Horseradish peroxidase catalytic dyeing method for cotton fabric

A technology for horseradish peroxidase and horseradish peroxide, which is applied in the field of textile dyeing and finishing to achieve the effects of reducing energy consumption, reducing water pollution pressure and low dyeing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017]a, prepare a horseradish peroxidase catalytic dyed bath:

[0018]Yanphenol, 2,5-diaminophenylsulfonic acid, horseradish peroxidase, hydrogen peroxide were mixed with water, and stir evenly to obtain a horseradish peroxidase catalytic dyed bath. The ratio of phthalphenols, 2,5-diaminophenylbenzenesulfonic acid is 1: 3, and the horseradish peroxidase addition is 0.2 g / L, 27% hydrogen peroxide addition amount is 2 ml / L, adjust the pH. Take 5.

[0019]b, dyeing:

[0020]In the oscillation water bath of 50-70 r / min, a horseradish peroxidase catalyzed a toner to 45 ° C, and a cotton fabric that was wetted in advance was put into a horseradish peroxidase catalytic dyed bath for 2 h. The bath ratio is 1:15; use hot water cleaning, the temperature is 50 ° C, the time is 1:15; the bath ratio is 1:15; uses normal warm water, the time is 5 min, the bath ratio is 1:15; dry, the temperature is 80 ° C .

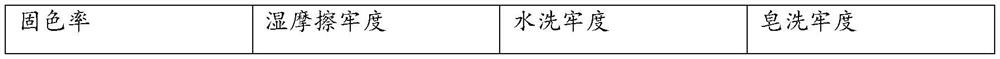

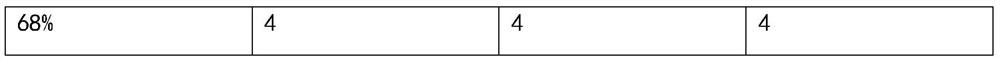

[0021](1) Test: Test of solid color rate, wet friction, water washing fastness, soap washing ...

Embodiment 2

[0027]a, prepare a horseradish peroxidase catalytic dyed bath:

[0028]Yanphenol, 2,5-diaminophenylsulfonic acid, horseradish peroxidase, hydrogen peroxide were mixed with water, and stir evenly to obtain a horseradish peroxidase catalytic dyed bath. The ratio of phthalphenols, 2,5-diaminophenylbenzenesulfonic acid is 1: 4, and the amount of macama peroxidase is 0.2 g / L, 27% hydrogen peroxide addition is 2mL / L, adjusting the pH Take 5.

[0029]b, dyeing:

[0030]In the oscillation water bath of 50-70 r / min, a horseradish peroxidase catalyzed a toner to 45 ° C, and a cotton fabric that was wetted in advance was put into a horseradish peroxidase catalytic dyed bath for 2 h. The bath ratio is 1:15; use hot water cleaning, the temperature is 50 ° C, the time is 1:15; the bath ratio is 1:15; uses normal warm water, the time is 5 min, the bath ratio is 1:15; dry, the temperature is 80 ° C .

[0031](3) Test: Test of the dyed fabric, wet raw fastness, water washing fastness, soap-washing fastnes...

Embodiment 3

[0037]a, prepare a horseradish peroxidase catalytic dyed bath:

[0038]Yanphenol, 2,5-diaminophenylsulfonic acid, horseradish peroxidase, hydrogen peroxide were mixed with water, and stir evenly to obtain a horseradish peroxidase catalytic dyed bath. The ratio of phthalphenols, 2,5-diaminophenylbenzenesulfonic acid is 1: 5, and the amount of horseradish peroxidase is added to 0.2 g / L, 27% hydrogen peroxide addition is 2mL / L, adjusting the pH. Take 5.

[0039]b, dyeing:

[0040]In the oscillation water bath of 50-70 r / min, a horseradish peroxidase catalyzed a toner to 45 ° C, and a cotton fabric that was wetted in advance was put into a horseradish peroxidase catalytic dyed bath for 2 h. The bath ratio is 1:15; use hot water cleaning, the temperature is 50 ° C, the time is 1:15; the bath ratio is 1:15; uses normal warm water, the time is 5 min, the bath ratio is 1:15; dry, the temperature is 80 ° C .

[0041](3) Test: Test of the dyed fabric, wet raw fastness, water washing fastness, soap-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com