Precise baking device for steel ladles

A baking device and ladle technology, applied in the configuration of indicating equipment/measuring equipment, casting melt containers, manufacturing tools, etc., to achieve improved control, reduce gas consumption, and prevent clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

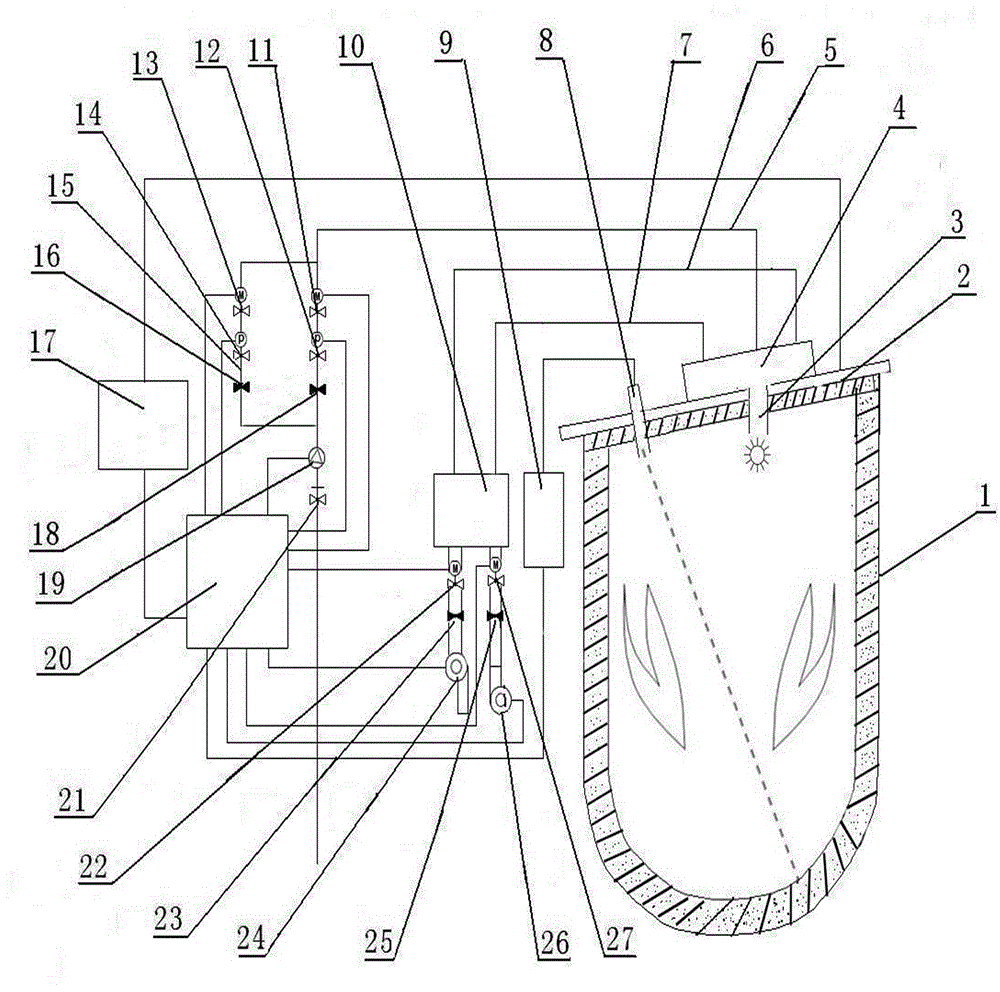

[0020] like figure 1 As shown, a ladle precision baking device, the structure includes: a ladle 1 and a ladle cover 2, a self-preheating burner 3, a gas supply system, an air supply system, a temperature detection system and a control cabinet 20, a gas supply system and an air The supply system is commonly connected to the self-preheating burner 3;

[0021] The temperature detection system includes an infrared thermometer 9, an infrared probe 8, the infrared probe 8 is embedded in the ladle cover 2, the infrared thermometer 9 is connected to the infrared probe 8 through an optical fiber; the infrared temperature measuring device 9 is connected to the control cabinet 20.

[0022] The temperature measurement system of the present invention: adopts the world's advanced non-contact infrared thermometer, which can penetrate the interference of flame and combustion gas to directly measure the temperature of the refractory material in the ladle, and obtain a true and reliable tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com