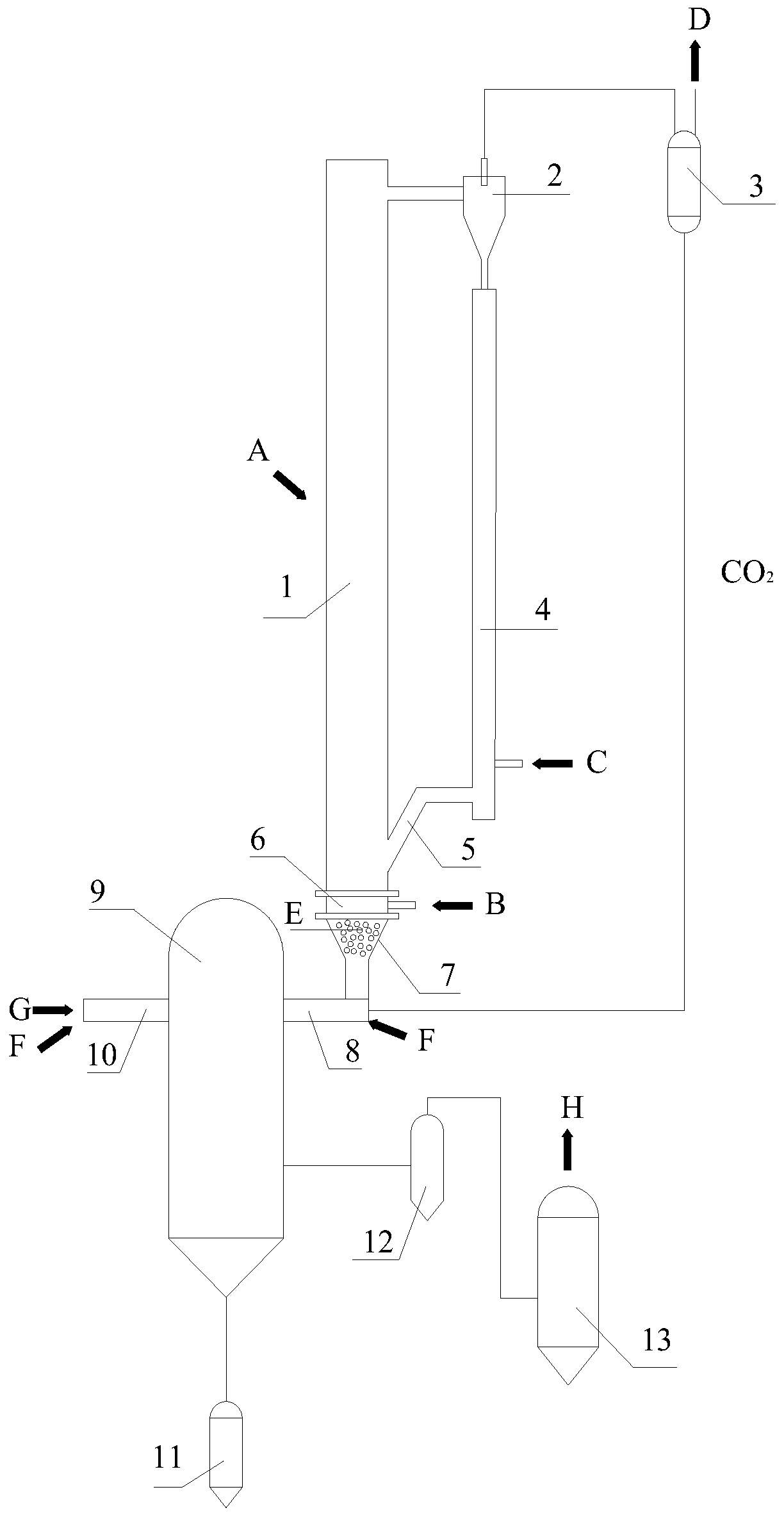

Circulating fluidized bed-entrained bed combined gasification method and device

A circulating fluidized bed and combined gasification technology, which is applied in gasification process, granular/powder fuel gasification, production of combustible gas, etc., can solve problems such as difficulty in utilizing low-rank coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

