Process for synthesizing iron oxide brown

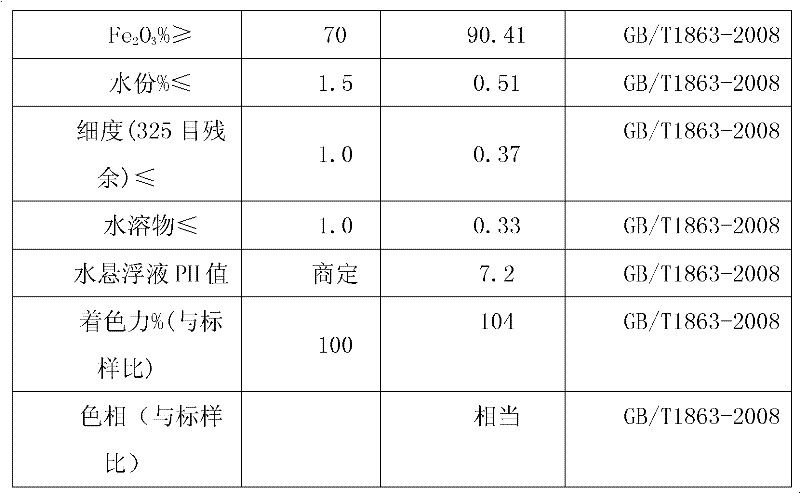

A synthesis process, iron brown technology, applied in the direction of iron oxide/hydroxide, etc., can solve the problems of unstable product quality, uneven hue, etc., and achieve the effect of convenient operation, pure color and light, and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A kind of synthetic technique of iron palm, is characterized in that: comprise the following steps:

[0021] (1), add ferrous sulfate solution in the reactor, and then according to the mass ratio NaOH: FeSO 4 =3:1~0.8 Slowly add liquid caustic soda, add liquid caustic soda in three times, each interval is 28-32 minutes, then raise the temperature in the reaction kettle to 75-78°C, the temperature needs to be controlled to increase the temperature by 5°C per hour Carry out until the temperature reaches above 75°C and stop heating up, after 50-70 minutes of heat preservation, add water to dilute the mixed slurry to a solid content of 8-10%;

[0022] (2), slowly add sodium nitrite in the reaction kettle according to the ratio of 45-50KG per ton of product, sodium nitrite is added in three times, each interval is 30-32 minutes, while feeding oxygen, the feeding pressure of oxygen is 10-13em water column, and then turn on the spray equipment to fully mix the slurry, oxygen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com