Detachable type dry powder material gasifying tool

A gasification bed and dismantling technology, which is applied in the field of dismountable dry powder material gasification bed, can solve the problems of easy formation of cement plug, low linear velocity, difficulty in cement gasification input pipeline, etc., and achieve uniform and stable gas flow and gasification. The effect of increasing the area and preventing recoil into the gas supply manifold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further disclose the technical solutions of the present invention, the following will be described in detail through examples in conjunction with the accompanying drawings:

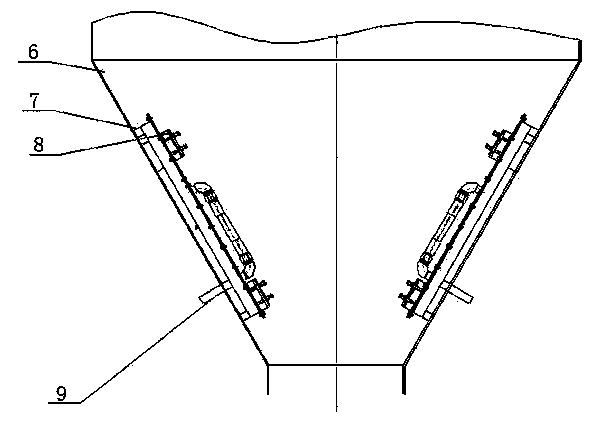

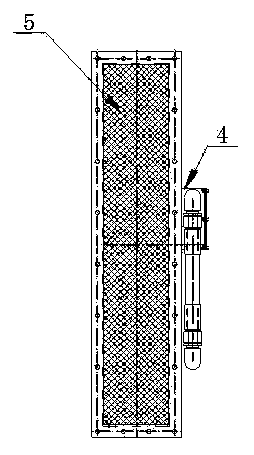

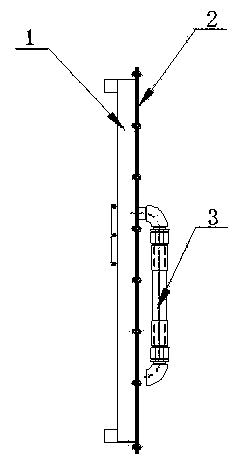

[0020] The present invention includes a gasification bed base 1, a gasification layer 5, a gasification layer pressure plate 2, an air inlet pipe 3 and a gas distribution chamber 4, and is characterized in that the gasification bed base 1 is set as a rectangular groove, and a bolt with a bolt is arranged on the edge of the slot. The connection plate 8 of the hole is provided with a gasification layer 5 covering the notch on the connection plate 8, and a gasification layer pressing plate 2 with bolt holes is provided on the side of the gasification layer 5, and the connection with the gasification bed seat 1 Corresponding to the plates 8, they are connected together with bolts; a rectangular gas distribution chamber 4 with a sealing cover is provided in the middle of one side of the gasif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com