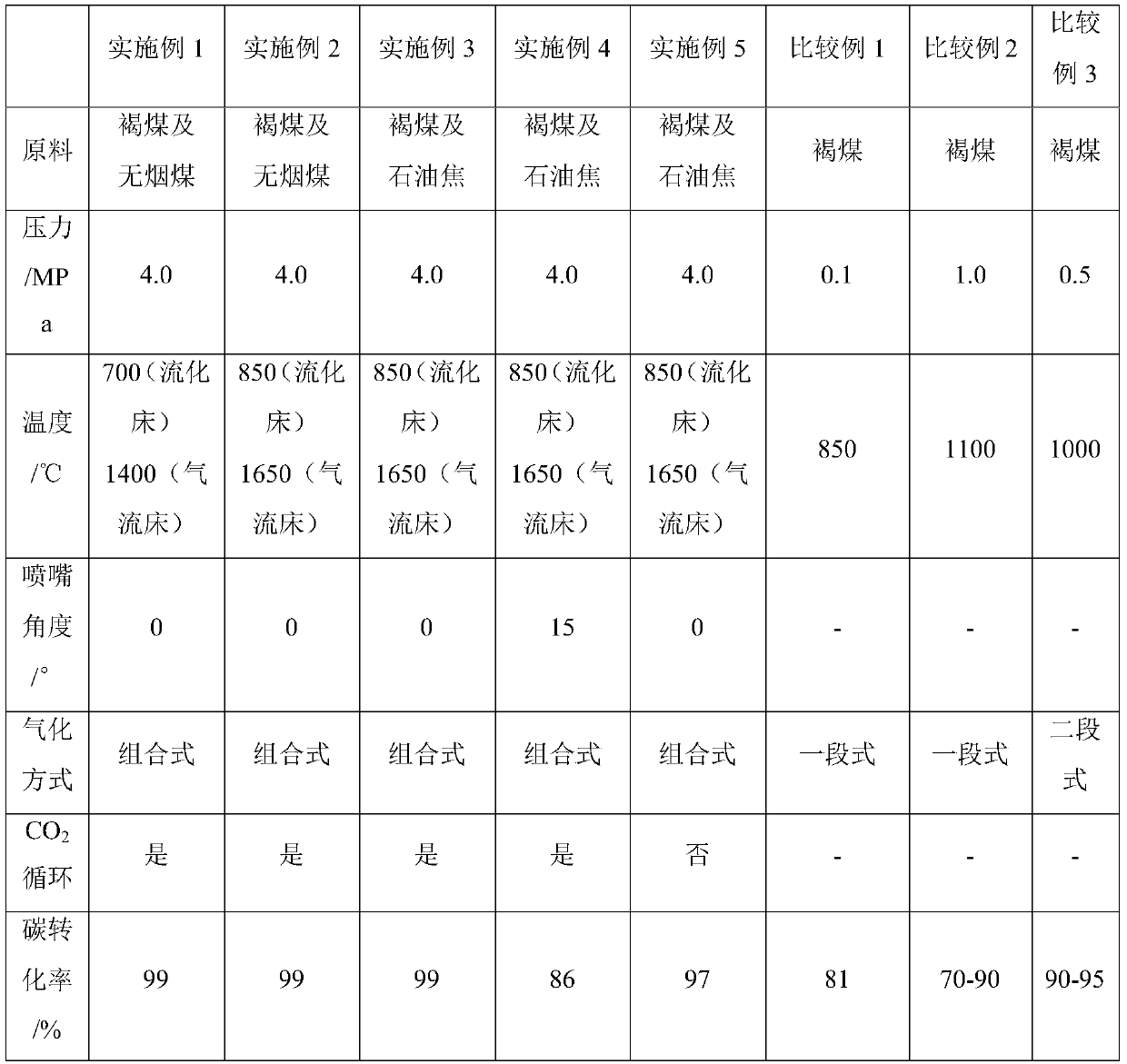

Embodiment 1

[0030] The lignite raw material containing papermaking black liquor is transported from the raw material inlet of the circulating fluidized bed riser 1 to its furnace, and the gasification agent with a ratio of 20:100 of oxygen and water vapor from the gas distributor 6 is used at an operating temperature of 700°C The reaction takes place under the environment to generate methane-rich synthesis gas and high-temperature semi-coke particles. After being separated by the first cyclone separator 2, the methane-rich first product gas D and CO which can be used as industrial fuels are obtained. 2 , wherein the first product gas D active ingredient H 2 , CO and CH 4 The contents are 41.3%, 19.6%, and 6.5%, respectively. The high-temperature semi-coke particles continue to undergo gasification reaction in the circulating fluidized bed reactor. As the combustibles in the high-temperature semi-coke particles are continuously consumed, the first ash E is finally formed, and falls from ...

Embodiment 2

[0032] The lignite raw material containing papermaking black liquor is transported from the raw material inlet of the circulating fluidized bed riser 1 to its furnace, and the gasification agent with a ratio of 25:100 of oxygen and water vapor from the gas distributor 6 is used at an operating temperature of 850°C The reaction takes place under the environment to generate methane-rich synthesis gas and high-temperature semi-coke particles. After being separated by the first cyclone separator 2, the methane-rich first product gas D and CO which can be used as industrial fuels are obtained. 2 , wherein the first product gas D active ingredient H 2 , CO and CH 4 The contents are 39.9%, 20.1%, and 7.1%, respectively. The high-temperature semi-coke particles continue to undergo gasification reaction in the circulating fluidized bed reactor. As the combustibles in the high-temperature semi-coke particles are continuously consumed, the first ash E is finally formed, and falls from ...

Embodiment 3

[0034] The lignite raw material containing papermaking black liquor is transported from the raw material inlet of the circulating fluidized bed riser 1 to its furnace, and the gasification agent with a ratio of 25:100 of oxygen and water vapor from the gas distributor 6 is used at an operating temperature of 850°C The reaction takes place under the environment to generate methane-rich synthesis gas and high-temperature semi-coke particles. After being separated by the first cyclone separator 2, the methane-rich first product gas D and CO which can be used as industrial fuels are obtained. 2 , wherein the first product gas D active ingredient H 2 , CO and CH 4 The contents are 39.9%, 20.1%, and 7.1%, respectively. The high-temperature semi-coke particles continue to undergo gasification reaction in the circulating fluidized bed reactor. As the combustibles in the high-temperature semi-coke particles are continuously consumed, the first ash E is finally formed, and falls from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com