Design method of adjustable nozzle blade of megawatt radial turbine expander

A technology of turboexpander and nozzle blades, which is applied in mechanical equipment, engine components, machines/engines, etc., and can solve problems such as nozzle blade design, impeller high-cycle fatigue, and nozzle outlet airflow unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

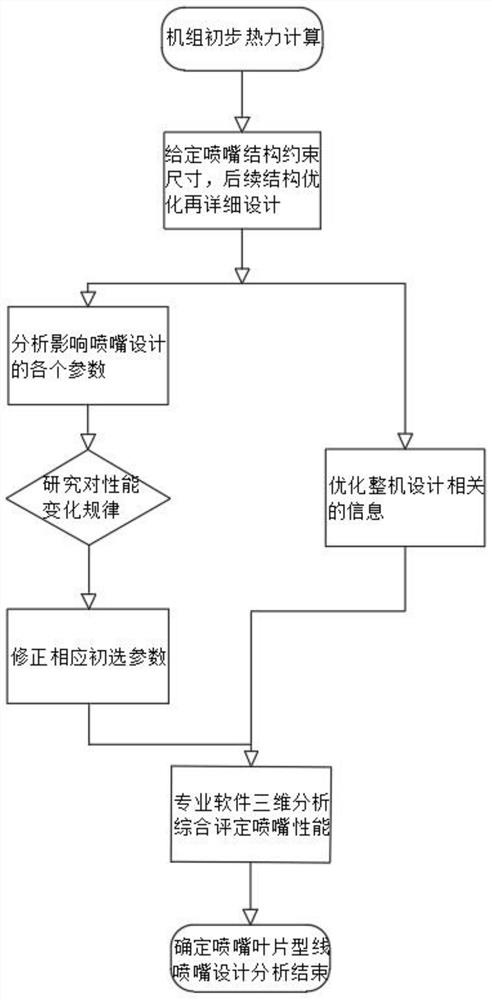

[0043] Specific implementation mode one: combine Figure 1-Figure 10 Describe this embodiment, the design method of the adjustable nozzle vane of a kind of megawatt class radial turbo expander of this embodiment, comprises the following steps:

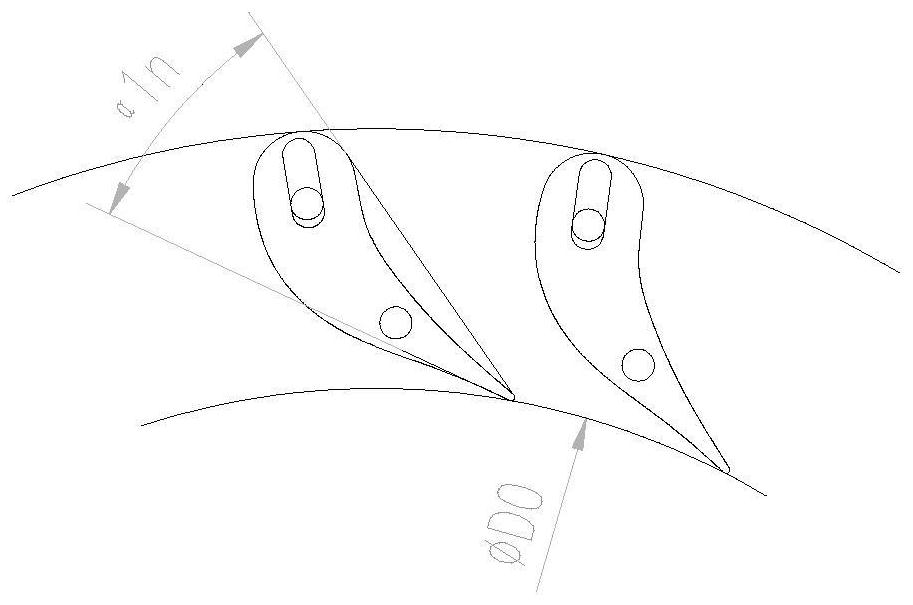

[0044] Step 1: Determine the parameters of the preliminary nozzle. In the one-dimensional design, the nozzle design usually adopts empirical design. The main reason is that in the three-dimensional geometric modeling, the chord length and angle distribution of the nozzle blade will directly affect its radial length distribution. For impeller design, usually due to mutual constraints in structural design, the size of the nozzle will be adjusted for preliminary design, and the parameters of the nozzle will be initially fixed. The chord length of the nozzle blade 2 / the pitch of the nozzle outlet is b / l 1n =1.8, Nozzle blade 2 number Z N =21, as shown in Table 1;

