Multifunctional high-temperature oil removing levelling agent

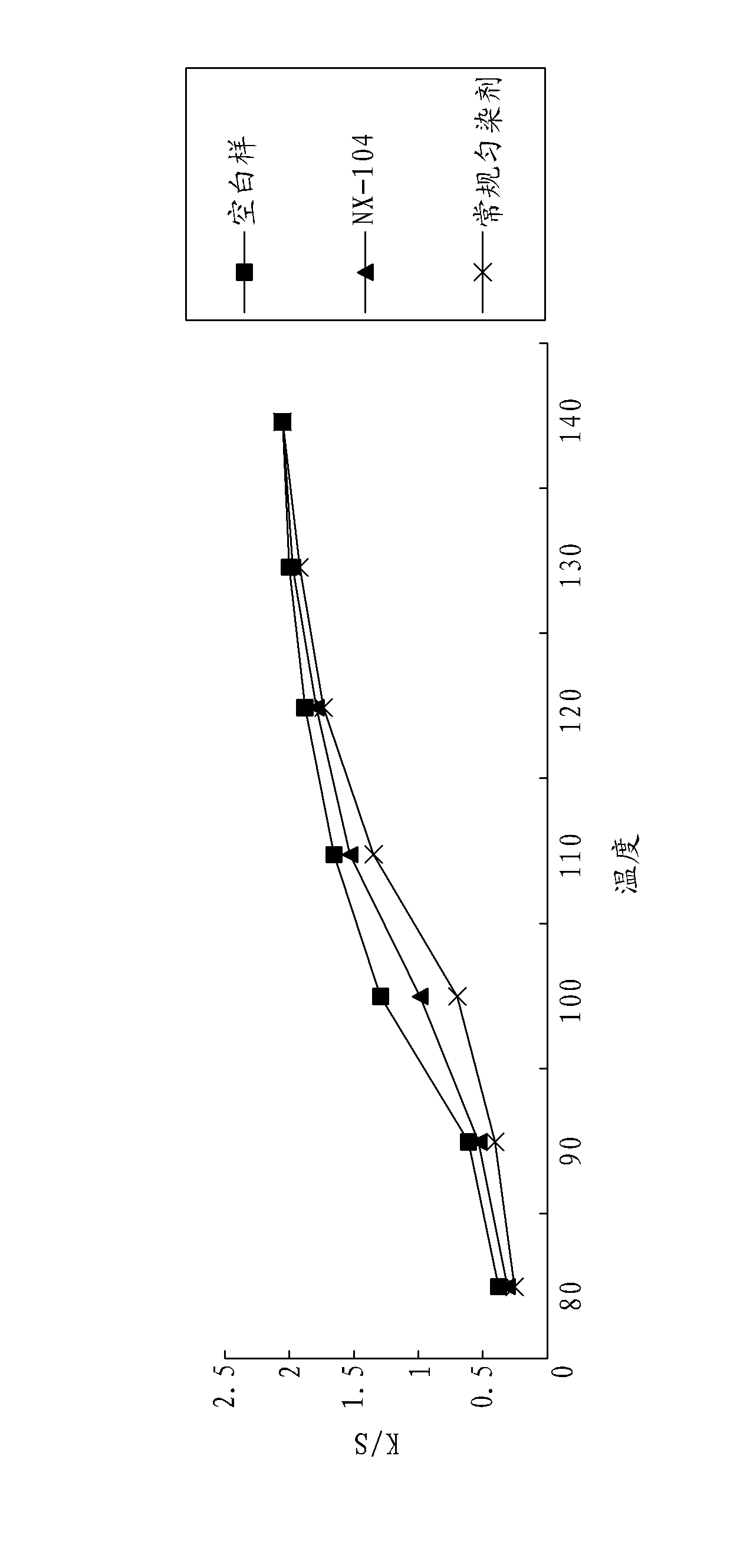

A high-temperature degreasing and multi-functional technology, applied in the field of dyeing and finishing of woven fabrics, can solve the problems of increasing the fabric process and production costs, increasing the burden of discharge treatment, and lack of degreasing functions, etc., to improve the rate of first-class products, The effect of reducing production costs and shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of the multifunctional high-temperature degreasing and leveling agent is realized in the following steps:

