Electronic device housing and manufacturing method therefor

A manufacturing method and technology of electronic equipment, applied in the direction of casing/cabinet/drawer components, antenna support/installation device, structural form of radiation unit, etc. Antenna signal reception and other issues, to achieve the effect of diverse colors, soft and smooth hand feeling, and strong tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

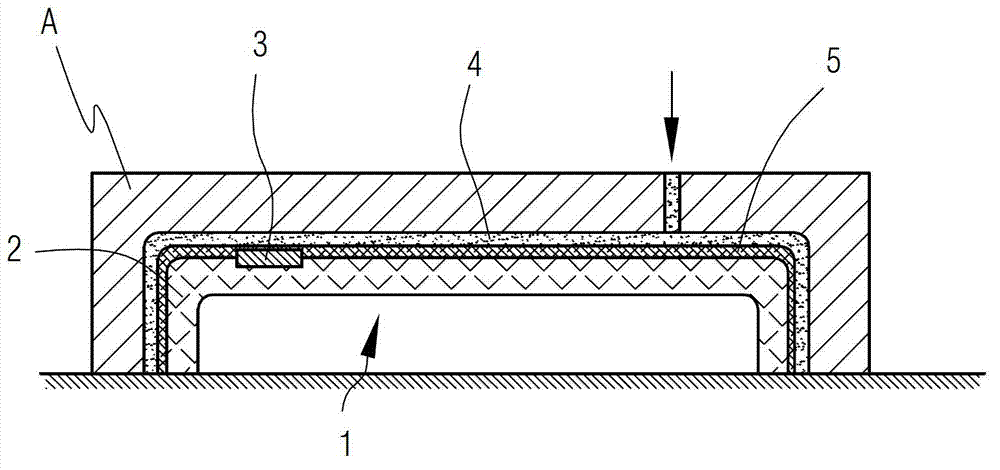

[0025] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Wherein, the same parts adopt the same reference numerals.

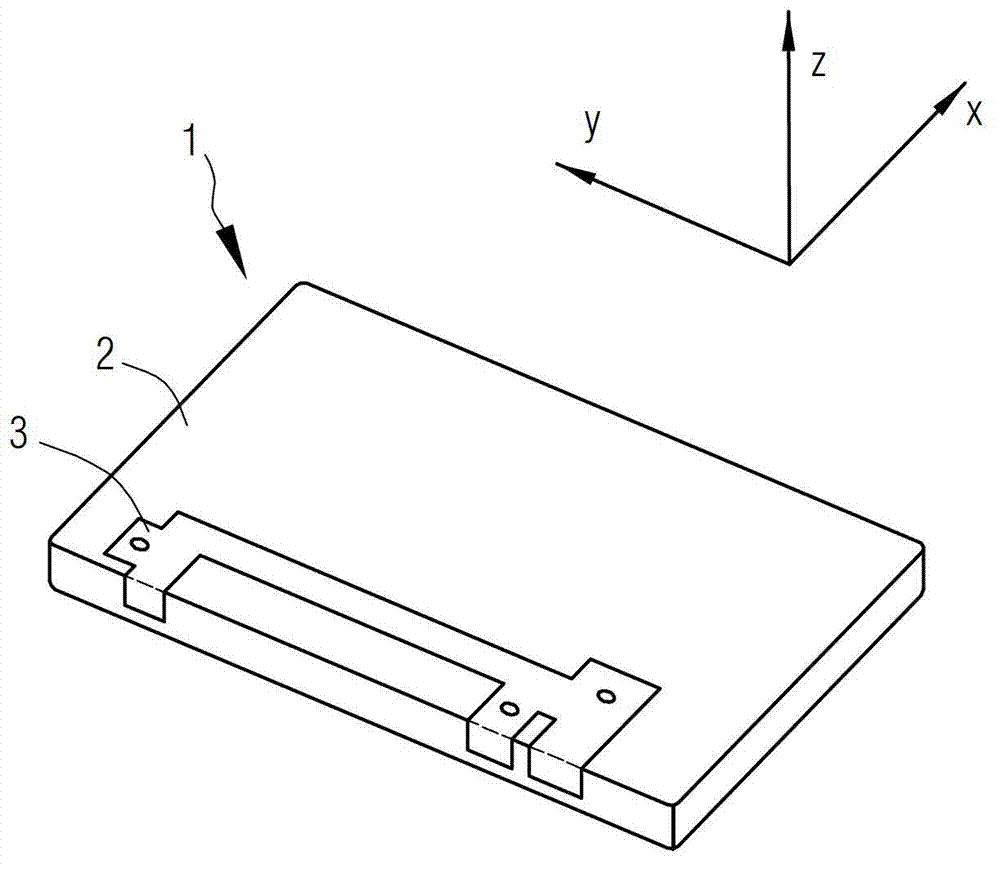

[0026] Taking the back cover of a mobile phone case as an example, the structure and manufacturing method of the electronic device case according to the present invention will be described in detail below. Of course, those skilled in the art should understand that the electronic device housing of the present invention is not limited to mobile phone electronic devices, but can also be widely used in various electronic devices with wireless communication functions, such as mobile phones, computers, and tablet computers. Wait.

[0027] figure 1 Shown is a structural schematic diagram of forming a metal antenna on the surface of an electronic device casing by LDS technology...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com