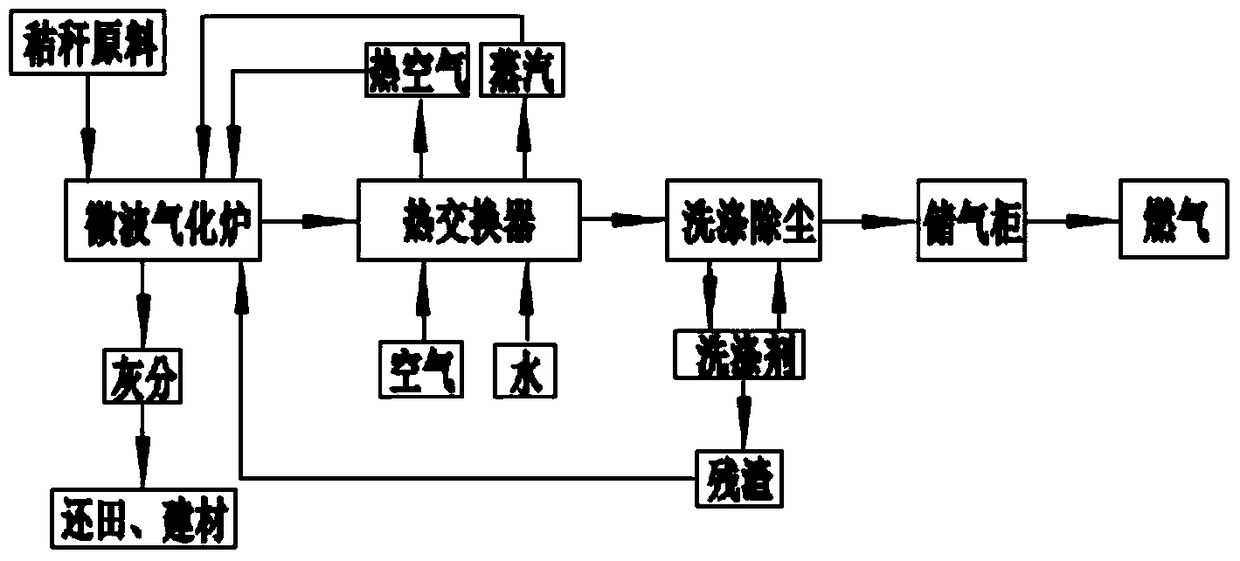

Biomass gas production system and process based on microwave heating

A microwave heating and biomass technology, applied in the field of biomass gas production system and process, can solve the problems of high operating cost, low carbon conversion rate, low heating efficiency, etc. The effect of high heat utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

