Engine with compression ratio improving function and engine cylinder group thereof

An engine cylinder and hydraulic cylinder technology, applied in the field of engines and their engine cylinder groups, can solve problems such as difficulty in improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

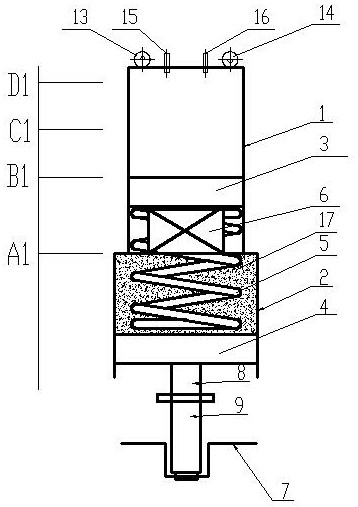

[0041] see figure 1 , this embodiment discloses an engine cylinder group, including a cylinder block 1 and a hydraulic cylinder block 2, the hydraulic cylinder block 2 is located at the lower end of the cylinder block 1, and the head end of the hydraulic cylinder block 2 is connected with the lower end of the cylinder block 1, so that the hydraulic pressure The inner cavity of the cylinder block 2 communicates with the inner cavity of the cylinder block 1, and the hydraulic piston 4 is arranged in the hydraulic cylinder block 2, and the hydraulic piston 4 is in sliding and sealing cooperation with the inner wall of the hydraulic cylinder block 2. An isolation piston 3 is provided, and the isolation piston 3 is in sliding and sealing cooperation with the inner wall of the cylinder body 1. A certain amount of liquid 17 is filled between the isolation piston 3 and the hydraulic piston 4 (the amount of liquid to be filled is determined according to the actual situation, generally n...

Embodiment 2

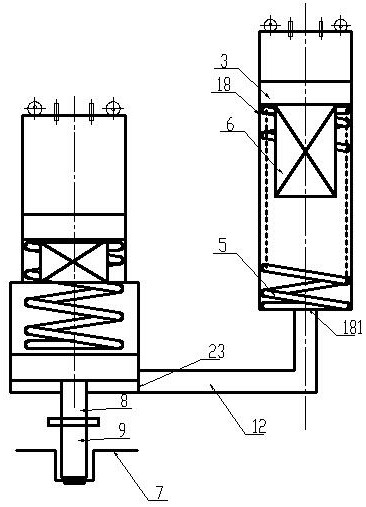

[0057] see Figure 4, this embodiment discloses an engine cylinder group, including a cylinder block 1 and a hydraulic cylinder block 2, an extension part is added to the cylinder block 1, the hydraulic cylinder block 2 is arranged laterally at the lower end side of the cylinder block 1, and the head of the hydraulic cylinder block 2 The end communicates with the side wall of the cylinder block 1, the hydraulic cylinder block 2 is provided with a hydraulic piston 4, and the hydraulic piston 4 is in sliding and sealing cooperation with the inner wall of the hydraulic cylinder block 2, and the cylinder block 1 is provided with an isolation piston 3 , the isolation piston 3 is in sliding and sealing cooperation with the inner wall of the cylinder block 1, the bottom of the cylinder block 1 is sealed, and a certain amount of liquid 17 is filled between the isolation piston 3 and the hydraulic piston 4, (the liquid filled in is determined according to the actual situation Generally...

Embodiment 3

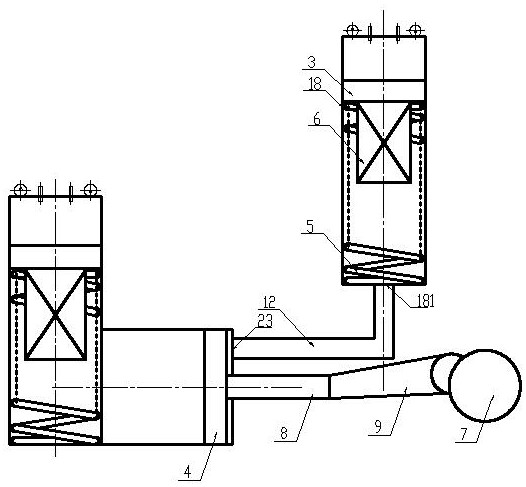

[0068] see figure 1 , the present embodiment discloses an engine with improved compression ratio, comprising at least one engine cylinder group as described in Embodiment 1, the hydraulic cylinder block 2 tail ends of each engine cylinder group are open, and the hydraulic pistons 4 of each engine cylinder group Connect with the crankshaft 7 in the crankshaft 7 case by connecting rod 9. Of course, it is also possible to connect the hydraulic piston 4 to the piston rod 8 and connect the piston rod 8 to the connecting rod 9. The hinged connection between the piston rod 8 and the connecting rod 9 can be the same as the original piston and the connecting rod 9. Certainly, It can be adjusted according to actual needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com