Planing and transporting beam structure and machine group type coal mining unit

A technology of coal mining unit and beam structure, which is applied in the directions of earthwork drilling, slitting machinery, propulsion, etc., can solve the problems of limited coal mining cutting capacity, personnel hazards on the working face, and high risk of chain breakage, so as to improve the mining efficiency. The effect of coal cutting capability, ease of maintenance, and reduced chance of chain breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be described below in conjunction with examples, as will be described, as described in Examples of the present invention, not all of the embodiments of the invention. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

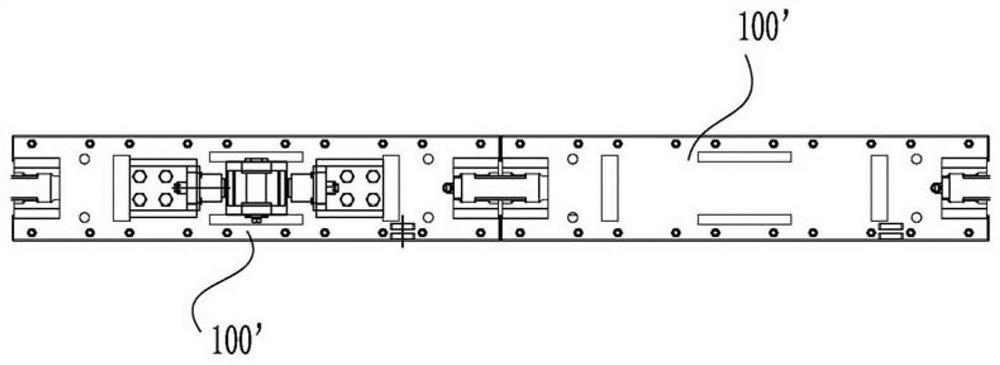

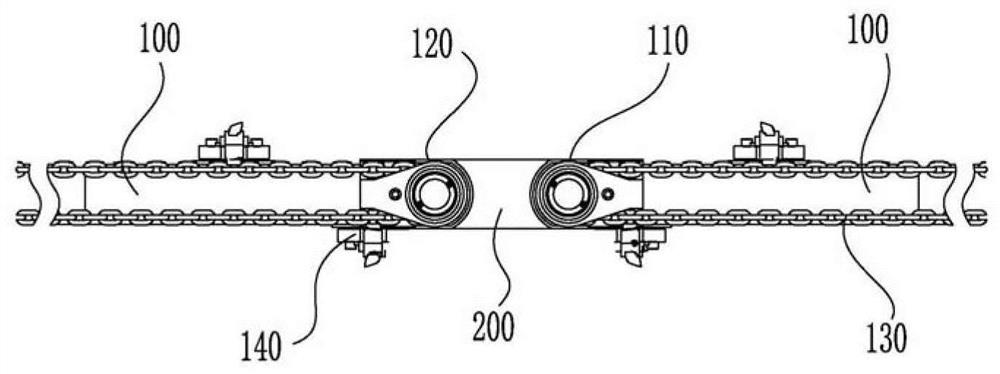

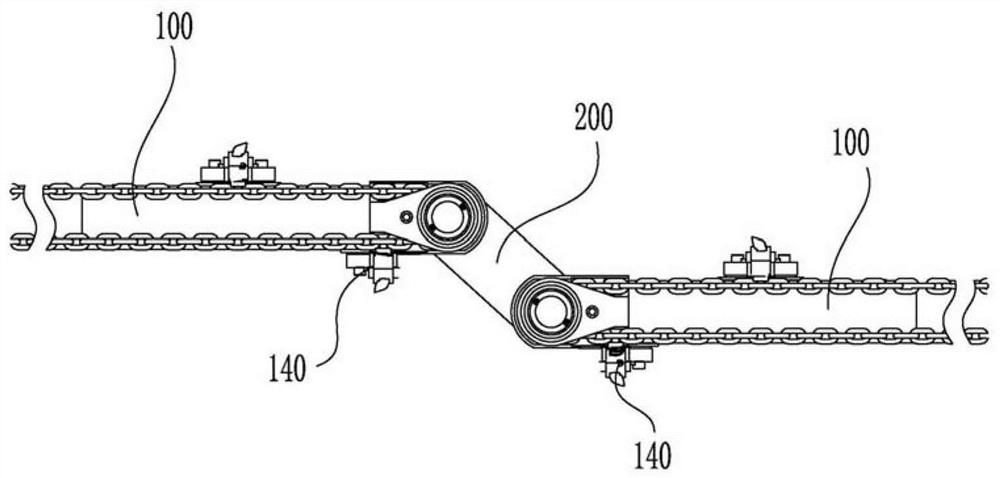

[0036] like Figures 2 to 4 As shown, the planing beam structure provided in this embodiment includes a planing beam body 10, and a plurality of coal-coated units are provided on the planing beam body 10, each coal-containing unit including a first sprocket 110, a second sprocket 120 and chain 130 for connecting the first sprocket 110 and the second sprocket 120, and a plurality of planer 140 is disposed intervals.

[0037] The planing beam structure provided in this embodiment, by providing a plurality of coal coal units on the planing beam body 10, each coal unit includes a first sprocket 110 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com