Standard flow type micro wind speed calibration apparatus and calibration method thereof

A standard flow, calibration device technology, applied in measurement devices, speed/acceleration/shock measurement, speed/acceleration/shock measurement equipment testing/calibration, etc. problems, to achieve the effect of saving length, uniform and stable airflow, and accurate measurement data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

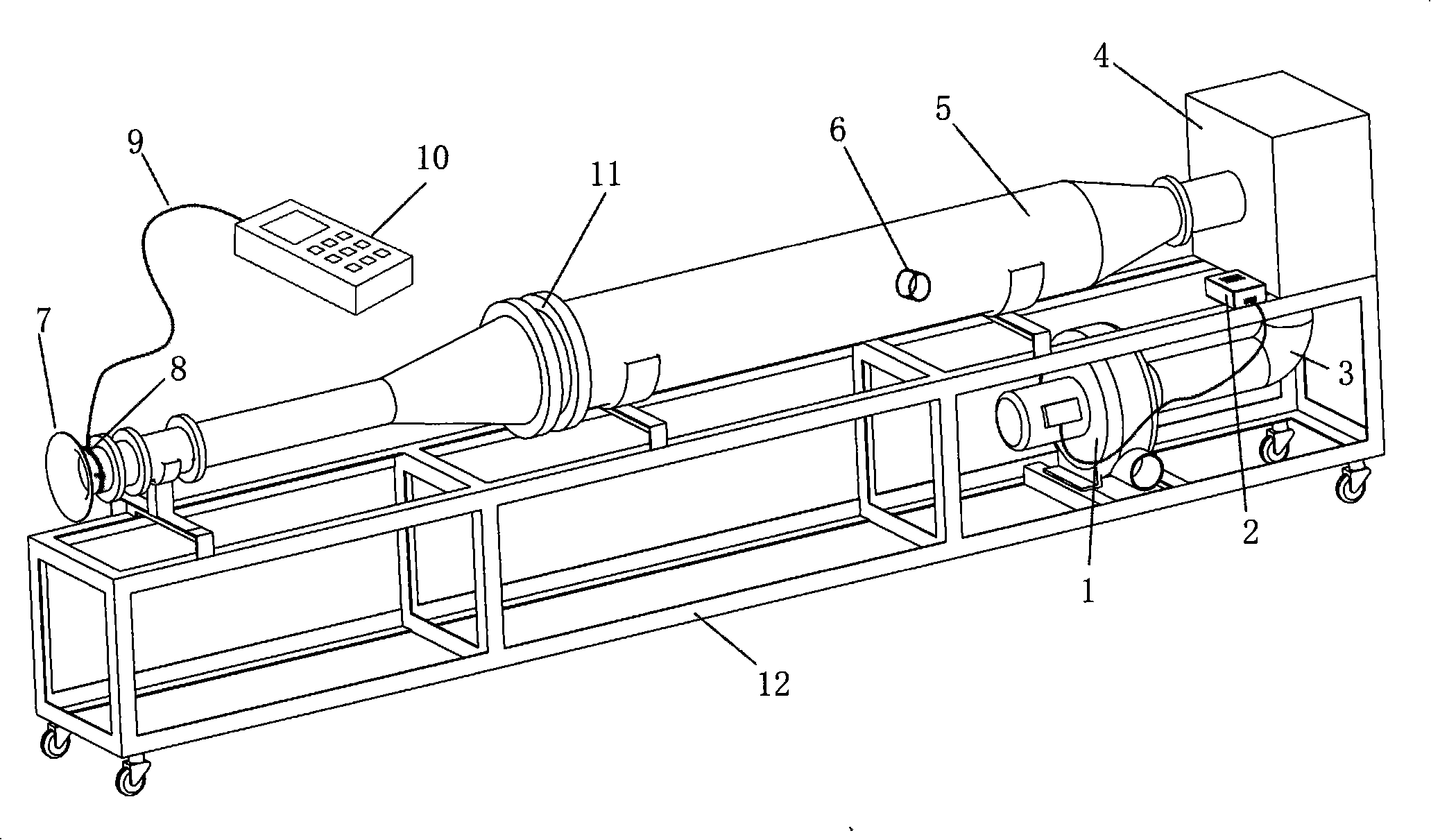

[0029] Standard flow type micro-wind speed calibration device, such as figure 1 shown. The air inlet end is a standard flow tube 7, which is connected to the gradually expanding rectifying air duct 11, the gradually expanding rectifying air duct is connected to the standard air duct 5, and the standard air duct 5 is connected to the static pressure box 4 through a flange; the static pressure box 4 It is connected to the suction port of centrifugal fan 1 through hose 3, and the frequency converter 2 is connected to the motor of centrifugal fan 1 through wires; there is a static pressure collection hole 8 on the standard flow tube, and the static pressure collection hole is connected to the micro pressure difference through rubber tube 9 Meter 10 is connected, and the standard air duct is provided with anemometer measuring hole 6. The frequency converter controls the motor speed and adjusts the air volume of the fan; the standard air duct adopts negative pressure to introduce ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com