[0045] Table 1 Comparison table of main parameters of aerodynamic structu...

specific Embodiment approach 2

[0061] Specific implementation mode two: combination Figure 7 Describe this embodiment, a device and method for obtaining the best imaging parameters of the bearing cylindrical roller cylinder in this embodiment, complete the following three-dimensional design in professional design software, based on the relevant design criteria of the nozzle, select the nozzle blade 2 In the airfoil selection, focus on large-thickness inlet and better aerodynamic performance, combined with market research, and the design requirements of the main engine mechanism, this plan uses a certain airfoil as the basis for nozzle airfoil design, and the inlet section of nozzle blade 2 is R15. 77, which is advantageous from an aerodynamic point of view.

specific Embodiment approach 3

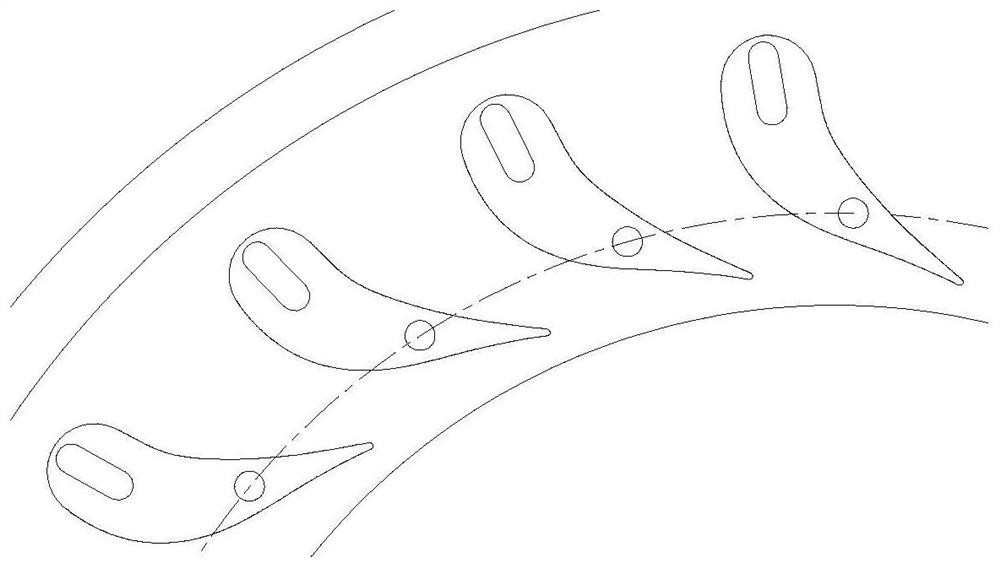

[0062] Specific implementation mode three: combination Figure 4-Figure 5 This embodiment is described, which is a design method for adjustable nozzle blades of a megawatt radial turboexpander. After the nozzle blade type is selected, the rationality of its flow field directly determines the impact on the performance of the whole machine. Focus on two points in the flow field analysis: ① The separation of the flow field should be as small as possible; ② The acceleration state should be ensured in the cascade channel; Except for the small flow separation loss and wake loss in the outlet section of the suction surface, there is no other loss in the entire flow field; from the absolute Mach number distribution cloud diagram of the flow field, we can see that in the cascade channel, the velocity distribution level is obvious, The flow in the entire channel presents a state of obvious acceleration, and there is no channel expansion; therefore, from the above analysis, it can be see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com