Dyeing-accelerating anti-staining agent for acid dye dyeing of chinlon and spandex fabrics and synthesis method of dyeing-accelerating anti-staining agent

A synthesis method and technology of acid dyes, applied in the field of dye-promoting and anti-staining agent and its synthesis, and dye-promoting agent, can solve the problems of fabric color difference and hand feeling effect, increase process steps, etc., so as to reduce the dye uptake rate and improve the dye uptake rate. , Improve the effect of dyeing efficiency and process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

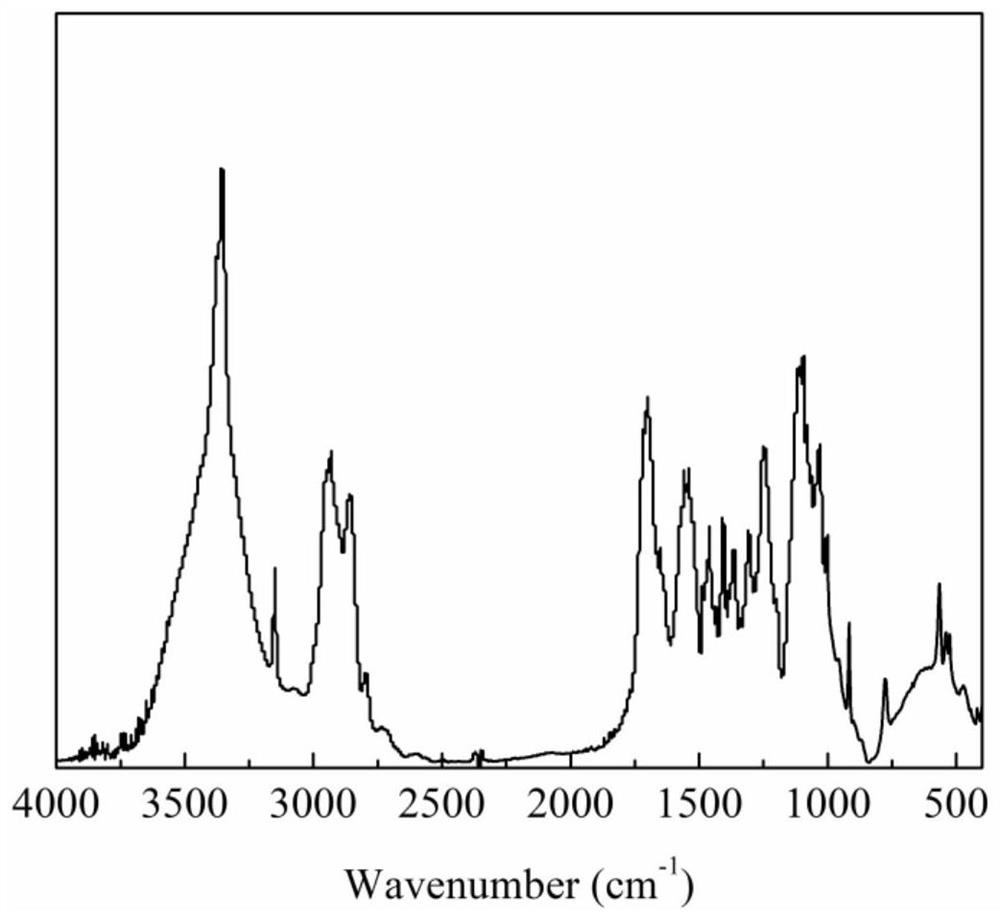

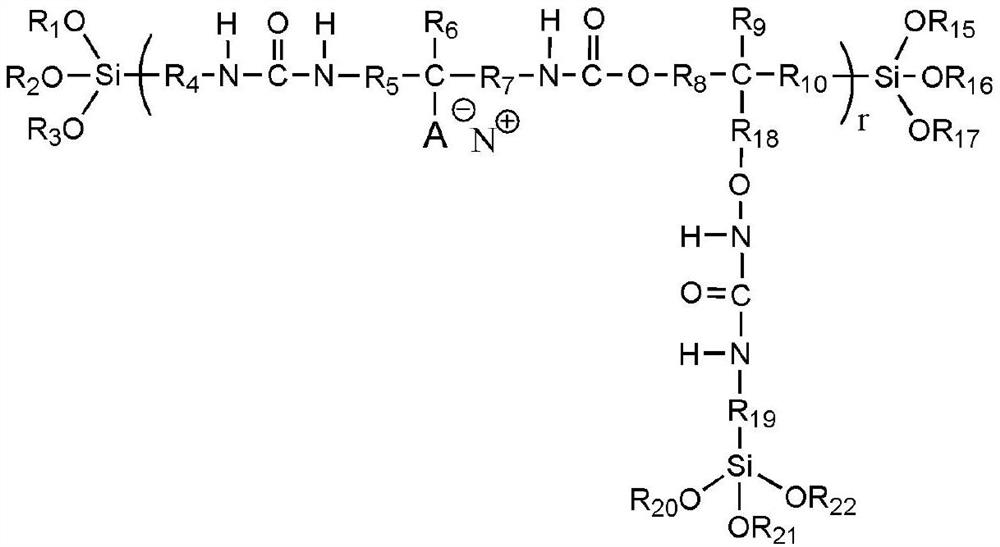

Method used

Image

Examples

Embodiment 1

[0033] A three-necked flask equipped with a condenser and a stirrer was used as the reaction vessel.

[0034] (1) Add 4.61g of isophorone diisocyanate dropwise to 10.00g of polytetrahydrofuran with a number average molecular weight of 1000, mix and stir, and add 1 drop of dibutyltin dilaurate, stir the three evenly, and heat to 80°C. After reacting for 1.5h, the temperature was lowered to 70°C after obtaining the prepolymerized product.

[0035] (2) Dissolve 3.35g of 2,2-dimethylolpropionic acid and 2.41g of 1,4-butanediol in 8.85g of N-methylpyrrolidone to make a mixed chain extender solution, and make the mixed chain extender solution Add dropwise to the prepolymerized product in step (1) through a constant pressure funnel, keep at 70°C, react for 1.5-2 hours to obtain a chain extension product, and lower the temperature to 35°C.

[0036] (3) Add 1.20 g of γ-aminopropyltriethoxysilane dropwise to the chain-extended product in step (2), stir, keep at 35° C., and react for 1 ...

Embodiment 2

[0040] A three-necked flask equipped with a condenser and a stirrer was used as the reaction vessel.

