A crank connecting rod mechanism piston reciprocating single-cylinder internal combustion engine

A crank connecting rod mechanism, internal combustion engine technology, applied in the direction of internal combustion piston engines, machines/engines, mechanical equipment, etc., can solve the problems of instantaneous response lag, high supercharging degree, engine can not adapt to cooling technical scheme and supercharging technical scheme, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

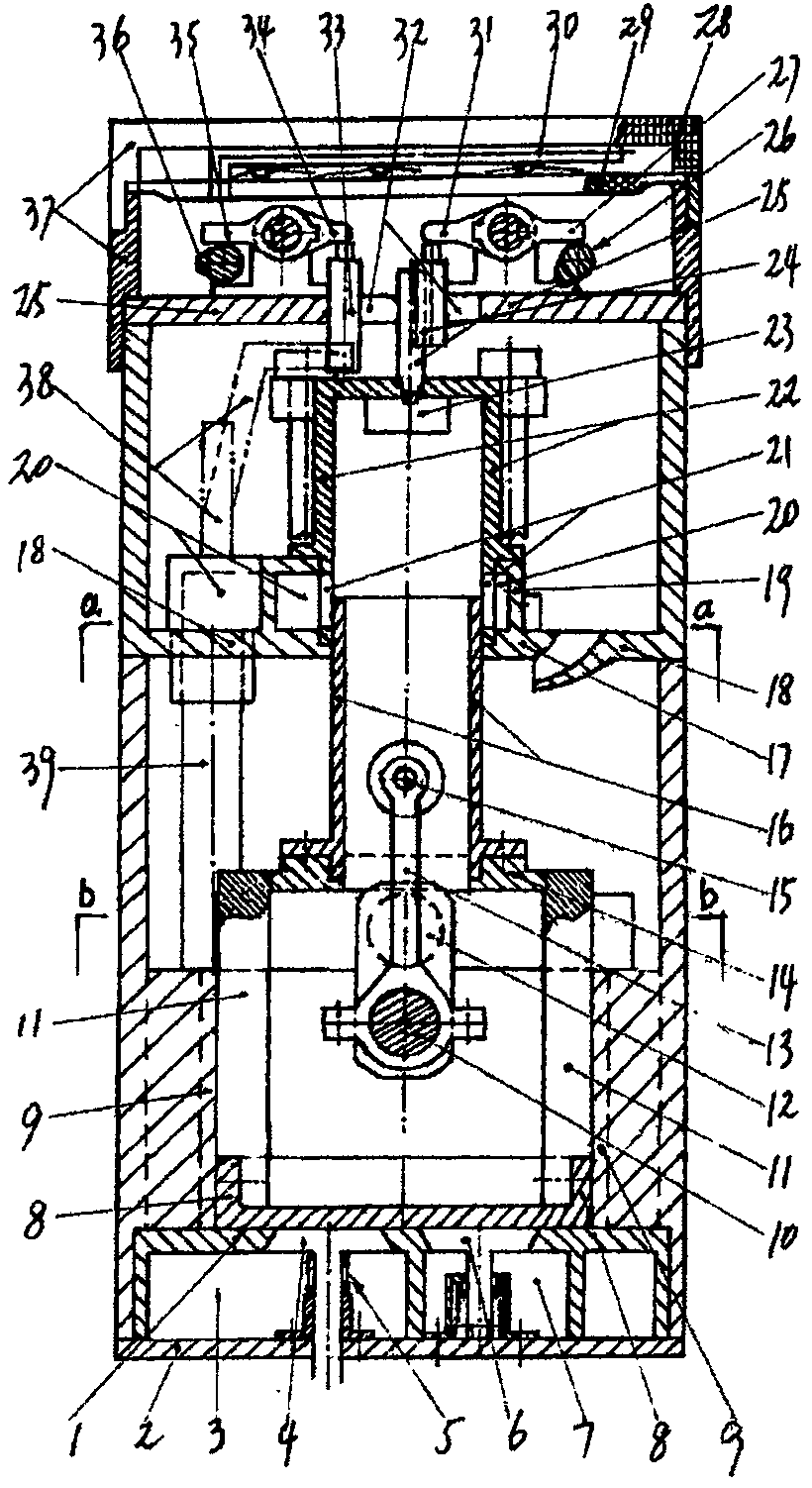

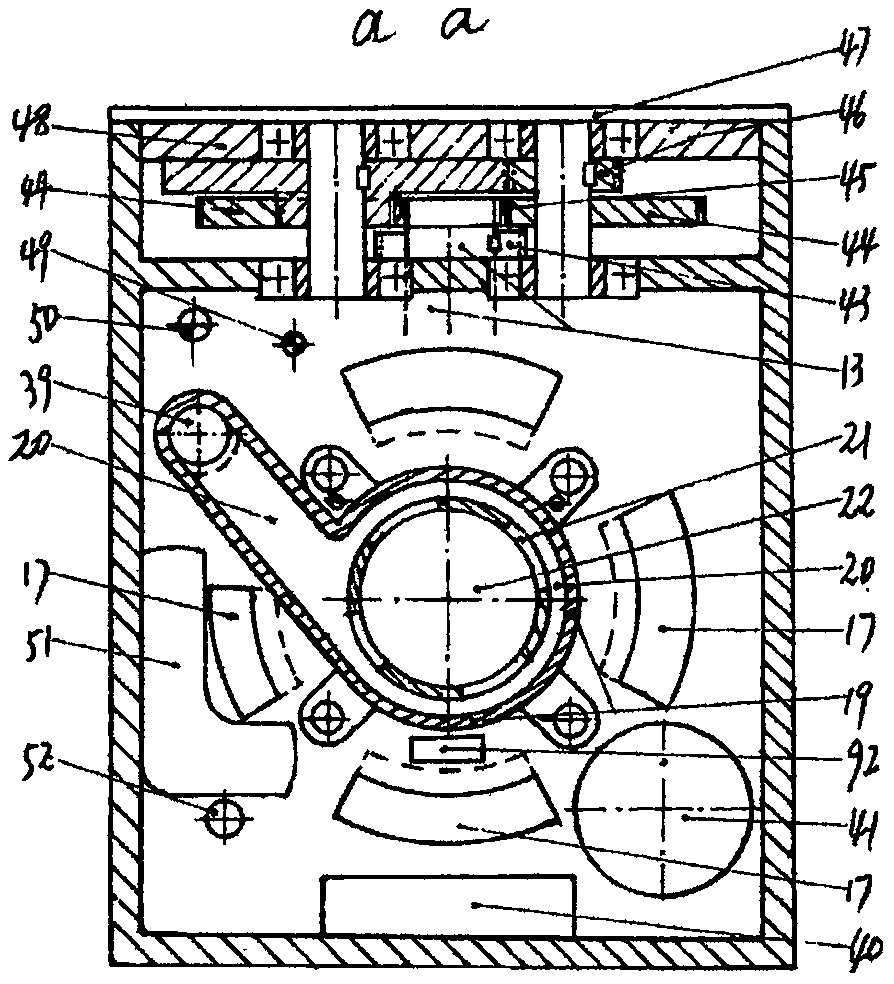

[0094] figure 1 combine Figure 5 Shown: the engine body is divided into upper and lower parts by the body diaphragm 18 and connected. The integrated control system is arranged on the top cover plate 25 of the engine. The energy recovery system is located at the rear of the engine.

