Method for preparing syndiotactic poly1,2-butadiene thermoplastic elastomer

A thermoplastic elastomer, butadiene technology, applied in the field of syndiotactic polymerization, can solve problems such as peroxide vulcanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

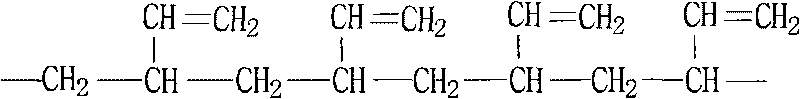

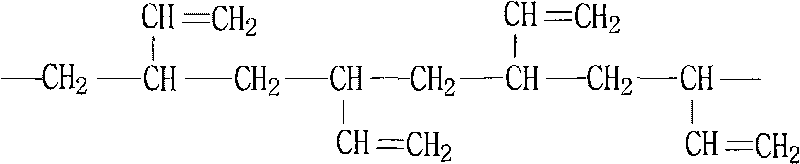

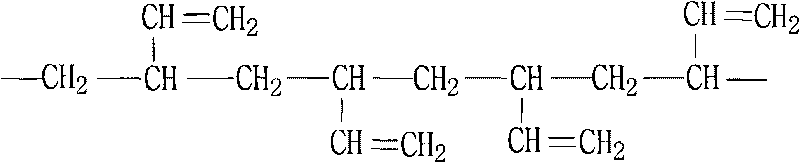

Image

Examples

Embodiment 1~6

[0033]The synthetic rubber added in embodiment 1 and 6 is Buna-CB24 neodymium system butadiene rubber, and the added amount is 0.3g, 75g; the added synthetic rubber in embodiment 2, 3 is high vinyl polybutadiene rubber, and the added amount is 5g . Other conditions are as follows: Add dry synthetic rubber into a 5L stainless steel kettle, replace the reactor with nitrogen with a purity of 99.99% for 5 times, then add 2500ml of dry hexane solvent oil, start stirring and heat up to 90°C, wait for the added After the micelle is completely converted into a uniform glue solution (about 24 hours), the temperature of the reactor is lowered to room temperature, and 455ml (300g) of 1,3-butadiene monomer is added thereto, and the temperature is raised to 70° C. of polymerization initiation temperature, and then Add 0.56mmol of iron isooctanoate, (3.00mmol of triisobutylaluminum+7.00mmol of triethylaluminum) and 1.67mmol of diethyl phosphite in sequence, and at the same time, use N 2 Ma...

Embodiment 7~12

[0038] In Examples 7 to 9, the order of catalyst addition is iron isooctanoate, diethyl phosphite, (triisobutylaluminum+triethylaluminum); triisobutylaluminum, iron isooctanoate, triethylaluminum, Diethyl phosphite; Triethylaluminum, iron isooctanoate, triisobutylaluminum, diethyl phosphite, other conditions are the same as in Example 4, and the main properties are shown in Table 3.

[0039] In Examples 10 to 12, the amount of catalyst added is 0.56 mmol of iron naphthenate, (2.00 mmol of triisobutylaluminum+8.00 mmol of triethylaluminum), 1.67 mmol of diethyl phosphite; 0.56 mmol of iron isooctanoate, ( Triisobutylaluminum 3.00mmol+triethylaluminum 7.00mmol), diethyl phosphite 2.24mmol; iron isooctanoate 0.56mmol, (triisobutylaluminum 5.00mmol+triethylaluminum 5.00mmol), diethyl phosphite 1.67mmol, other conditions are the same as in Example 4, and the main properties are shown in Table 3.

[0040] table 3

[0041]

[0042]

Embodiment 13

[0044] The amount of catalyst added is 0.84mmol of iron isooctanoate, 2.50mmol of diethyl phosphite, (7.50mmol of triisobutylaluminum+17.50mmol of triethylaluminum), and other conditions are the same as in Example 6. The obtained polymer was rubber with a yield of 85% and no crystalline melting peak.

PUM

| Property | Measurement | Unit |

|---|---|---|

| 300% modulus stress | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com