Light catalyst reaction device and processing technique for continuous degrading waste water containing organic contamination

A technology for photocatalytic reaction and organic pollutants, which is applied in the field of high-efficiency photocatalytic reaction devices and its treatment, can solve the problems of short light residence time of wastewater to be treated, reduced photocatalytic efficiency and activity, and difficult separation and recovery of catalysts, etc., to achieve increased The wastewater treatment capacity, the depth of degradation can be adjusted, and the effect of prolonging the reaction residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Put the whiskers of potassium tetratitanate into 100 times the mass of water, and continuously add sulfuric acid to exchange potassium ions with hydrogen ions in the solution. The acidity meter controls the pH of the solution to 1, and after fully reacting, wash with water until neutral , sintered at 500 °C for 2 h to prepare fibrous TiO 2 catalyst. XRD analysis shows that it is anatase TiO 2 . Its average diameter: 0.5-3.0 μm, length: 5-100 μm.

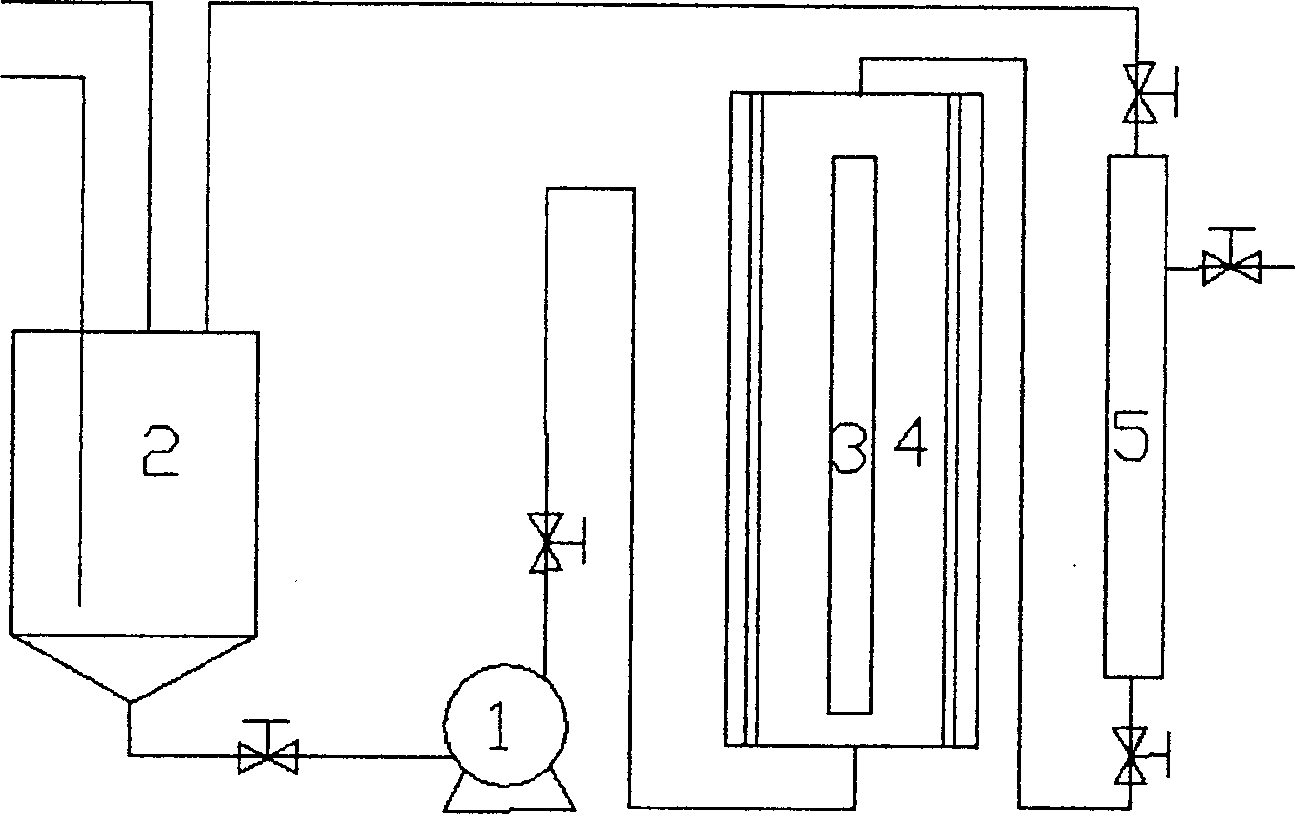

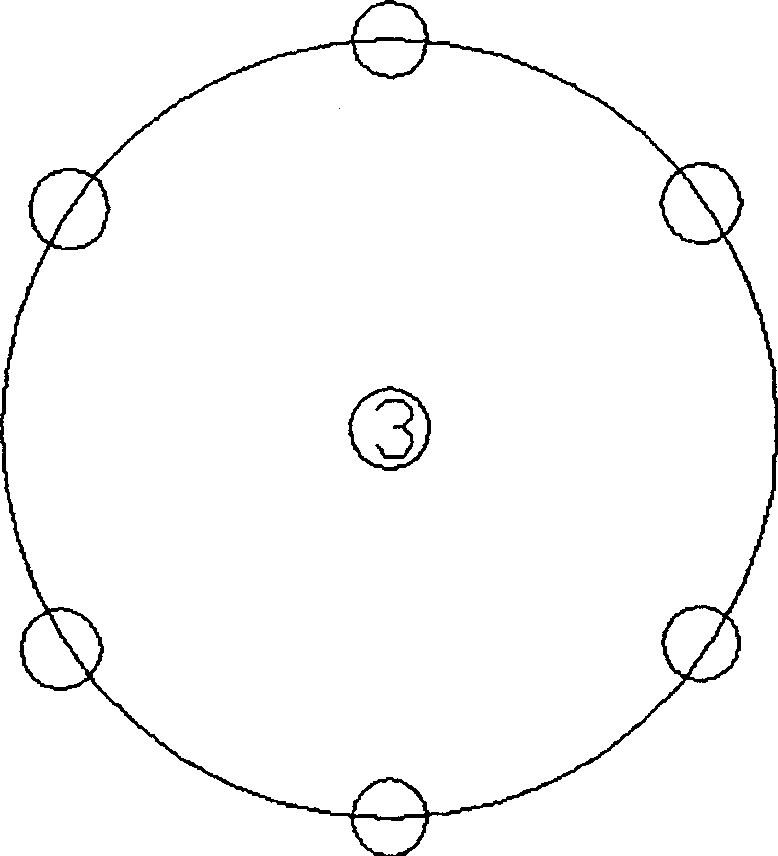

[0032] The photoreactor adopts 6 photoreaction tubes to be parallel and evenly distributed around the lamp tube 3, the distance between the lamp tube and the photoreaction tube is 150mm, the diameter of the photoreaction tube is 25mm, and the length of the lamp tube and the photoreaction tube is 1000mm.

[0033] The wastewater treatment process flow of the present invention is as described above.

