Dyeing process for treasure island suede microfiber leather and wastewater recycle technique in dyeing process

A technology of microfiber leather and suede, applied in suede microfiber leather and the field, can solve the problems of solvent volatilization, damage to the environment and surrounding operators, difficult to recycle, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

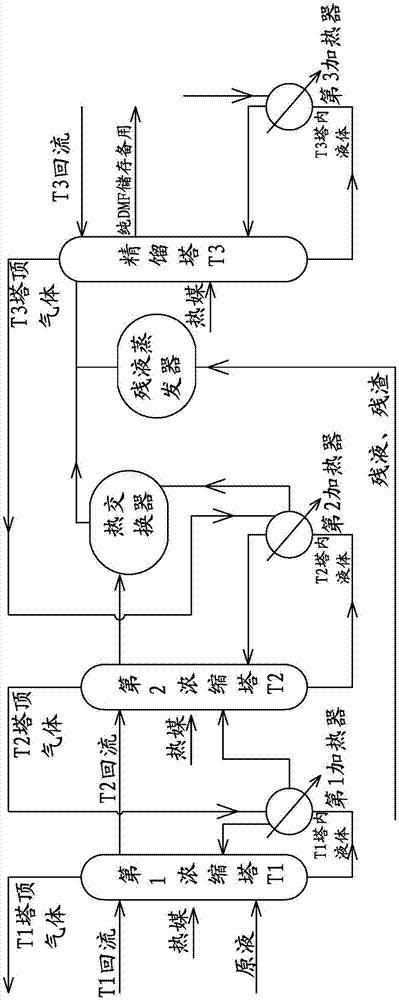

Image

Examples

Embodiment Construction

[0021] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

[0022] In the dyeing process of the Baodao suede superfiber skin of the present invention, firstly, the raw materials are mainly prepared into Baodao fibers through pre-spinning treatment, blended spinning and fiber post-spinning. Pre-spinning treatment, blended spinning and fiber post-spinning can use the existing technology and related equipment. This case mainly describes the differences between the pre-spinning treatment, blended spinning and fiber post-spinning, which are the same as the existing technology. , will not be repeated here.

[0023] Pre-spinning treatment is mainly to prepare for the following steps, such as raw materials are processed by batching, metering, mixing and other processes. Raw materials can use existing polyamide (commonly known as nylon, nylon, PA6 chips), low-density polyethyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com