Negative-pressure injection type full-premix sectional combustion heating device

A heating device and staged combustion technology, applied in the burner, combustion method, combustion type, etc., can solve the problem of high total investment and cost of gas heating system, small adjustment range of heating load ratio, and penetration of combustion products. indoor and other problems, to achieve the effect of breaking through technological monopoly, compact structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In the following, a negative pressure jet type fully premixed segmented combustion heating device of the present invention will be described in further detail in conjunction with specific embodiments.

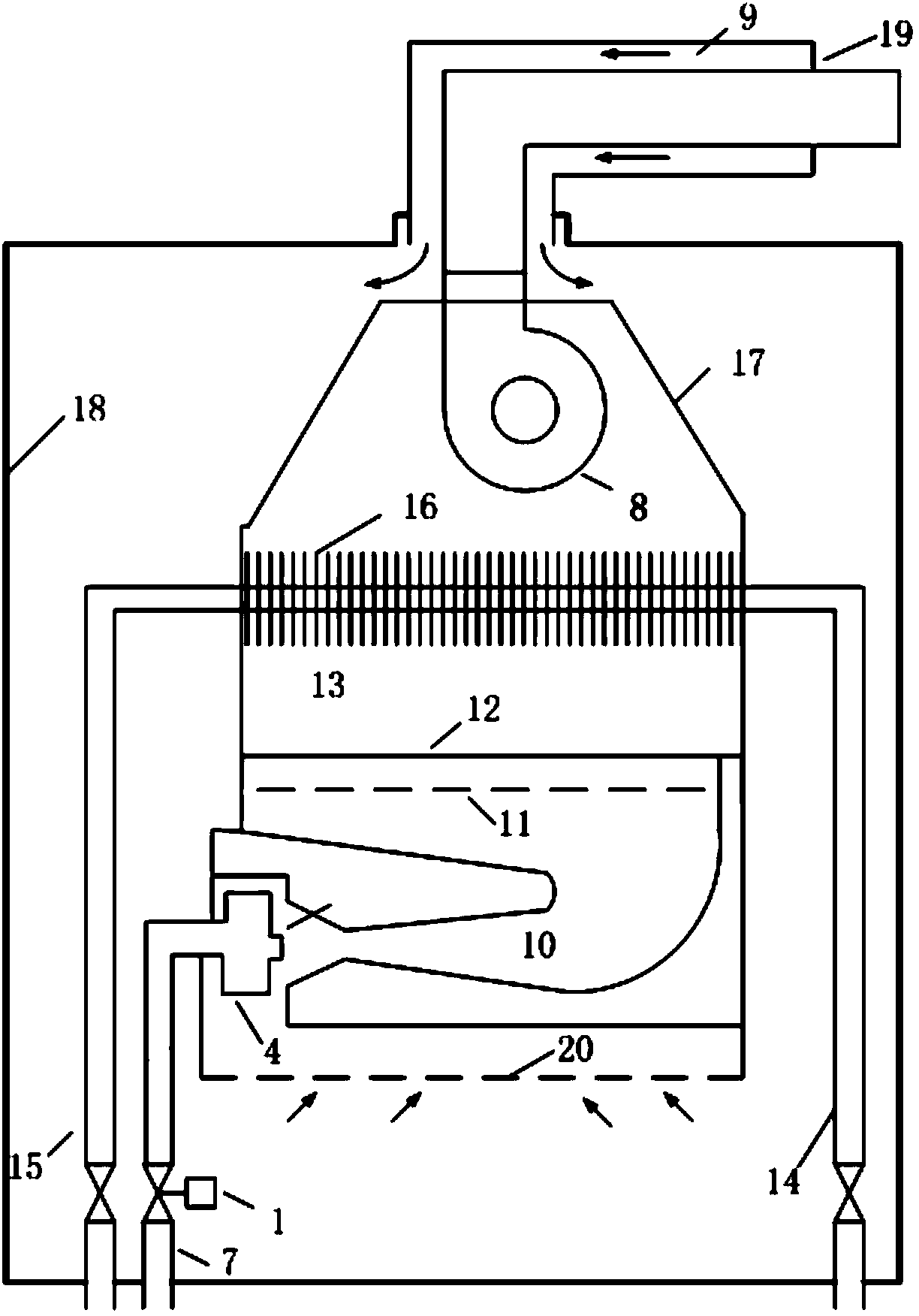

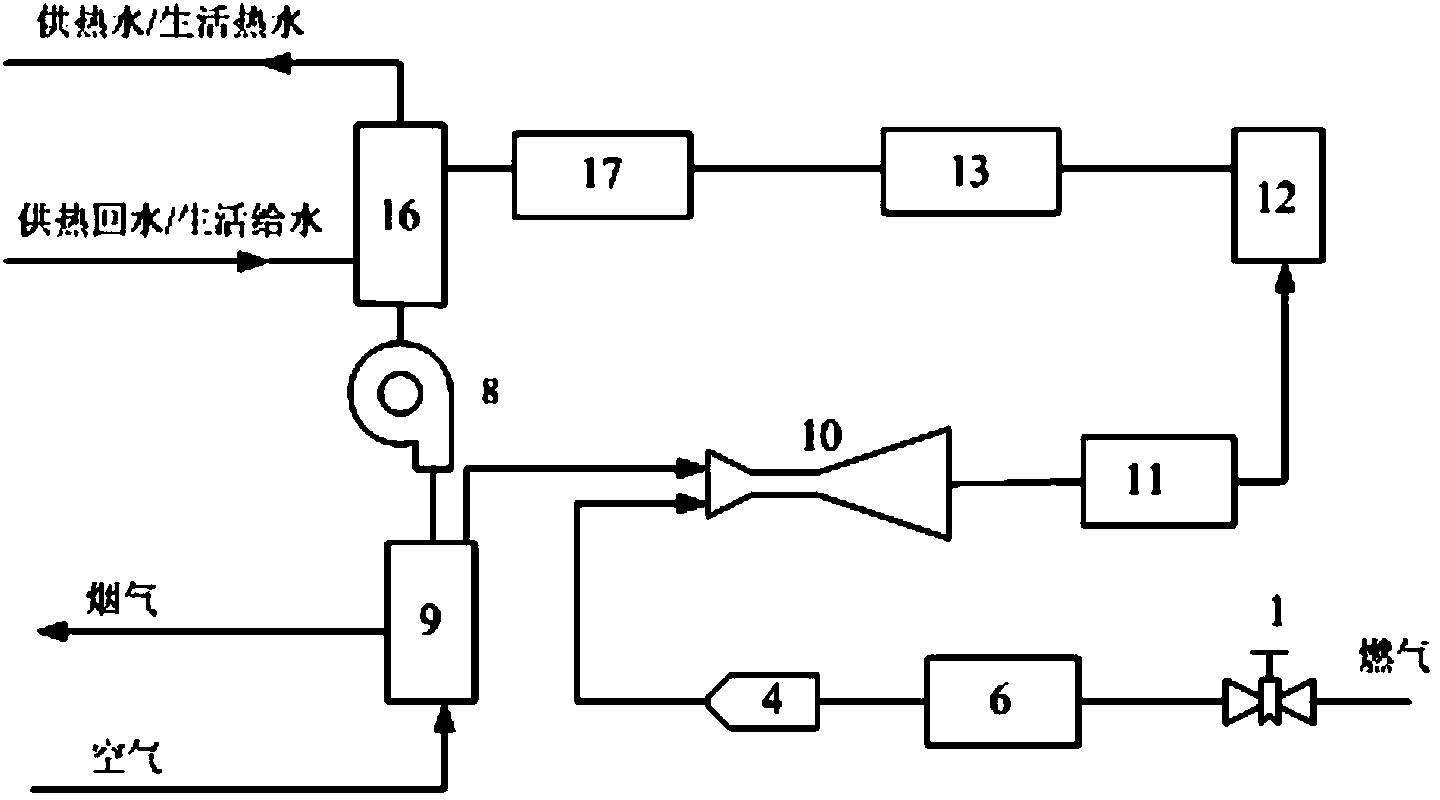

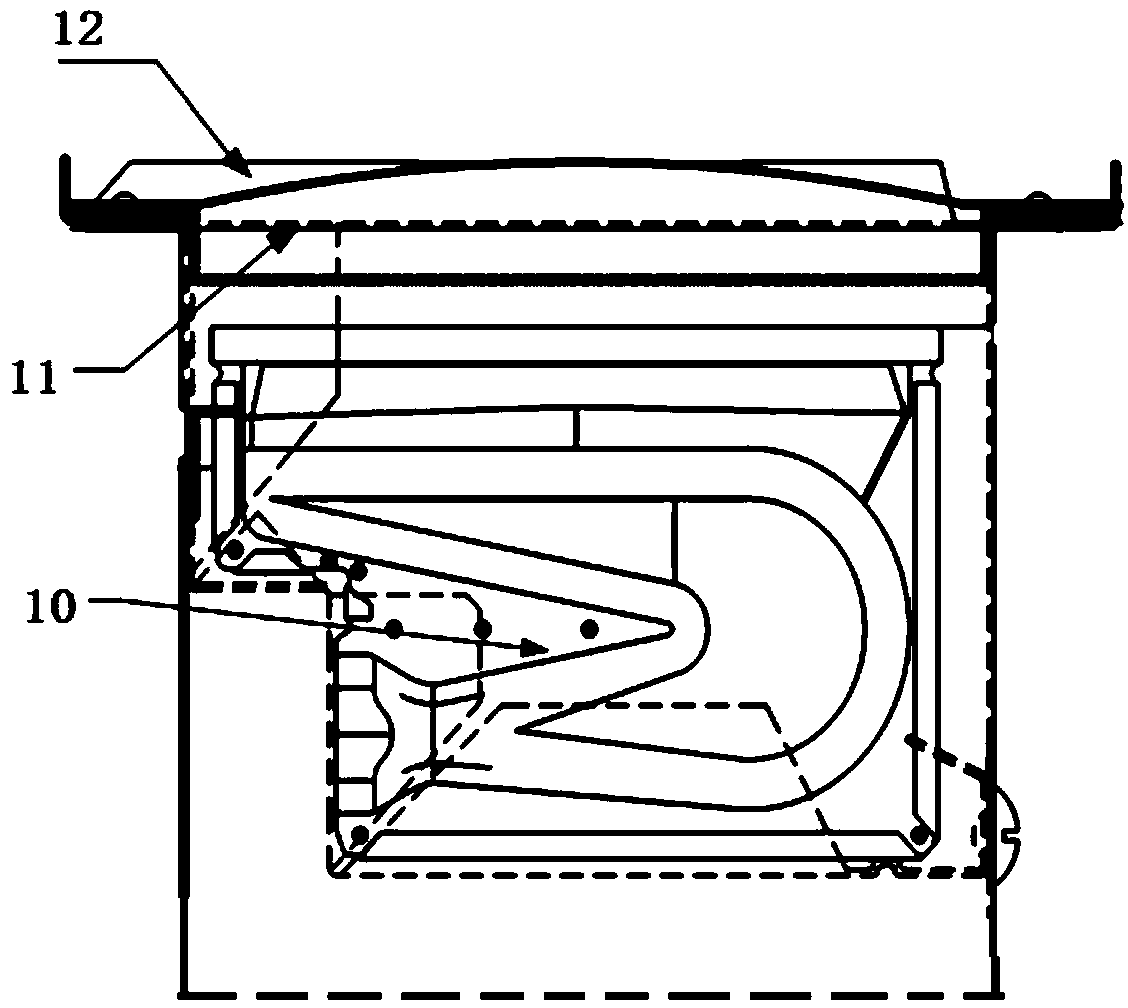

[0019] Such as figure 1 As shown, a negative pressure jet type fully premixed segmented combustion heating device of the present invention includes a shell 18, a fuel segmented supply system, a combustion chamber 13, a heat exchange system and an induced air exhaust system.

[0020] The fuel segmented supply system includes a gas pipe 7 and a gas distribution cavity 5 connected to it. The gas distribution cavity 5 is also provided with a solenoid valve A1 and a solenoid valve B2. The solenoid valve A1 and the solenoid valve B2 are respectively above An air inlet cavity 6 is provided, and a group of gas nozzles 4 are respectively arranged on the air inlet cavity 6, each group of gas nozzles 4 includes a plurality of gas nozzles 4, the diameter of the gas nozzle 4 is 1.2 ~ 2.5mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com