In-furnace desulfurization method of circulating fluidized bed boiler

A circulating fluidized bed and furnace desulfurization technology, which is applied to chemical instruments and methods, separation methods, and dispersed particle separation, can solve problems such as secondary pollution, large area occupied by desulfurization, and water resource consumption. Effect of reducing liquid bridge force and increasing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

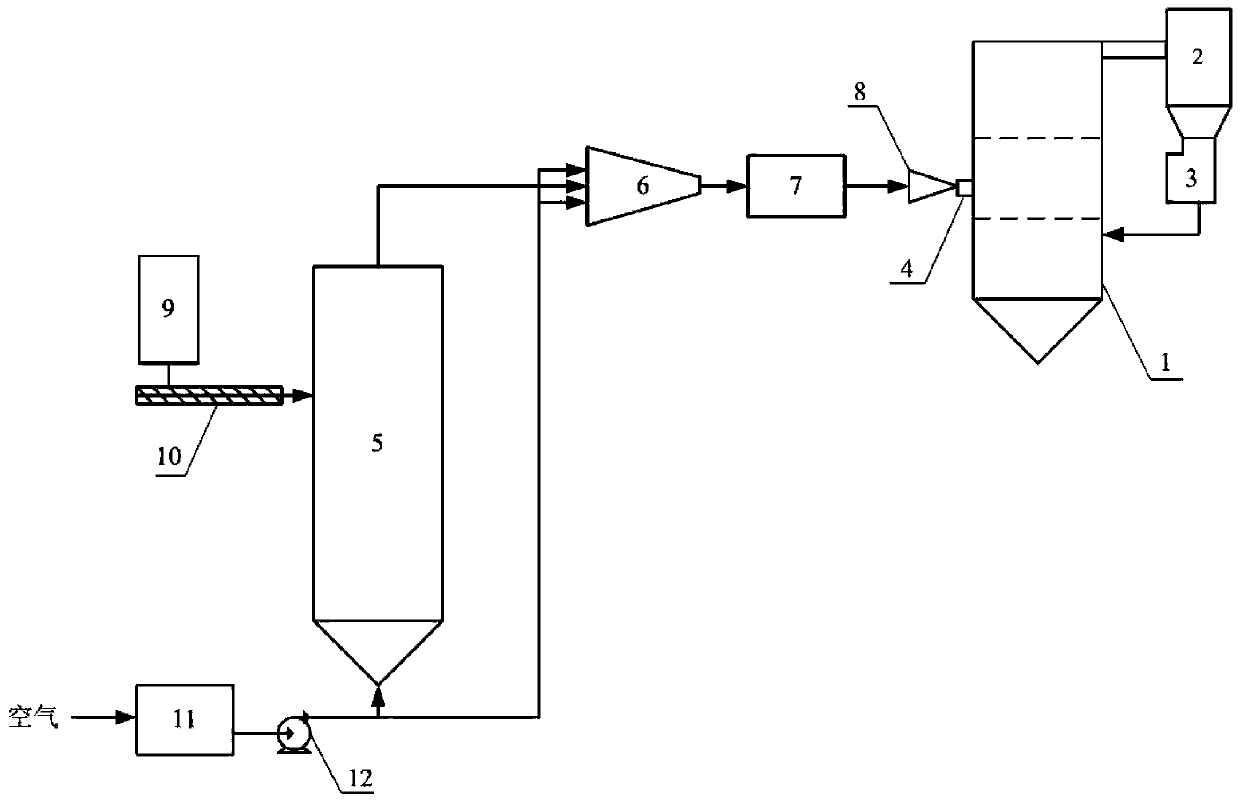

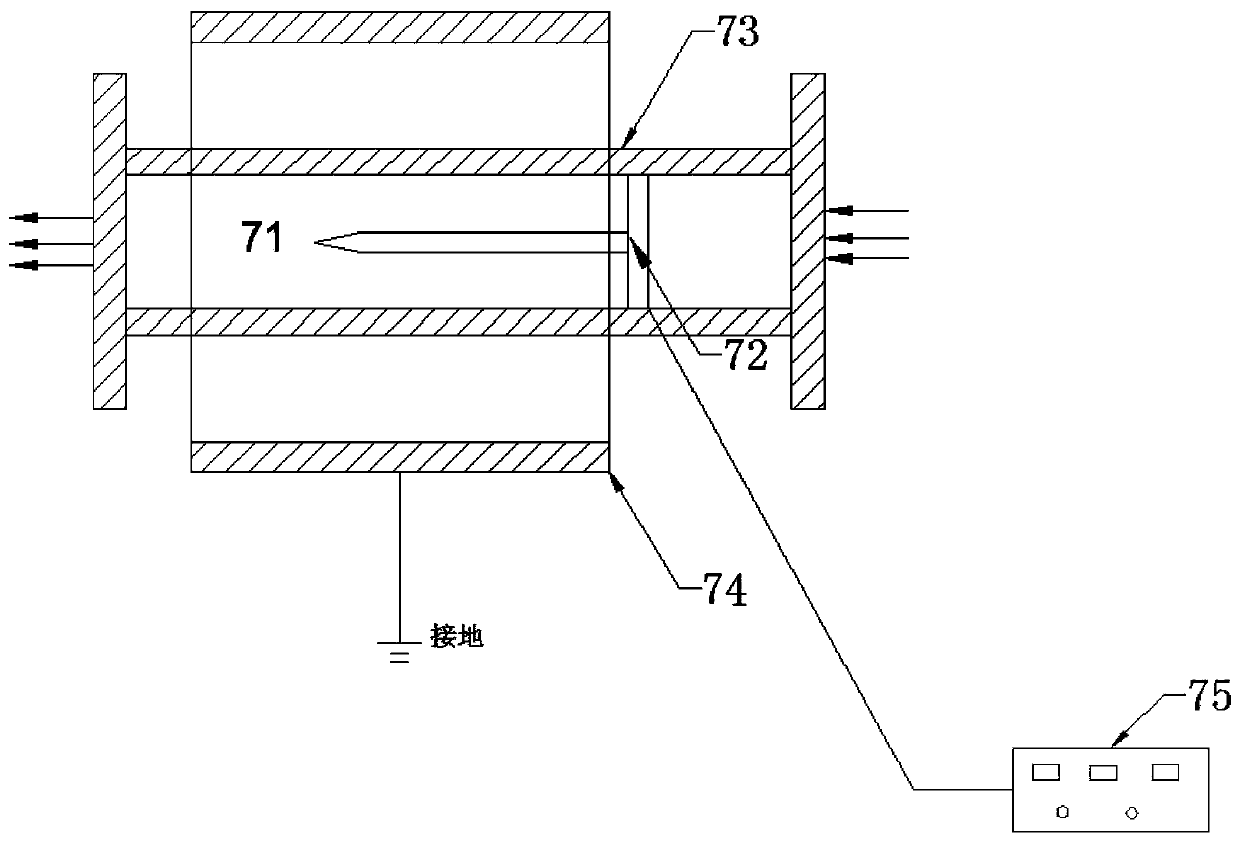

[0052] This embodiment provides a furnace desulfurization method for a circulating fluidized bed boiler, such as figure 1 As shown, the system used in the method includes a circulating fluidized bed coal-fired boiler 1, a cyclone separator 2 and a feeder 3, and the desulfurizer limestone with an average particle size of 200 μm to 300 μm is passed into the circulating fluidized bed together with the coal. The reaction is carried out in the furnace body of the boiler 1, and the Ca / S in the furnace body of the circulating fluidized bed boiler 1 is ≤ 2.5; when the SO in the circulating fluidized bed boiler 1 2 Instantaneous emission concentration > 35mg / Nm 3 At the same time, the ultrafine composite additive is sent from the secondary tuyere 4 of the circulating fluidized bed boiler 1 into the circulating fluidized bed boiler 1 through the ultrafine composite additive dispersion and injection system to perform desulfurization in the furnace.

[0053] like figure 1 As shown, the ...

Embodiment 2

[0061] This embodiment provides an in-furnace desulfurization method for a circulating fluidized bed boiler. The method refers to the method in Embodiment 1, except that the average particle size of the desulfurizing agent limestone is 100 μm-200 μm.

[0062] Using the method described in this example, the desulfurization efficiency of the circulating fluidized bed boiler can reach 97%, and the SO in the final discharged flue gas 2 The concentration of 3 .

Embodiment 3

[0064] This embodiment provides an in-furnace desulfurization method for a circulating fluidized bed boiler. The method refers to the method in Embodiment 1, except that the average particle size of the desulfurizing agent limestone is 400 μm-500 μm.

[0065] Using the method described in this example, the desulfurization efficiency of the circulating fluidized bed boiler can reach 96%, and the SO in the finally discharged flue gas 2 The concentration of 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com