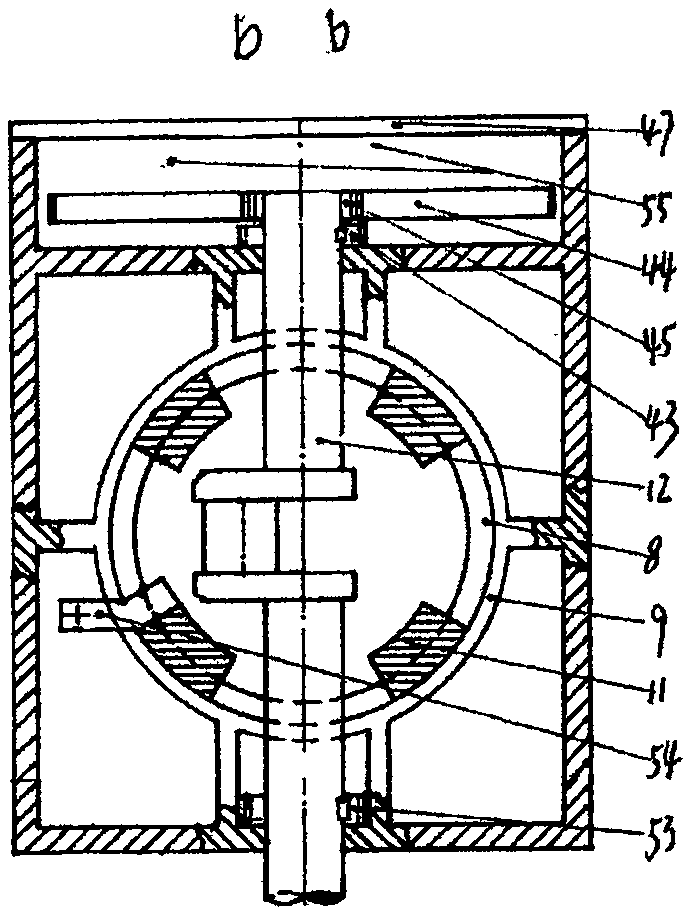

[0095] figure 1 , 3 , 5 shows: the supercharging mechanism is combined with the power mechanism, and is arranged in the middle of the lower part of the body. The supercharging mechanism frame is formed by connecting the upper and lower ends of the frame with frame columns 11. The upper end 14 of the supercharging frame is connected with the piston 16 of the engine cylinder, and the lower end Connect or directly make the booster cylinder piston 8; the booster cylinder piston diameter ≥ 2 times the engine cylinder piston diameter, the crank connecting rod mechanism is arranged in the booster frame, the small end of the connecting rod 14 is connected with the engine cylinder piston pin 15, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com