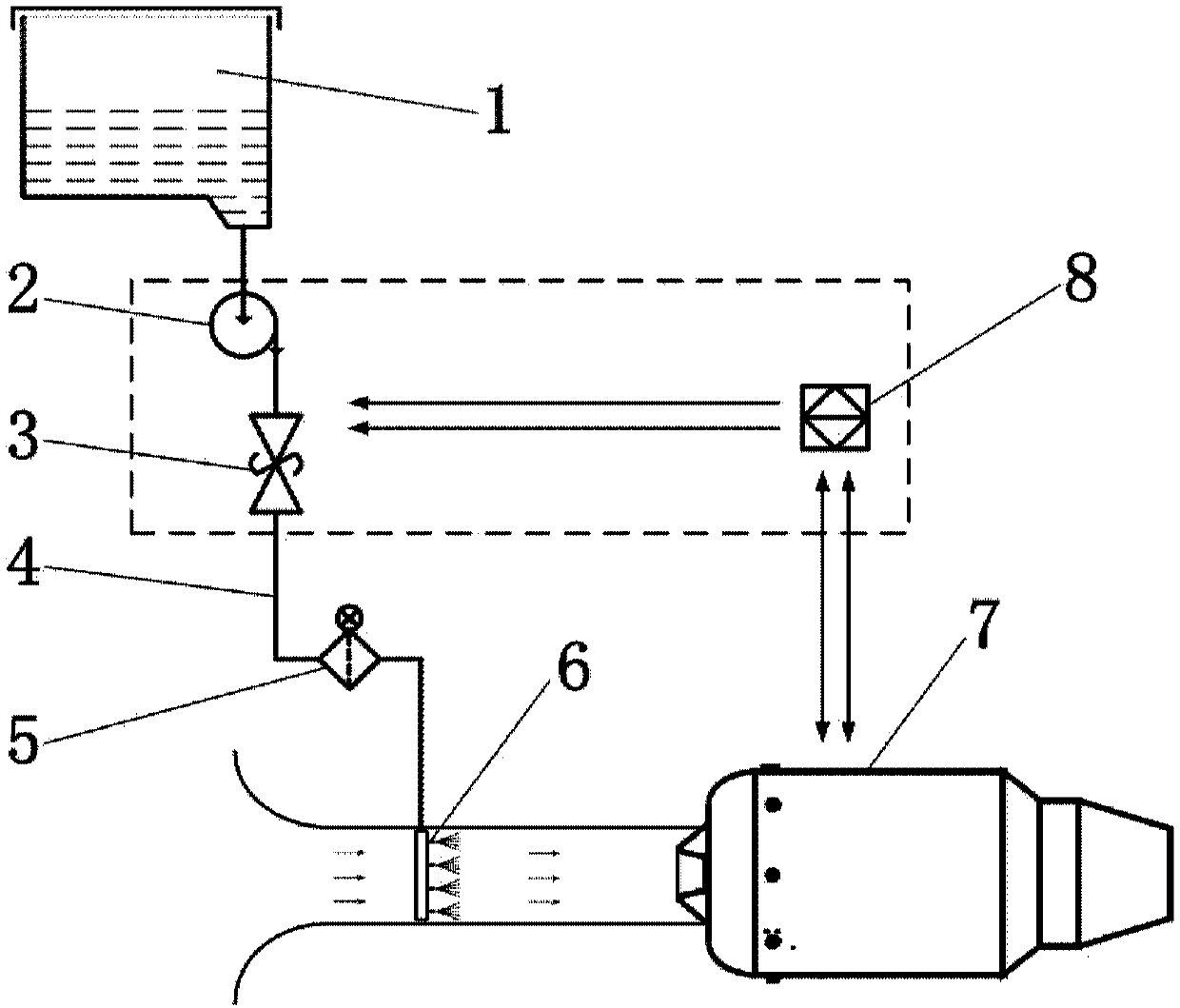

Water or methyl alcohol spraying thrust increasing system suitable for small turbojet engine

An engine and methanol technology, applied in the aviation field, can solve the problems of increased engine cost, complex system structure, and increased weight, and achieve the effects of no power consumption, low technical difficulty, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the examples, the following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0039] A turbojet engine according to the invention comprising:

[0040] an air intake duct through which air enters said turbojet engine;

[0041] an air compressor arranged after the air inlet to increase the pressure of the air entering through the air inlet;

[0042] Combustion chamber, after the air passes through the compressor, it enters the combustion chamber to be mixed with fuel for combustion, and expands to perform work;

[0043] a turbine, the turbine is coaxially installed on the engine shaft with the compressor, and the high-temperature and high-pressure gas flowing out of the combustion chamber drives the turbine to rotate; and

[0044] The tail nozzle, in which the high-temperature and high-pressure gas flowing out of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com