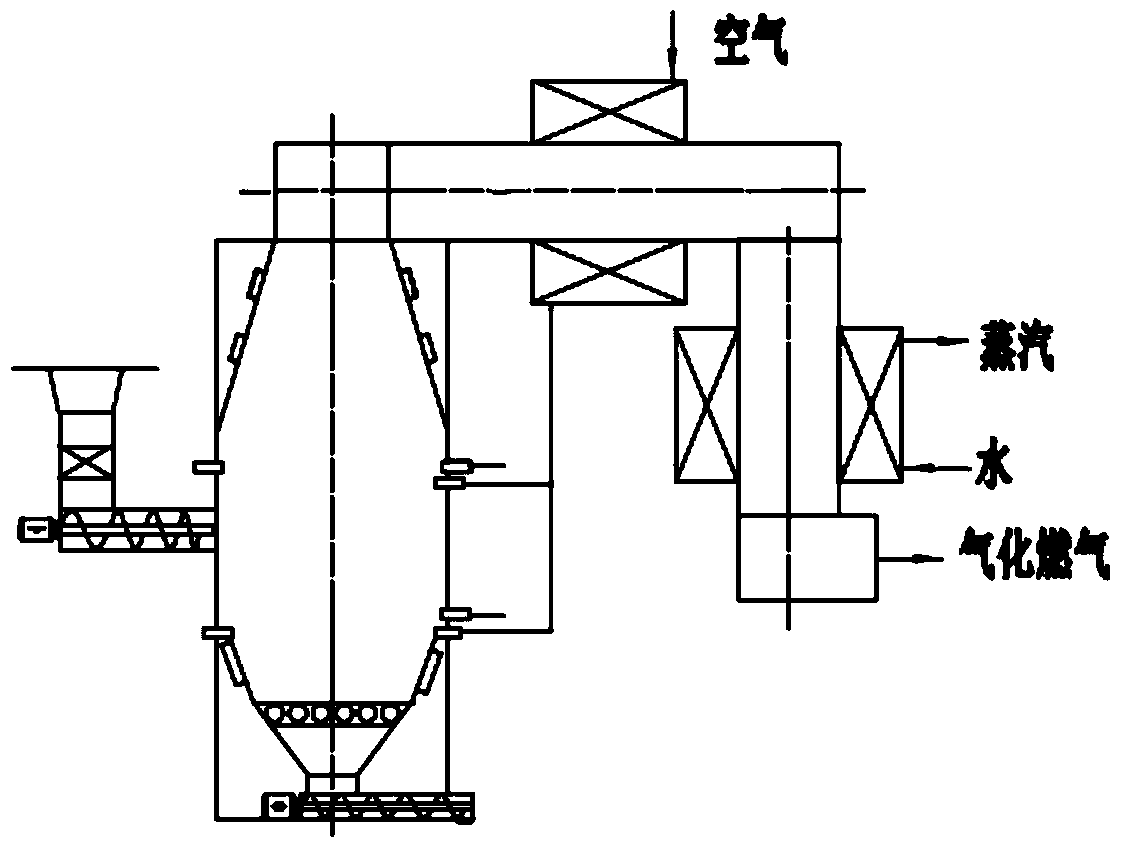

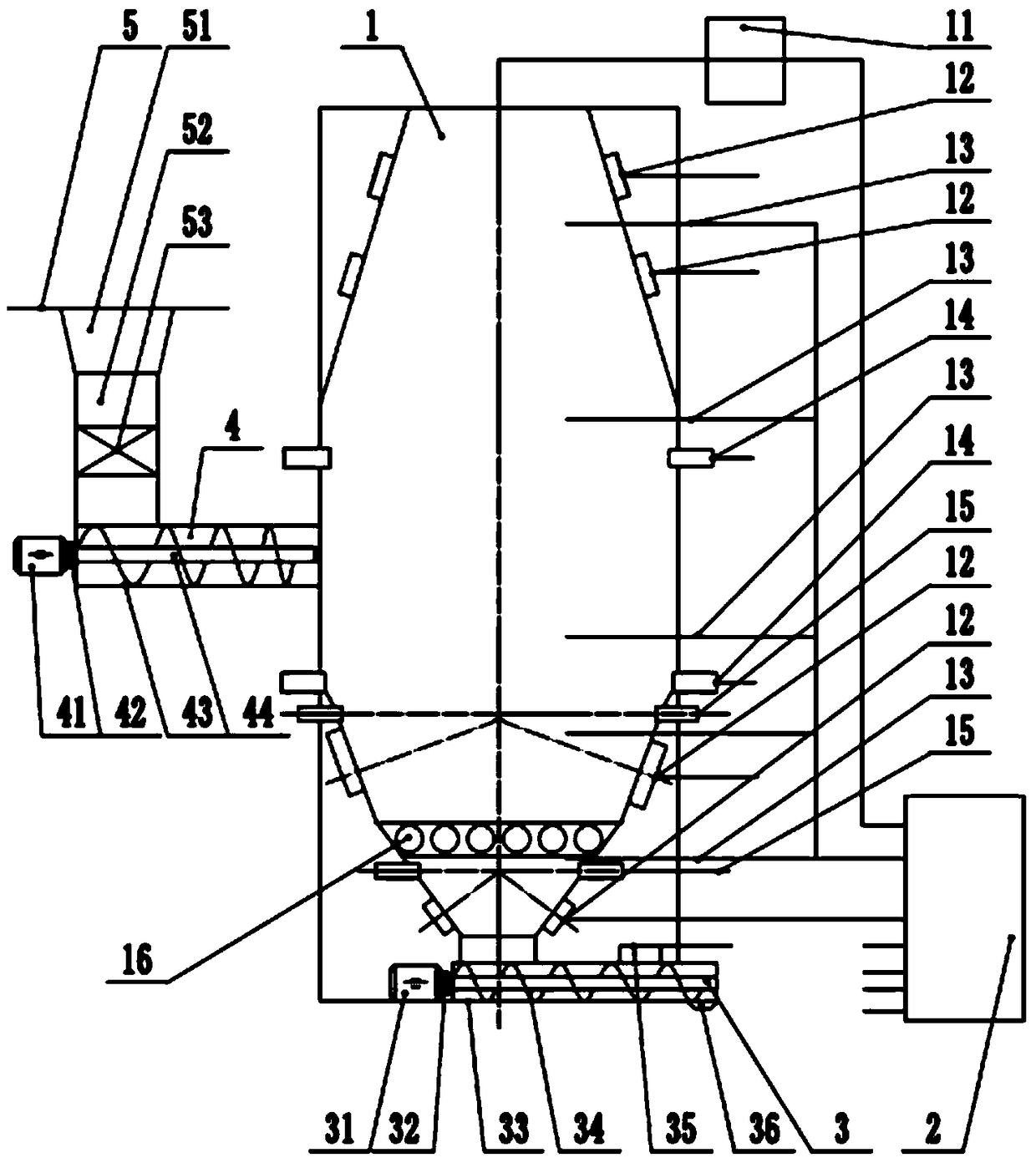

[0036] A biomass gas production system based on microwave heating, including a microwave gasifier 1 connected in sequence, a heat exchanger for exchanging heat with the high-temperature gas generated by the microwave gasifier 1, washing and dust removal equipment, and a gas storage device; heat exchange The device includes at least two stages of heat exchange devices, which input air and water respectively, and exchange heat with the high-temperature gas generated by microwave gasification furnace 1 to produce hot air and water vapor, which are then passed into microwave gasification furnace 1 as gasification medium; washing After the dehumidification treatment, the residue of the dust removal equipment leads to the feed conveying system connected with the microwave gasification furnace 1, and participates in the gasification reaction together with the biomass raw material; the microwave has strong penetrating power and generates a large amount of heat, which can quickly reach t...

Embodiment 2

[0053] The difference between this embodiment and embodiment 1 is:

[0054] There are multiple heat exchange tubes 16, the inlet of the heat exchange tubes 16 is connected to the steam outlet of the heat exchanger, and the outlet of the heat exchange tubes 16 is connected to the gas inlet of the heat exchanger.

Embodiment 3

[0056] The difference between this embodiment and embodiment 1 is:

[0057] The heat exchange tubes 16 are arranged obliquely or vertically.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com