Method for preparing DL-methionine

A technology of methionine and methionine salt, which is applied in the chemical industry to achieve the effects of high purity, uniform distribution and good yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

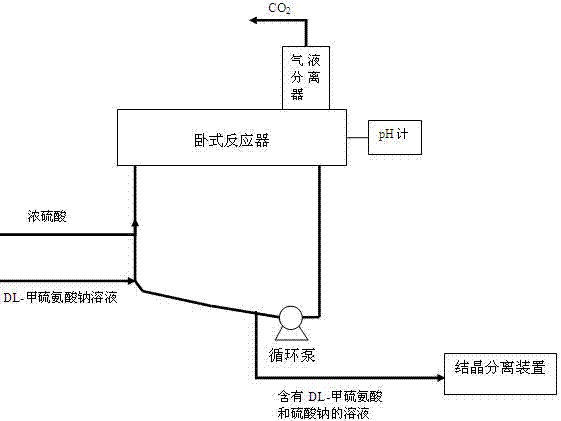

[0020] The schematic diagram of the device of the present invention is as figure 1 shown. The preparation device of DL-methionine comprises a reaction device and a crystallization separation device, the reaction device is a horizontal reactor, the liquid outlet of the horizontal reactor communicates with the inlet of the circulation pump, and the outlet of the circulation pump They are respectively communicated with the liquid inlets of the horizontal reactor and the crystallization separation device, and the circulation pump is communicated with the horizontal reactor to form a circulation system whose total volume is equivalent to 3-5 times of the feed volume.

[0021] As a preferred embodiment of the device of the present invention, the gas outlet of the horizontal reactor is also provided with a gas-liquid separator; the horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com