Preparation method of hydrophilic amino silicone oil

An amino silicone oil, hydrophilic technology, applied in the field of preparation of hydrophilic amino silicone oil, can solve the problems of poor fastness and softness, poor emulsion stability, static electricity, etc. Good electrostatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

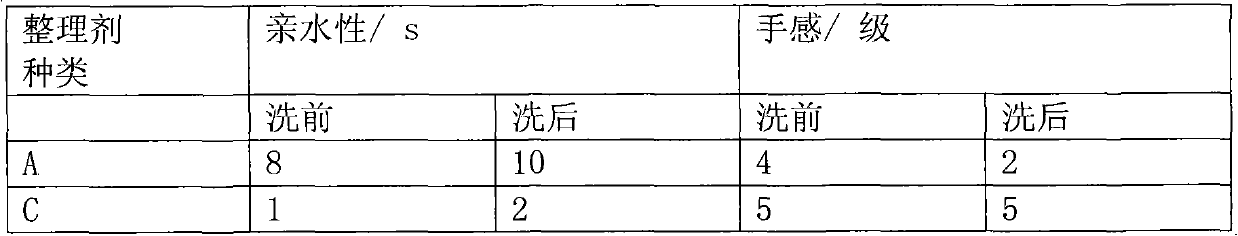

Image

Examples

Embodiment 1

[0034] A. In the reactor equipped with stirring, start stirring, and then add 92 parts of octamethylcyclotetrasiloxane, 3 parts of high hydrogen-containing silicone oil (brand XFC202), 2 parts of end-capping agent (hexamethyldisiloxane Oxygen, grade HX-18), 3 parts of hydrochloric acid, mix evenly, react at 60°C for 11 hours, the material in the reactor turns from muddy to transparent, after the reaction, cool down to 25°C with jacketed cooling water, Adjust the pH to 6 under these conditions, and then take a sample to detect that the hydrogen content is 0.05%, and the viscosity measured by a rotational viscometer is 500mPa.s, and a colorless and transparent low-hydrogen silicone oil is prepared for use in the next step.

[0035] B. Transfer 89.9 parts of low hydrogen-containing silicone oil, 0.1 part of catalyst (chloroplatinic acid, brand NMC2505), and 10 parts of glycidyl ether (alkenyl epoxy compound) into a reactor equipped with a stirrer and connected with a supporting co...

Embodiment 2

[0038] A. In the reactor equipped with stirring, start stirring, and add 92 parts of cyclotetrasiloxane mixture, 3 parts of high hydrogen-containing silicone oil, 2 parts of end-capping agent (hexamethyldisiloxane), 3 parts Parts of phosphoric acid were mixed evenly, and reacted at 100°C for 7 hours. The material in the reactor turned from muddy to transparent. After the reaction, the cooling water in the jacket was used to cool down to 25°C, and then the pH was adjusted to 6 under this condition. The hydrogen content is 0.05%, the viscosity measured by a rotational viscometer is 480mPa.s, and a colorless and transparent low-hydrogen silicone oil is obtained.

[0039] B. Add 89.9 parts of low-hydrogen silicone oil, 0.1 part of catalyst (chloroplatinic acid), and 10 parts of 1-vinyl-3,4-epoxycyclohexane, and stir the reaction for 8 hours at 100°C. Then, the low-boiling point substances were evaporated under the vacuum condition of 0.09MPa to obtain a colorless and transparent e...

Embodiment 3

[0042] A. In the reactor equipped with stirring, start stirring, and add 70 parts of octamethylcyclotetrasiloxane, 25 parts of high hydrogen-containing silicone oil, 2 parts of end-capping agent (hexamethyldisiloxane), Mix 3 parts of sulfuric acid evenly, and react at 120°C for 6 hours. The material in the reactor turns from muddy to transparent. After the reaction, cool down to 25°C with jacketed cooling water, and then adjust the pH to 6 under this condition. The measured hydrogen content is 0.4%, and the viscosity measured by a rotational viscometer is 600 mPa.s, and a colorless and transparent low hydrogen-containing silicone oil is obtained.

[0043] B. Transfer 74.9 parts of low hydrogen-containing silicone oil and 0.1 part of catalyst (chloroplatinic acid) obtained in the previous step into a reactor equipped with a stirrer and connected with a supporting condenser, and add 25 parts of 1-vinyl-3, 4-epoxycyclohexane was reacted at 120°C for 6 hours, and the low boiling p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com