Method for catalytic gasification of petroleum coke

A petroleum coke and catalyst technology, applied in the field of petroleum coke catalytic gasification, can solve the problems of low catalytic activity of iron-based catalysts, low catalytic activity, large catalytic difference, etc., so as to achieve resource utilization, rich resources, source wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

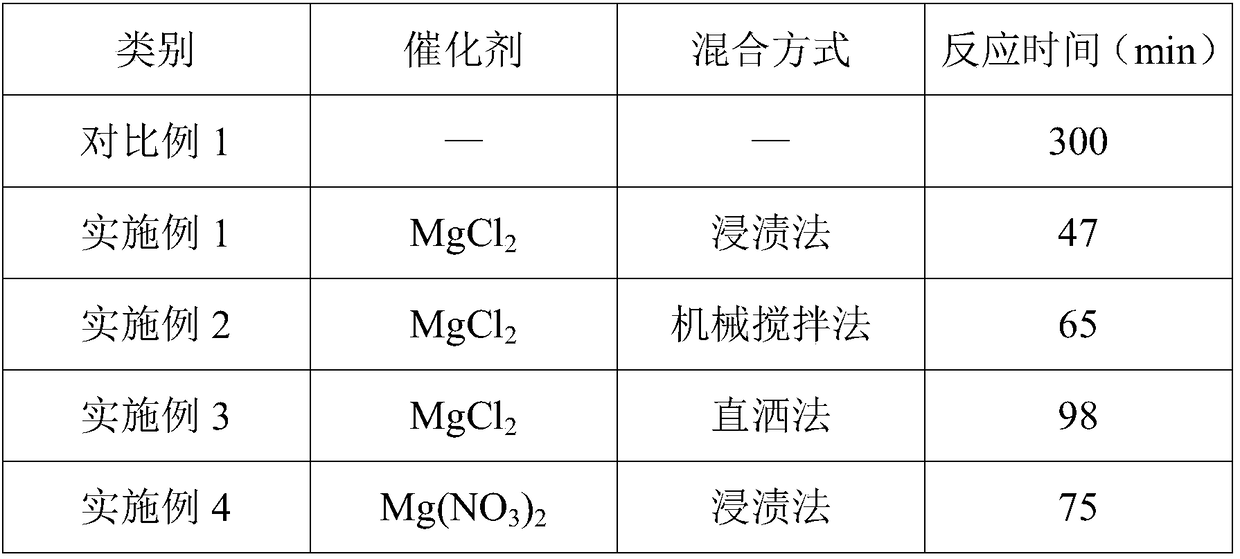

[0026] Embodiment 1: Weigh 1gMgCl 2 Put it into a beaker, and add 20g of water, stir well to get the 2 solution, then weigh 10g of petroleum coke with a particle size of less than 0.074mm, and mix it with MgCl 2 The solutions were mixed together and stirred for 24 hours with a magnetic stirrer; finally, the stirred petroleum coke was dried in a drying oven at 105°C for 12 hours to obtain catalyst-loaded petroleum coke prepared by impregnation method, and the above samples were placed in The reaction was carried out in a fixed-bed gasifier. The operating conditions of the gasifier were: pressure 0.1MPa, temperature 1100°C, water vapor flow rate 4g / min, and the time required for the complete reaction of petroleum coke is shown in Table 1.

Embodiment 2

[0027] Embodiment 2: Take by weighing 10g of petroleum coke with a particle size less than 0.074mm and 1g of MgCl 2 , the above samples were dried, ground on a vibrating grinder for 10 minutes, and then dried in a drying oven at 105°C for 12 hours to obtain catalyst-loaded petroleum coke prepared by mechanical mixing, and the above samples were put into a fixed bed gasification The reaction was carried out in the gasification furnace. The working conditions of the gasifier: the pressure is 0.1MPa, the temperature is 1100°C, the water vapor flow rate is 4g / min, and the time required for the complete reaction of petroleum coke is shown in Table 1.

Embodiment 3

[0028] Embodiment 3: Weigh 10g of petroleum coke and 1g of MgCl with a particle size less than 0.074mm 2 , after drying the above samples, the MgCl 2 Sprinkle directly on the surface of petroleum coke, put it into a fixed-bed gasifier for reaction, the working conditions of the gasifier: pressure 0.1MPa, temperature 1100℃, water vapor flow rate 4g / min, the time required for the complete reaction of petroleum coke is shown in the table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com