Method for efficient resource utilization of lignite

A technology of recycling lignite, which is applied in the preparation of liquid hydrocarbon mixtures, dry distillation in special forms, and the petroleum industry, can solve the problems that lignite cannot meet the calorific value requirements of power plants, increase the yield of coal tar, improve the utilization value, and can The effect of increasing the modulation range and modulation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

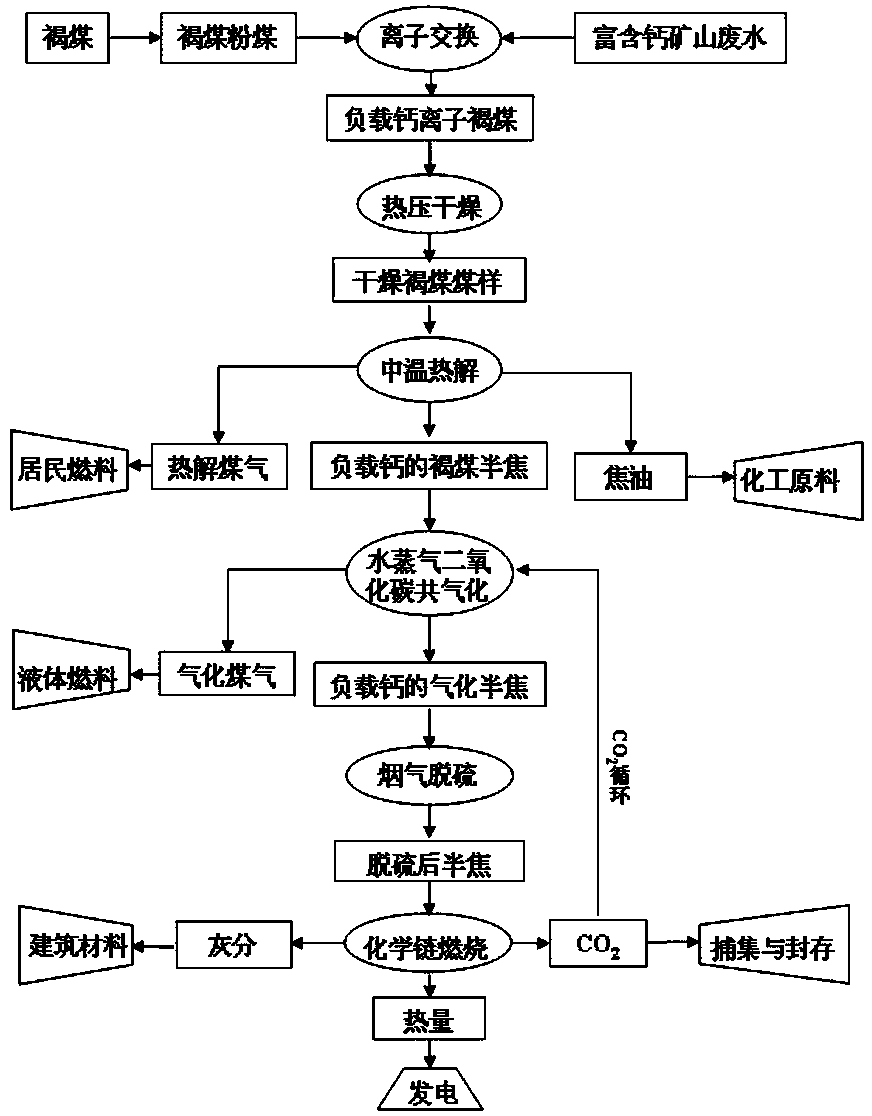

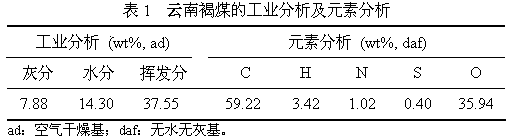

[0034] This embodiment adopts Yunnan lignite as raw material, according to figure 1 The process flow shown is for efficient resource utilization of lignite. The industrial analysis and element analysis of Yunnan lignite are shown in Table 1.

[0035]

[0036] The Yunnan lignite is crushed and screened to obtain lignite pulverized coal with a particle size below 0.3 mm. Take 50Kg of crushed lignite and add it into 200Kg of acidic mine wastewater rich in calcium ions at room temperature, and perform ion exchange for 24 hours. The composition of mine wastewater is shown in Table 2.

[0037]

[0038] After the ion-exchanged lignite is filtered by a suction filter, it is dried under hot pressure at 200° C. and 10 MPa, and the holding time is 20 minutes. After drying, the lignite is pyrolyzed at a medium temperature in a fixed-bed reactor with a pyrolysis temperature of 700°C and a pyrolysis time of 60 minutes. Pyrolysis produces pyrolysis gas, tar and semi-coke, of which ...

Embodiment 2

[0043] This embodiment adopts Inner Mongolia lignite as raw material, according to figure 1 The process flow shown is for efficient resource utilization of lignite. The industrial analysis and elemental analysis of Inner Mongolia lignite are shown in Table 3.

[0044]

[0045]The Inner Mongolia lignite is crushed and screened to obtain lignite pulverized coal with a particle size below 0.3mm. Take 50Kg of crushed Inner Mongolian lignite and add it to 300Kg of calcium ion-rich acid mine wastewater in Example 1 at room temperature, and perform ion exchange for 30 hours.

[0046] Filter the ion-exchanged lignite, and dry it under hot pressure at 220°C and 8Mpa for 15 minutes under pressure. After drying, the lignite is pyrolyzed at a medium temperature in a fixed-bed reactor with a pyrolysis temperature of 650°C and a pyrolysis time of 30 minutes. Pyrolysis produces pyrolysis gas, tar and semi-coke, of which the yield of semi-coke is 29.7Kg, with a yield of 59.3wt%, and the...

Embodiment 3

[0051] This embodiment adopts Indonesian lignite as raw material, according to figure 1 The process flow shown is for efficient resource utilization of lignite. The industrial analysis and elemental analysis of Indonesian lignite are shown in Table 4.

[0052]

[0053] The Indonesian lignite is crushed and screened to obtain lignite pulverized coal with a particle size below 0.3mm. Take 50Kg of crushed lignite and add it into 150Kg of acidic mine wastewater rich in calcium ions at room temperature, and perform ion exchange for 36 hours. The composition of mine wastewater is shown in Table 2.

[0054] Filter the ion-exchanged lignite and dry it under hot pressure at 180°C and 12Mpa for a holding time of 20 minutes. After drying, the lignite is pyrolyzed at a medium temperature in a fixed-bed reactor with a pyrolysis temperature of 800°C and a pyrolysis time of 30 minutes. Pyrolysis produces pyrolysis gas, tar and semi-coke, of which the yield of semi-coke is 30.7Kg, with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com