Catalyst with cracking and gasifying function and preparation method thereof

A catalyst and oxide technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of particle size distribution broadening, loss of activity, coking precursors Concentration increases and other problems to achieve the effect of increasing the rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Weigh 4.5 kg of kaolin (Suzhou clay), of which 1.5 kg and 0.9 kg of potassium carbonate and calcium carbonate measured as oxides are mixed (all chemically pure reagents, provided by Beijing Chemical Reagent Company, potassium / calcium atomic ratio 0.1), add Beat 5.6 kg of deionized water for 10 minutes, add hydrochloric acid, adjust the pH of the slurry to 4, and stir for 30 minutes.

[0025] Mix the remaining 3 kg of kaolin with 4.3 kg of bauxite (produced by Shandong Aluminum Factory), add 20 kg of deionized water, stir for 20 minutes, add hydrochloric acid (chemically pure reagent, provided by Beijing Chemical Reagent Company), adjust the pH to 2.5, and stir for 10 Minutes, let stand for 30 minutes.

[0026] Mix the two slurries, add 3 kg of aluminum sol (produced by Qilu Catalyst Factory) while stirring, stir for 30 minutes, spray drying and shape, adjust the spray conditions to make the average particle size of 80μm. Firing at 550°C for 60 minutes, the sample number is ...

Embodiment 2~6

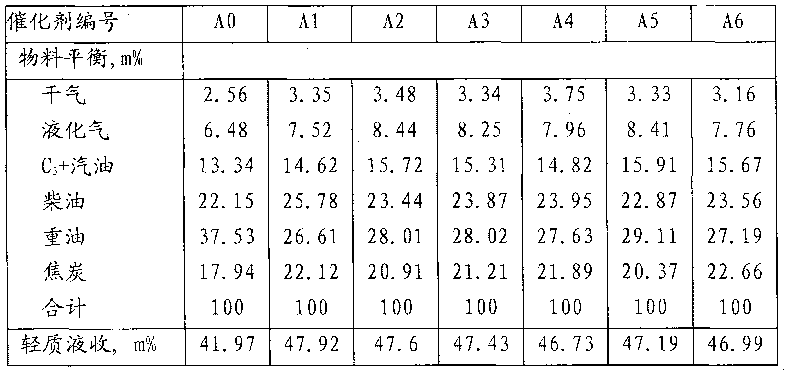

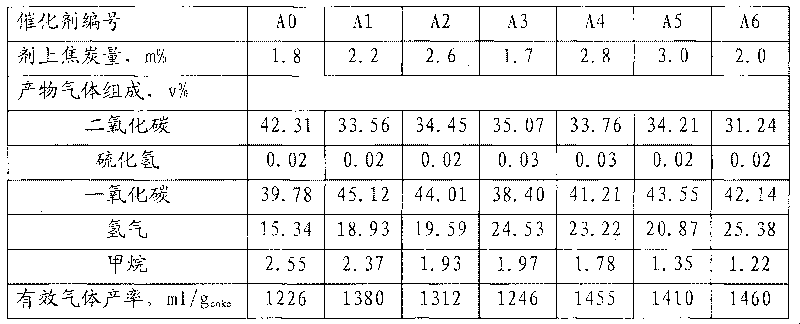

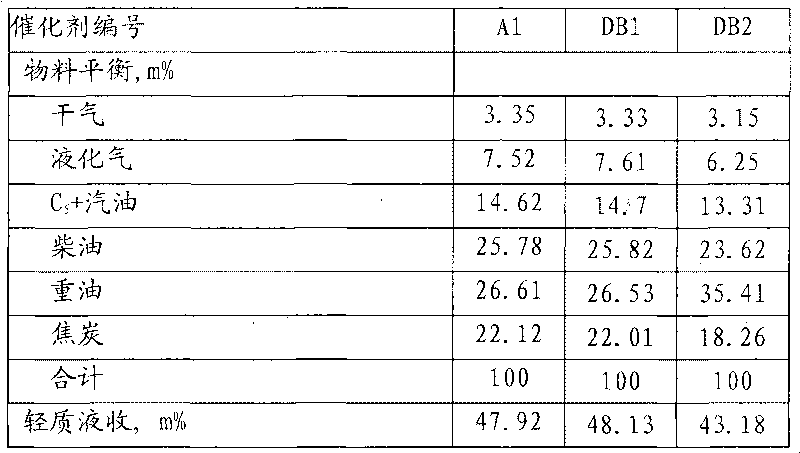

[0028] Repeat the steps of Example 1 and adjust the ratio of materials used to prepare catalyst samples numbered A2, A3, A4, A5, and A6 respectively. The composition and physical properties are shown in Table 1.

[0029] Table 1

[0030] Example number

[0031] Example number

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com