Throat deviating type pneumatic thrust vectoring nozzle with fuel supplementing and thrust augmenting functions and control method

A vector nozzle and control method technology, applied in the direction of machines/engines, jet propulsion devices, etc., can solve the problem of having no nozzles with both aerodynamic thrust vectoring technology and afterburning afterburning technology, so as to ensure performance and reduce structural weight , The effect of improving fuel efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

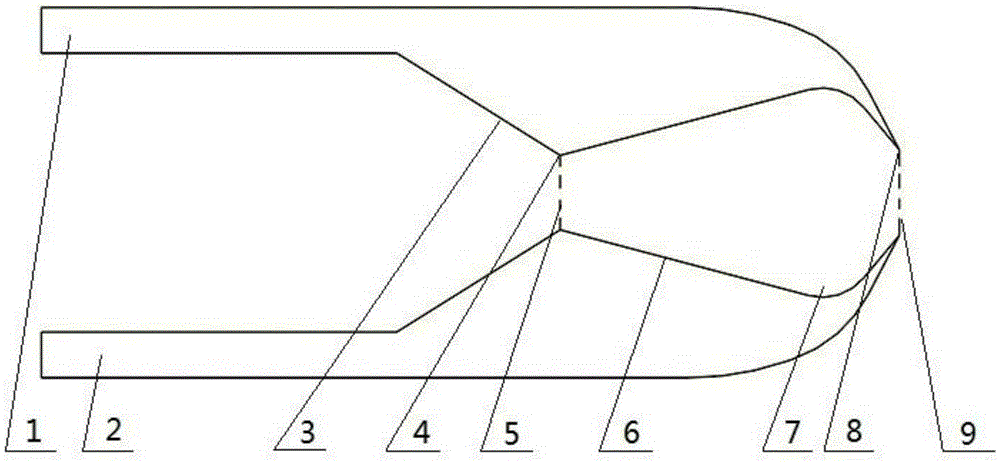

[0025] figure 1 The structure diagram of the conventional throat offset type aerodynamic vectoring nozzle shown is mainly composed of a nozzle upper wall surface 1, a nozzle lower wall surface 2, a throat front convergent section 3, a throat sharp point 4, a The throat 5, the expansion and convergence section 6 at the front of the second throat, the rear body cavity 7, the sharp point 8 of the second throat, and the second throat 9 are composed of components.

[0026] In the present invention, on the basis of maintaining the same internal profile of the above-mentioned conventional throat offset type aerodynamic vectoring nozzle, by injecting fuel oil near a throat 5, the total temperature and total pressure of the main flow are increased, and mass is added to the main flow, thereby The adjustment and control of the vector angle of the nozzle is realized, and the afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com