Combined trough-tower concentration manner-based solar gasification system

A trough solar energy and gasification system technology, applied in the directions of energy input, joint combustion mitigation, production of combustible gas, etc., can solve the threat to the safe operation of the syngas utilization system, increase the burden of the syngas purification device, and affect the normal operation of the gasification device. Operation and other problems, to achieve the effect of optimizing heat energy utilization efficiency, reducing irreversible losses, and reducing heat energy demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

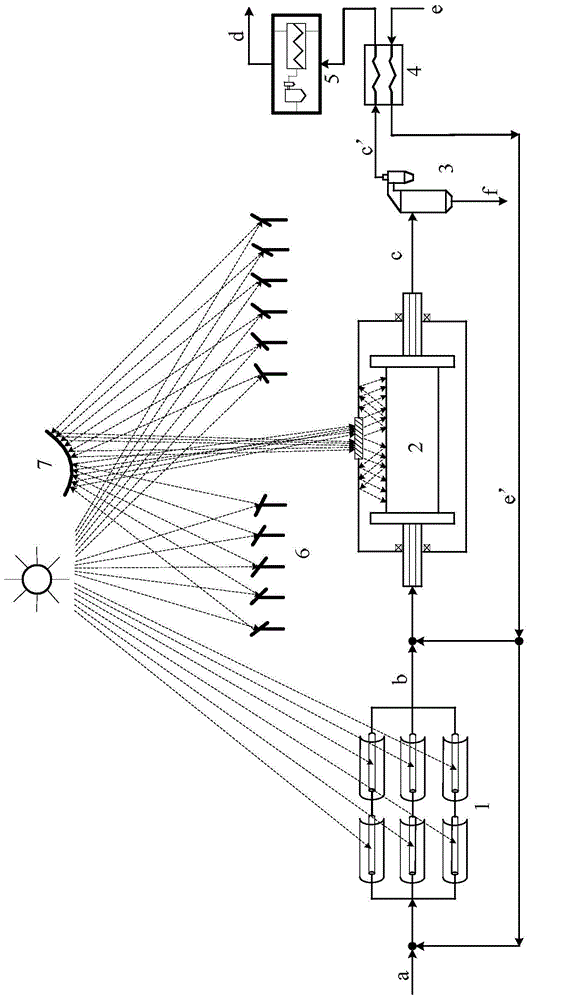

[0032] The solar gasification system based on the trough-tower combined light concentrating method provided by the present invention adopts different solar concentrating devices and reactor types to independently complete the pyrolysis and gasification reactions of solid fuels in sequence. The absorption reactor 1 realizes the pyrolysis reaction of solid fuel to obtain tar and coke, and then uses the heliostat field 6 and the hyperboloid mirror 7 to obtain solar energy with a high concentration ratio, and uses the high-temperature rotary solar gasification reactor 2 to complete tar cracking and coke Gasification and other reactions.

[0033] Such as figure 1 as shown, figure 1 It is a schematic structural diagram of a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com