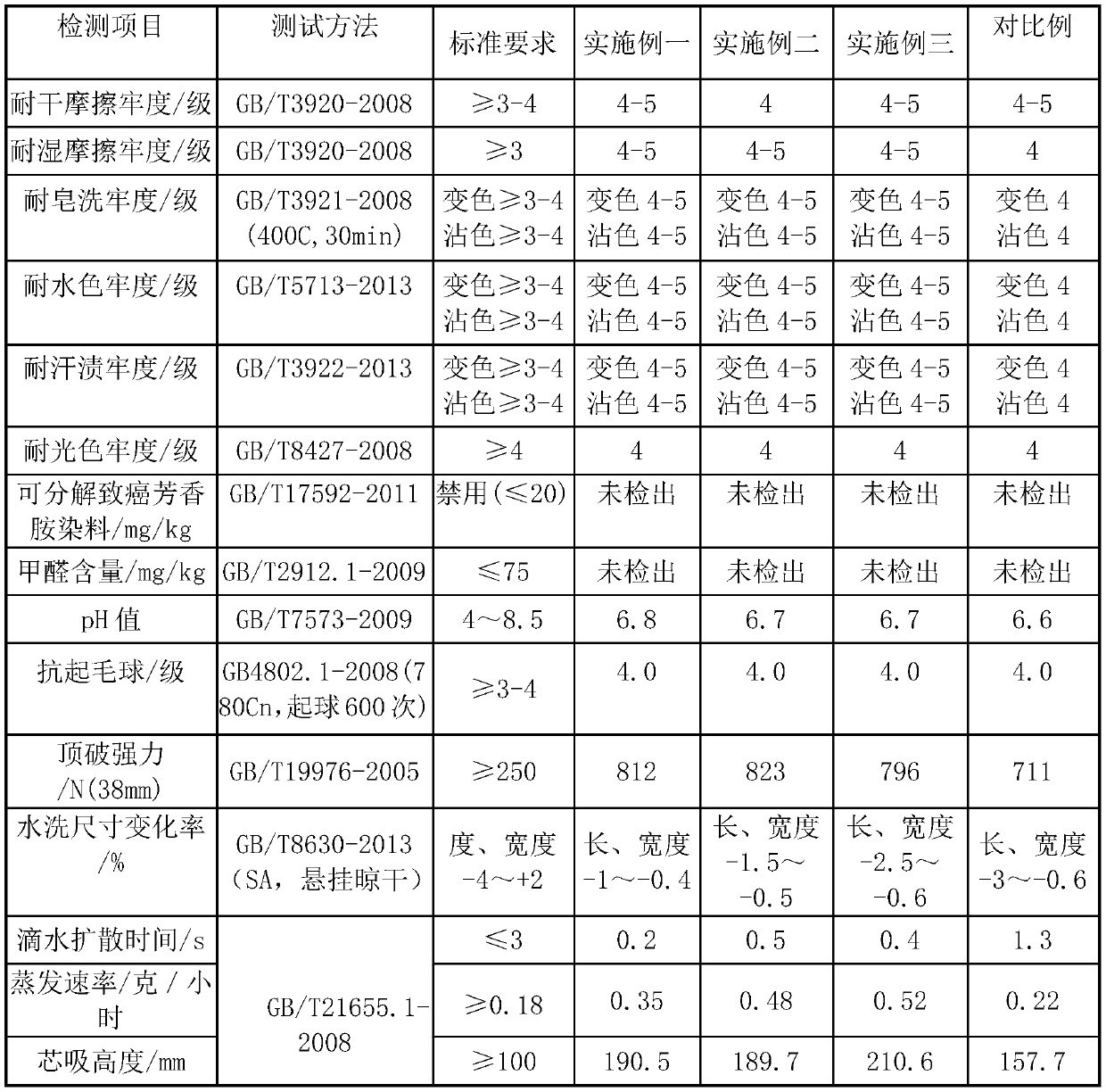

Embodiment 1

[0023] The dyeing process of a kind of far-infrared antibacterial fabric involved in the present embodiment comprises the following steps: (1) preparation of gray cloth, (2) pre-dyeing treatment, (3) dyeing, (4) post-soaping treatment and (5) Finishing after styling.

[0024] In the preparation of the gray cloth in step (1), the gray cloth is woven with 75D / 72F germanium-containing polyester yarn and spandex core-spun yarn with a double-sided circular knitting machine at a density of 20-25 needles per inch. The spandex covered yarn is 2.2tex spandex filament covered with 40s combed cotton yarn.

[0025] In step (2) pre-dyeing treatment: the fabric is placed in the pre-dyeing treatment solution with a liquor ratio of 1:15-20 and heated to 60-70°C; the pre-dyeing treatment solution includes degreaser, penetrating agent, anti-wrinkle agent in the bath, water softener, low-temperature refining agent TF-189; the added water softener makes the water hardness 5-7.

[0026] The cont...

Embodiment 2

[0034] The dyeing process of a kind of far-infrared antibacterial fabric involved in the present embodiment comprises the following steps: (1) preparation of gray cloth, (2) pre-dyeing treatment, (3) dyeing, (4) post-soaping treatment and (5) Finishing after styling.

[0035] In the preparation of the gray cloth in step (1), the gray cloth is woven with 75D / 72F germanium-containing polyester yarn and spandex core-spun yarn with a double-sided circular knitting machine at a density of 20-25 needles per inch. The spandex covered yarn is 2.2tex spandex filament covered with 40s combed cotton yarn.

[0036] In step (2) pre-dyeing treatment: the fabric is placed in the pre-dyeing treatment solution with a liquor ratio of 1:15-20 and heated to 60-70°C; the pre-dyeing treatment solution includes degreaser, penetrating agent, anti-wrinkle agent in the bath, water softener, low-temperature refining agent TF-189; the added water softener makes the water hardness 5-7.

[0037] The cont...

Embodiment 3

[0045] The dyeing process of a kind of far-infrared antibacterial fabric involved in the present embodiment comprises the following steps: (1) preparation of gray cloth, (2) pre-dyeing treatment, (3) dyeing, (4) post-soaping treatment and (5) Finishing after styling.

[0046] In the preparation of the gray cloth in step (1), the gray cloth is woven with 75D / 72F germanium-containing polyester yarn and spandex core-spun yarn with a double-sided circular knitting machine at a density of 20-25 needles per inch. The spandex covered yarn is 2.2tex spandex filament covered with 40s combed cotton yarn.

[0047] In step (2) pre-dyeing treatment: the fabric is placed in the pre-dyeing treatment solution with a liquor ratio of 1:15-20 and heated to 60-70°C; the pre-dyeing treatment solution includes degreaser, penetrating agent, anti-wrinkle agent in the bath, water softener, low-temperature refining agent TF-189; the added water softener makes the water hardness 5-7.

[0048] The cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com