High-efficiency and low-pollution core engine

A low-pollution, core engine technology, applied in the direction of indirect carbon dioxide emission reduction, combustion methods, lighting and heating equipment, etc., can solve the problems of unfavorable flameless combustion, complex backflow structure, difficult control of backflow flue gas and air mixing process, etc. , to achieve the effect of simple structure, improved thermal efficiency, and fewer parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described below in conjunction with the accompanying drawings, that is, the embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

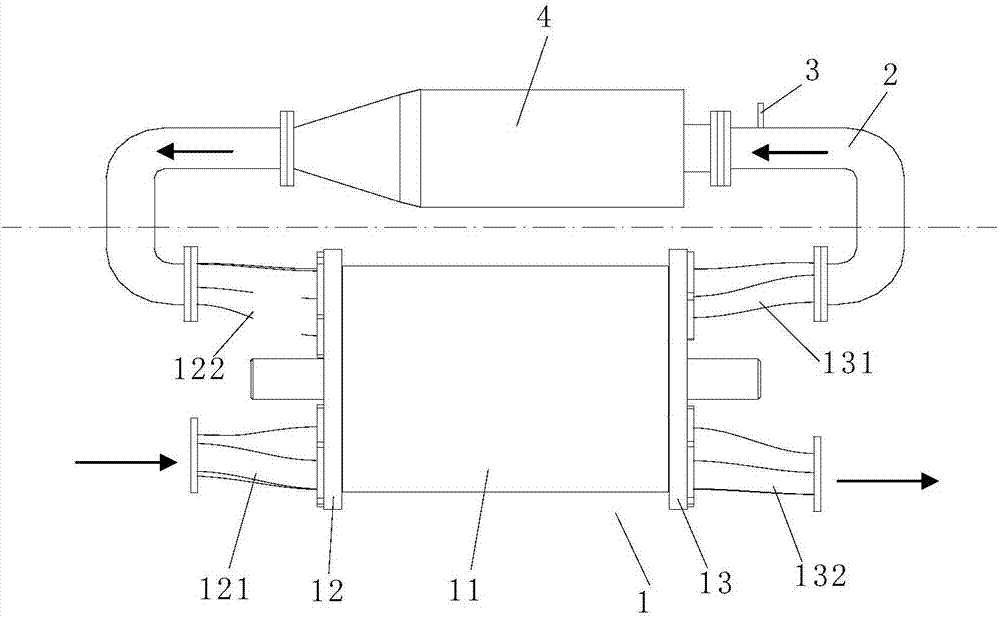

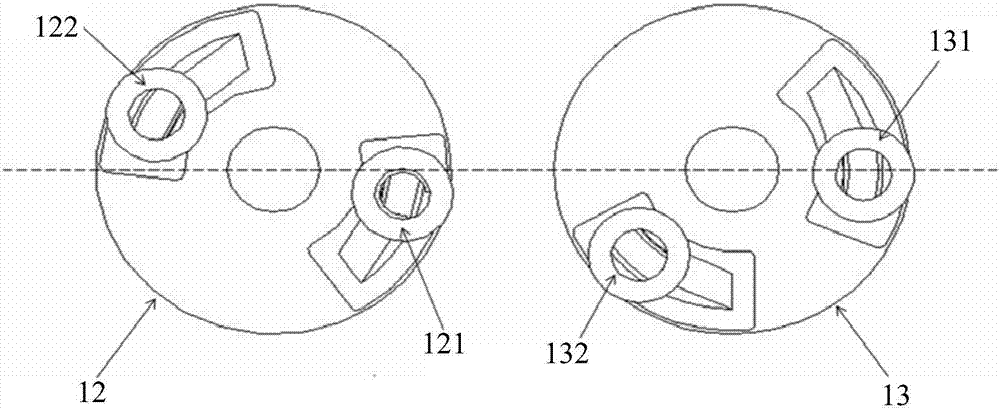

[0024] Such as figure 1 with 2 As shown, the embodiment of the present invention is provided with a wave rotor 1, a pipeline 2, a fuel inlet 3 and a flameless combustion chamber 4; The disk 12 and the outlet port disk 13 are respectively arranged on both sides of the rotor 11; the rotor 11 has a circle of parallel airflow channels, and the inlet port disk 12 is provided with a wave rotor air inlet 121 and a return flue gas inlet 122, The gas outlet plate 13 is provided with a high-temperature and low-oxygen mixed gas outlet 131 and a flue gas outlet 132; the wave rotor air inlet 121, return flue gas inlet 122, high-temperature and low-oxygen mixed gas outlet 131 and flue gas outlet 132 serve as gas The inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com