[0041] (1) Add 4.20g of hexamethylene diisocyanate dropwise to 22.00g of polytetrahydrofuran with a number average molecular weight of 2000, mix and stir, and add 1 drop of dibutyltin dilaurate, stir the three evenly, and heat to 90°C, After reacting for 2 hours, the temperature was lowered to 75° C. after obtaining the prepolymerized product.

[0042] (2) 4.45g 2,2-dimethylol butyric acid and 1.80g 1,4-butanediol and 1.34g trimethylolpropane are dissolved in 15g N-methylpyrrolidone to make a mixed chain extender solution, The mixed chain extender solution was added dropwise to the prepolymerized product in step (1) through a constant pressure funnel, kept at 75°C, and reacted for 1.5h to obtain the chain extended product, and the temperature was lowered to 45°C.

[0043] (3) Add 1.34 g of γ-aminopropyltriethoxysilane dropwise to the chain-extended product in step (2), stir, k...

Embodiment 3

[0046] A three-necked flask equipped with a condenser and a stirrer was used as the reaction vessel.

[0047] (1) Add 4.35g of toluene diisocyanate dropwise to 11.00g of polyethylene glycol with a number average molecular weight of 1000, mix and stir, and add 1 drop of dibutyltin dilaurate, stir the three evenly, heat to 85°C, and react After 1.5 hours, the prepolymerization product was obtained and the temperature was lowered to 65°C.

[0048] (2) Dissolve 4.02g of 2,2-dimethylolpropionic acid and 2.36g of 1,6-hexanediol in 10g of N-methylpyrrolidone to make a mixed chain extender solution, pass the mixed chain extender solution through The constant pressure funnel was added dropwise to the prepolymerization product in step (1), kept at 65°C, and reacted for 1.5h to obtain the chain extension product, and the temperature was lowered to 40°C.

[0049] (3) Add 1.18 g of γ-glycidoxypropyltrimethoxysilane dropwise to the chain extension product in step (2), stir, keep at 40°C, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com