Method for controlling coarse crystallization of semi-hydrated gypsum

A hemihydrate gypsum and crystallization technology, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of inaccurate and stable control of sulfuric acid concentration, unstable control of hemihydrate gypsum crystallization, and clogging of hemihydrate filter cloths, etc. , to achieve the effect of reducing the filter area, increasing the reaction residence time, and improving the filtration capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

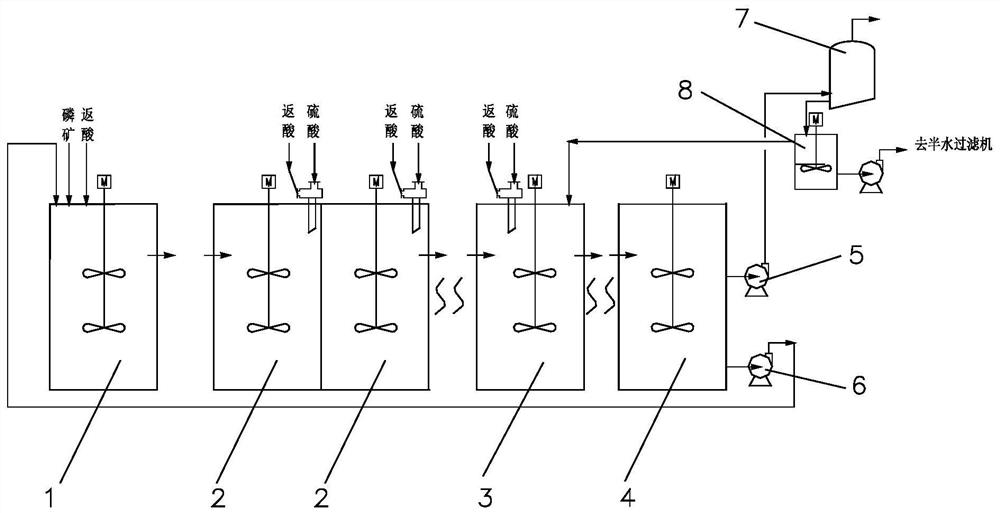

[0025] 1. Including sending the phosphate rock into the premixing zone 1 first, mixing it with back acid, and quickly decomposing it; controlling the sulfate ion concentration in the liquid phase of the premixing zone 1 to be lower than the CaO concentration by 3.6wt% to 4.6wt%, and the temperature is 90 ℃~100℃;

[0026] Two, the slurry out of the premixing zone 1 is sent into the dissolution zone 2, fully dissolved in the presence of back acid and sulfuric acid, wherein, the sulfate ion concentration in the control liquid phase is lower than the CaO concentration of 2.7wt% to 3.4wt% ;

[0027] Three, the reaction slurry that goes out dissolving zone 2 is sent in the crystallization zone 3, under the presence of the vitriol oil, crystallization grows up, and wherein, the sulfate ion concentration in the control liquid phase is higher than CaO concentration 1.2wt%~6wt%, temperature 90℃~100℃, phosphoric acid concentration is 36wt%~42wt%P 2 o 5 , with a solid content of 28wt% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com