Ventilating device for providing a zone of clean air.

a technology of clean air and ventilation device, which is applied in the direction of ventilation details, space heating and ventilation details, domestic heating details, etc., can solve the problems of high noise level, high air velocity, and disturbing effects, and achieves the effect of reducing noise, reducing noise, and reducing nois

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

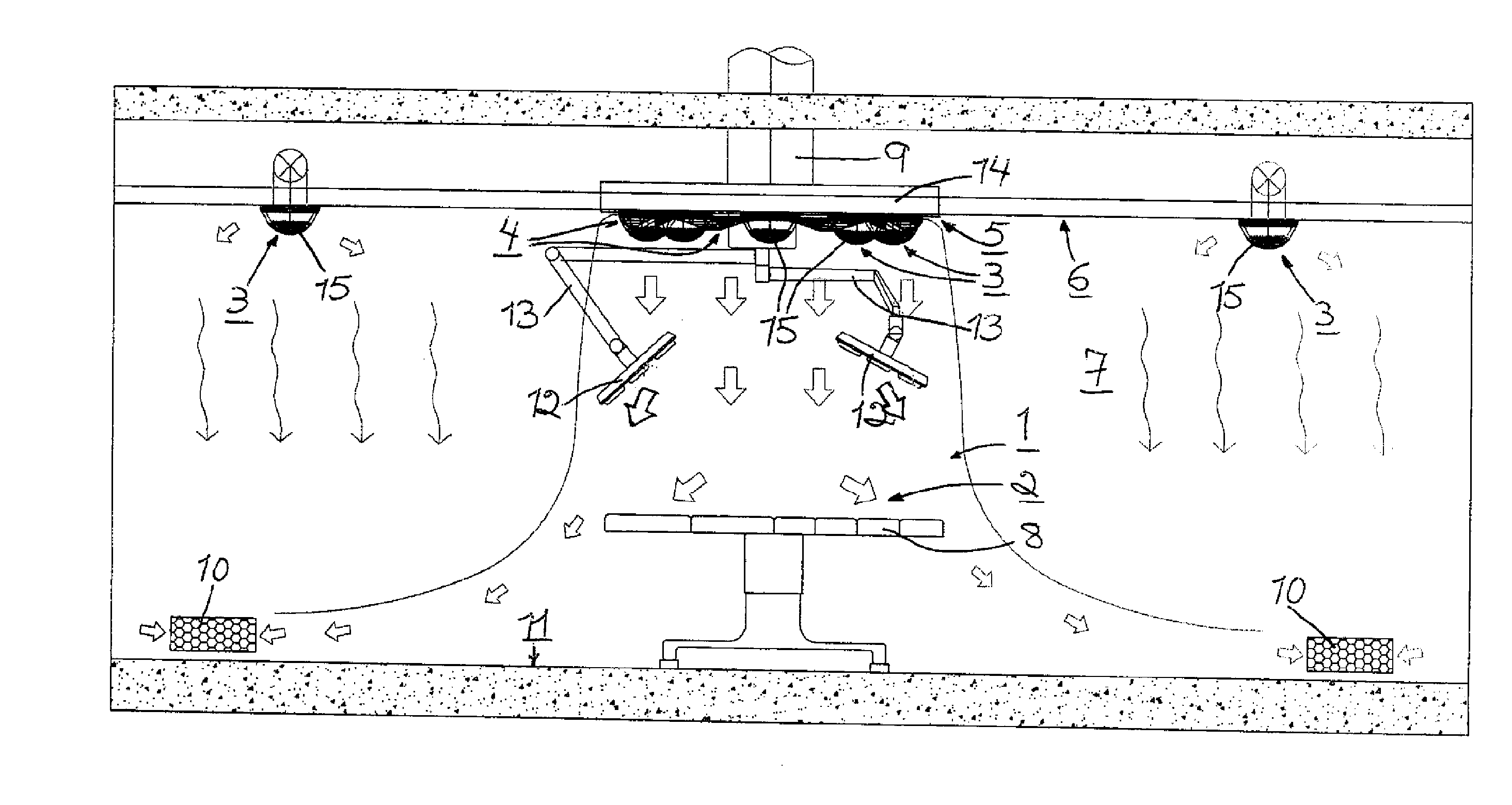

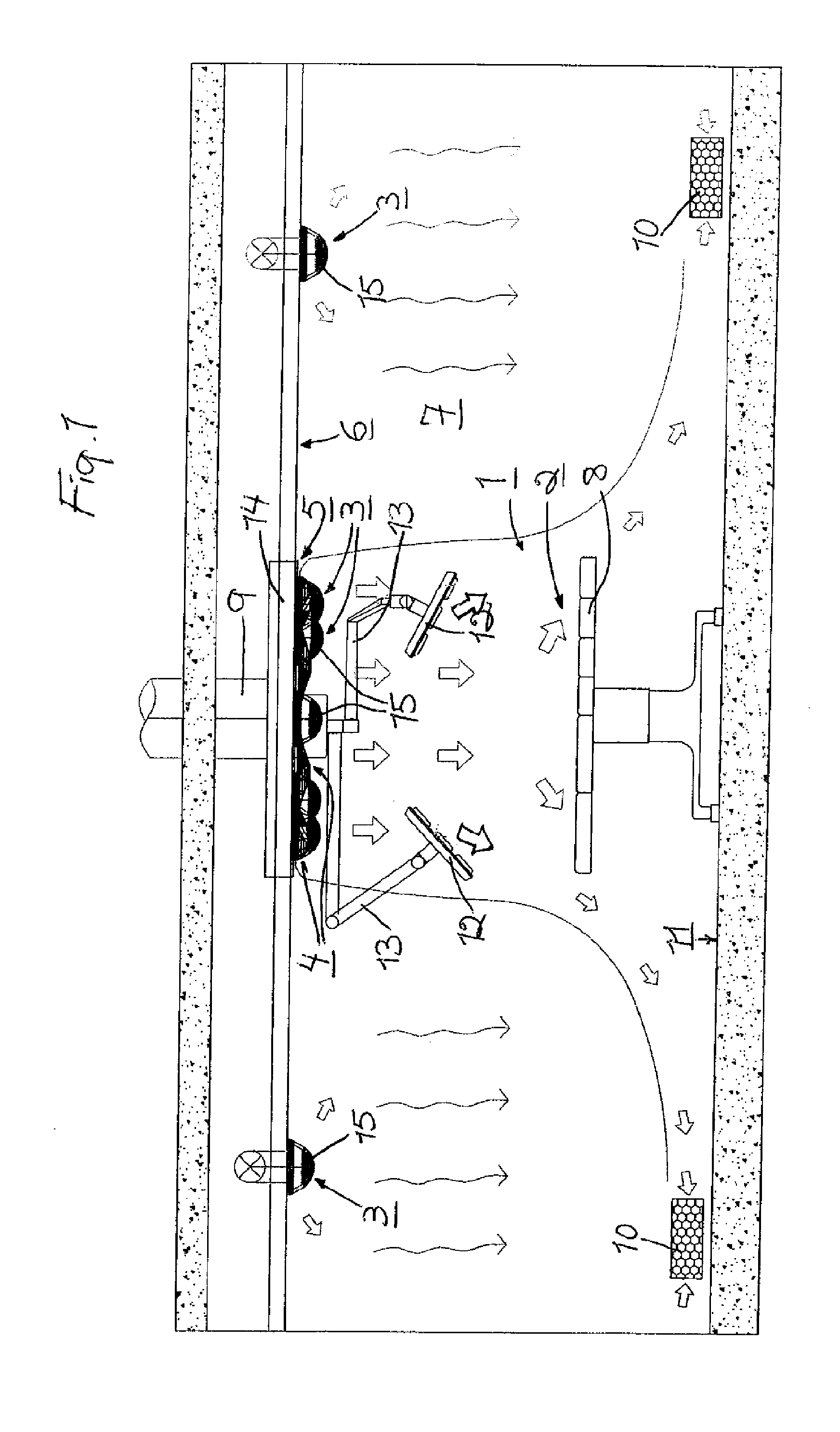

