Composite modified asphalt preparation process

A preparation process and asphalt technology, which is applied in building components, building insulation materials, construction, etc., can solve the problems of insufficient blending ability, strong emulsifying ability, and inappropriateness, and achieve excellent storage stability, good compatibility, and improved The effect of low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The base asphalt is No. 70 road petroleum asphalt.

[0021] The chemical modifier composition includes: NCO-terminated prepolymer 55wt% (NCO content 21wt%) formed by the reaction of diphenylmethane diisocyanate and polyoxyethylene-propylene oxide copolyether polyol with a weight average molecular weight of 5500, vegetable oil polyol Alcohol (Polycin GR-35) 30.5wt%, 1,4-butanediol 1wt%, dibutyltin dilaurate 0.5wt%, aminopropyltriethoxysilane (KH-550) 8.7wt%, α-ene Propyl glycidyl ether 4.2wt%, antioxidant (BHT264) 0.1wt%.

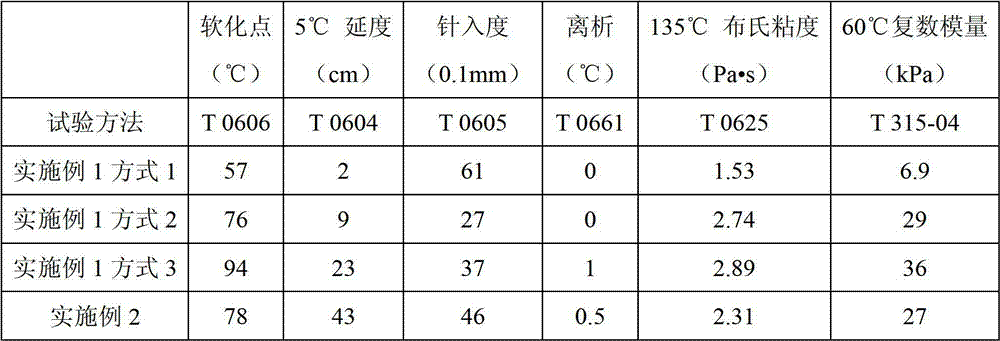

[0022] Method 1: Heat the base asphalt to 150°C, add a chemical modifier composition of 7% of its mass, and use a propeller impeller stirrer with a rotating speed of 500 rpm for 150 minutes to obtain polyurethane modified asphalt. The specific test indicators are shown in Table 1.

[0023] Method 2: Heat the base asphalt to 150°C, add a chemical modifier composition of 7% of its mass, and use a six-flat-blade disc turbine agitator with a rotation speed of ...

Embodiment 2

[0026] The base asphalt is No. 70 road petroleum asphalt; the chemical modifier composition is the same as in Example 1; the polymer modifier is the dissolution of PSBR asphalt modifier in aromatic oil, and the mass ratio of PSBR asphalt modifier to aromatic oil It's 55:45. The total added amount of the chemical modifier composition accounts for 3wt% of the base asphalt, and the polymer modifier accounts for 3wt% of the base asphalt.

[0027] The base asphalt is heated to 150°C, polymer modifier is added, and a propeller impeller stirrer with a rotating speed of 300 rpm is used to swell and mix for 60 minutes, and then a high-speed shearing device is used to shear at a speed of 5000 rpm for 30 minutes to prepare a modified asphalt master batch. Then replace the mixing equipment with a six flat blade disc turbine agitator, adjust the speed to 1750 rpm, add the chemical modifier composition at 150° C., and continue stirring for 120 minutes to obtain a composite polymer chemically m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com