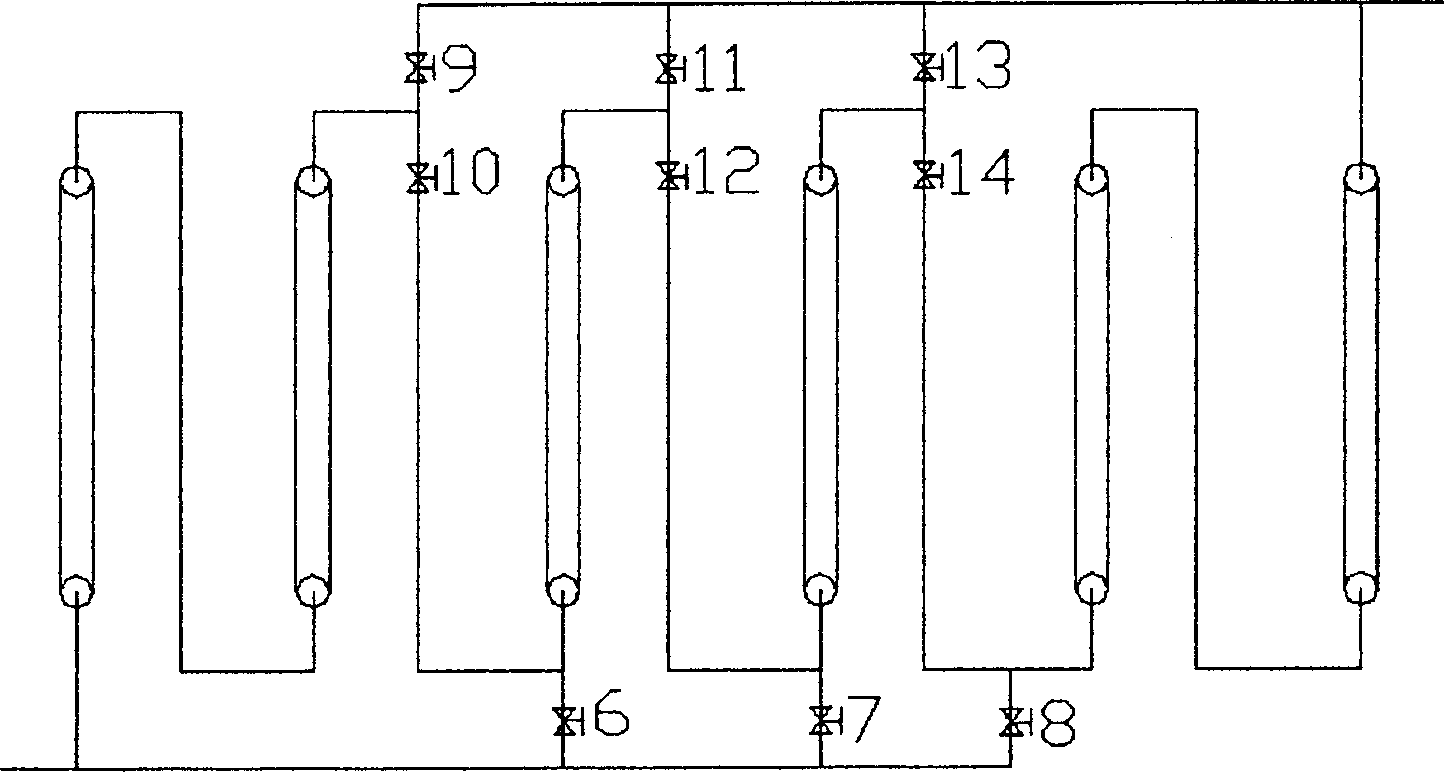

[0034] closure figure 2 Middle valves 6, 7, 8, 9, 11, 13, open valves 10, 12, 14, put the photoreaction tubes in series, us...

Embodiment 2

[0039] Add 5 g of the catalyst in Example 1 into a chloroplatinic acid solution equivalent to 0.5 wt % of the catalyst amount, then add 50 ml of 2-propanol, illuminate with a 300 W medium-pressure mercury lamp for 3 h under stirring, filter and dry, and obtain a deposit of 0.5 Modified fibrous TiO with wt% platinum 2 as a catalyst. Close the valves 6, 7, 8, 9, 11, 13, open the valves 10, 12, 14, make the photoreaction tubes in series, use the initial concentration of 1mmol / L chloroform solution as the waste water to be treated, add the catalyst concentration to be 0.5g / L, through oxygen bubbling, the pump flow rate is 40L / h, and the degradation rate of chloroform in the wastewater discharged after light is 98%.

Embodiment 3

[0044] Commercial TiO produced by Beijing Chemical Plant 2 The photocatalytic reaction was carried out after activation at a constant temperature of 500°C for 2h. Close valves 7, 10, 11, 14, open valves 6, 8, 9, 12, 13, make the photoreaction tubes in 2 series and 3 parallel states, use the methyl orange solution with an initial concentration of 5mg / L as the wastewater to be treated, Added prooxidant H 2 o 2 The concentration is 3ml / L, the pump flow rate is 120L / h, and the degradation rate of methyl orange in the wastewater discharged after illumination is 47%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com