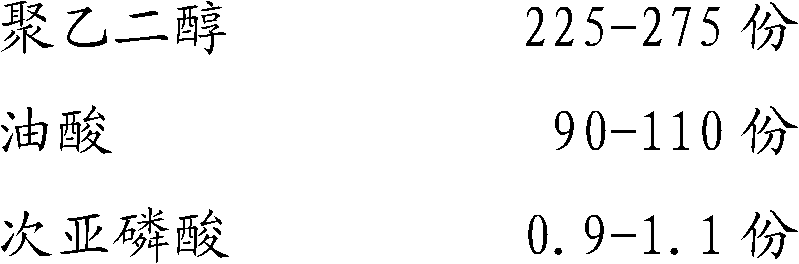

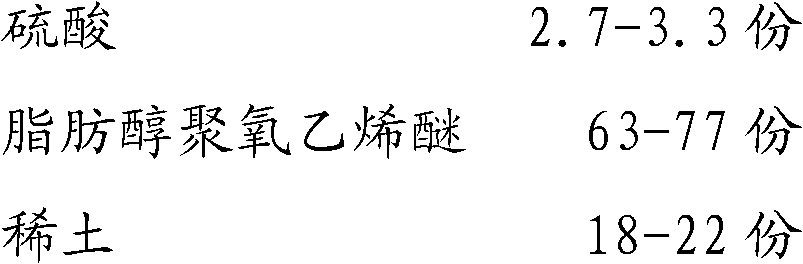

[0020] 1) First mix 225-275 parts by weight of polyethylene glycol and 90-110 parts by weight of oleic acid, then add 2.7-3.3 parts by weight of sulfuric acid and 0.9-1.1 parts by weight of hypophosphorous acid for catalysis, after the esterification reaction generate esters;

[0021] 2) Mix and compound the obtained esterified product with 63-77 parts by weight of fatty alcohol polyoxyethylene ether and 18-22 parts by weight of rare earth to obtain the multifunctional high-temperature degreasing and leveling agent of the present invention.

Embodiment 1

[0023] A multifunctional high-temperature degreasing and leveling agent of the present invention is specifically prepared from the following raw materials in parts by weight: 250 parts by weight of polyethylene glycol, 100 parts by weight of oleic acid, 1 part by weight of hypophosphorous acid, 3 parts by weight Parts of sulfuric acid, 70 parts by weight of fatty alcohol polyoxyethylene ether and 20 parts by weight of rare earth.

[0024] The preparation method of the multifunctional high-temperature degreasing and leveling agent is realized in the following steps:

[0025] 1) Mix 250 parts by weight of polyethylene glycol and 100 parts by weight of oleic acid, then add 3 parts by weight of sulfuric acid and 1 part by weight of hypophosphorous acid for catalysis, and generate esterified products after the esterification reaction;

[0026] 2) Mix and compound the obtained esterified product with 70 parts by weight of fatty alcohol polyoxyethylene ether and 20 parts by weight of...

Embodiment 2

[0028] A multifunctional high-temperature degreasing and leveling agent of the present invention is specifically prepared from the following raw materials in parts by weight: 225 parts by weight of polyethylene glycol, 95 parts by weight of oleic acid, 1 part by weight of hypophosphorous acid, 2.7 parts by weight The sulfuric acid of part, the fatty alcohol polyoxyethylene ether of 65 parts by weight and the rare earth of 18 parts by weight.

[0029] The preparation method of the multifunctional high-temperature degreasing and leveling agent is realized in the following steps:

[0030] 1) First mix 225 parts by weight of polyethylene glycol and 95 parts by weight of oleic acid, then add 2.7 parts by weight of sulfuric acid and 1 part by weight of hypophosphorous acid for catalysis, and generate esterified products after the esterification reaction;

[0031] 2) Mix and compound the obtained esterified product with 65 parts by weight of fatty alcohol polyoxyethylene ether and 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com