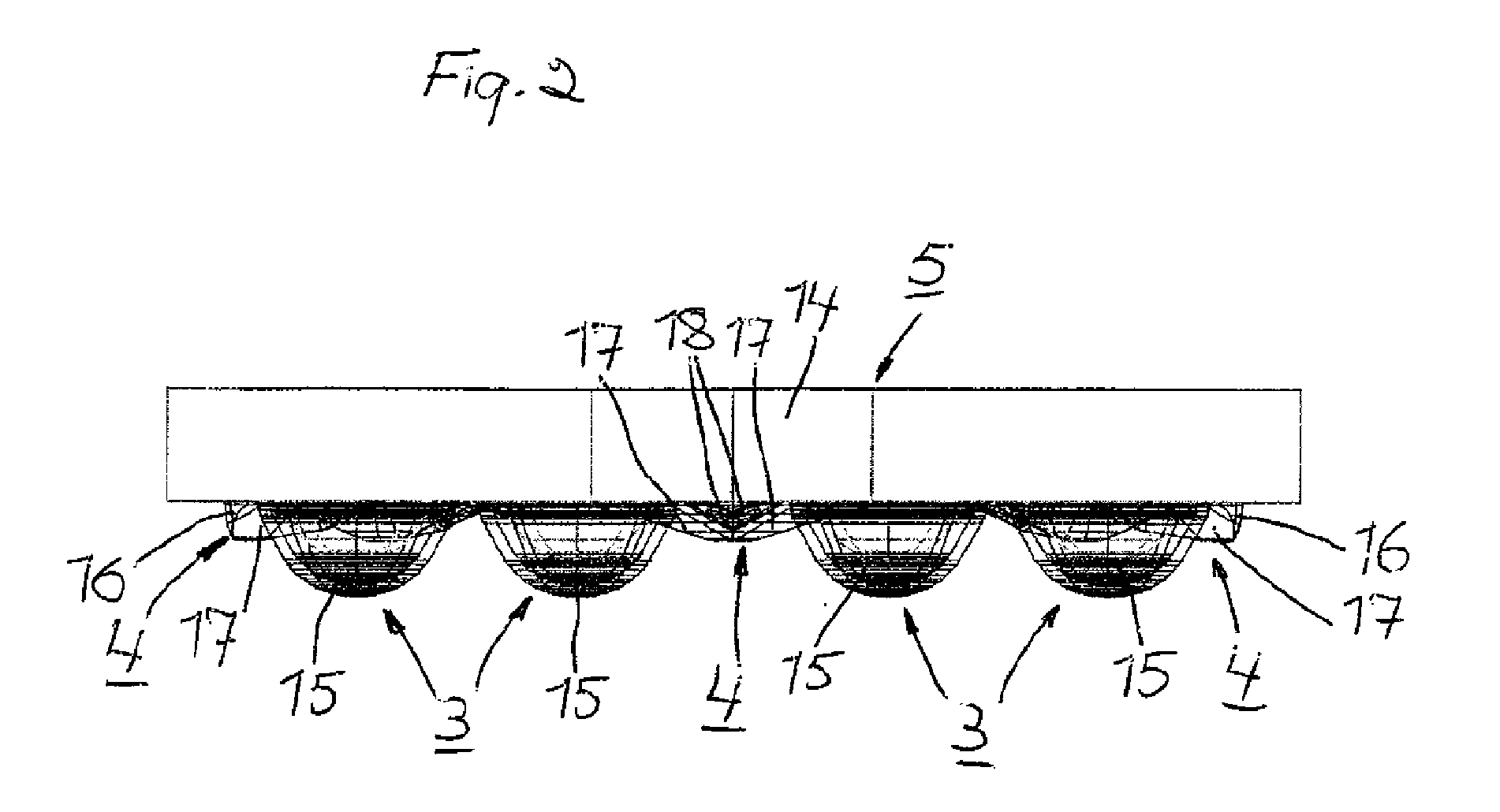

[0014]The ventilating device according to FIG. 1 is intended to create a zone 1 of clean air between the ventilating device and a workplace region, here an operating region 2 in the healthcare sector. The ventilating device comprises air supply units 3 which may be of a conventional type and are adapted to generating laminar air flows intended to constitute said clean air zone 1.

[0015]With the object of achieving, as compared with each individual air supply unit 3, a total air flow with a significantly greater spread which therefore serves a significantly larger region within which personnel have more freedom of movement for their work, the ventilating device according to the invention comprises at least three air supply units 3 disposed in a closed trilateral pattern of three air supply units. The result is that the clean air zone 1 has below the air supply units 3 an extent which in cross-section substantially corresponds to the surface delineated by said closed pattern of air sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com