Multi-nozzle gasification furnace with top auxiliary burners and application of multi-nozzle gasification furnace

A gasification furnace and multi-nozzle technology, applied in the field of coal chemical industry, can solve the problems of high-temperature waste heat not efficiently recovered, low carbon conversion rate, and high carbon residue, so as to improve the level of comprehensive energy utilization, increase the success rate of ignition, and improve conversion rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

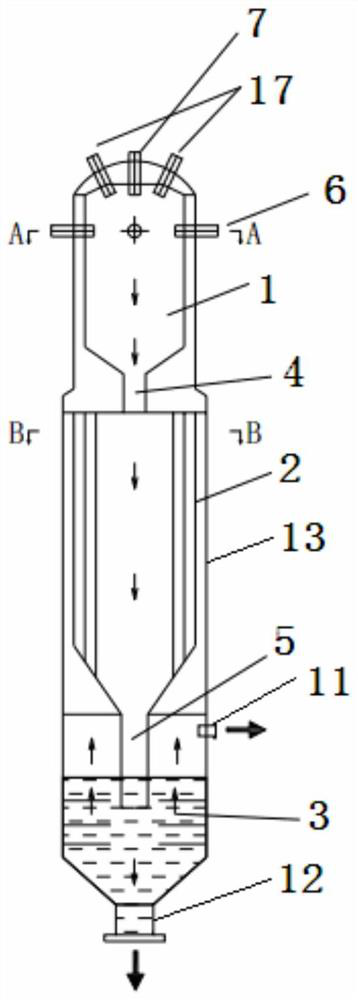

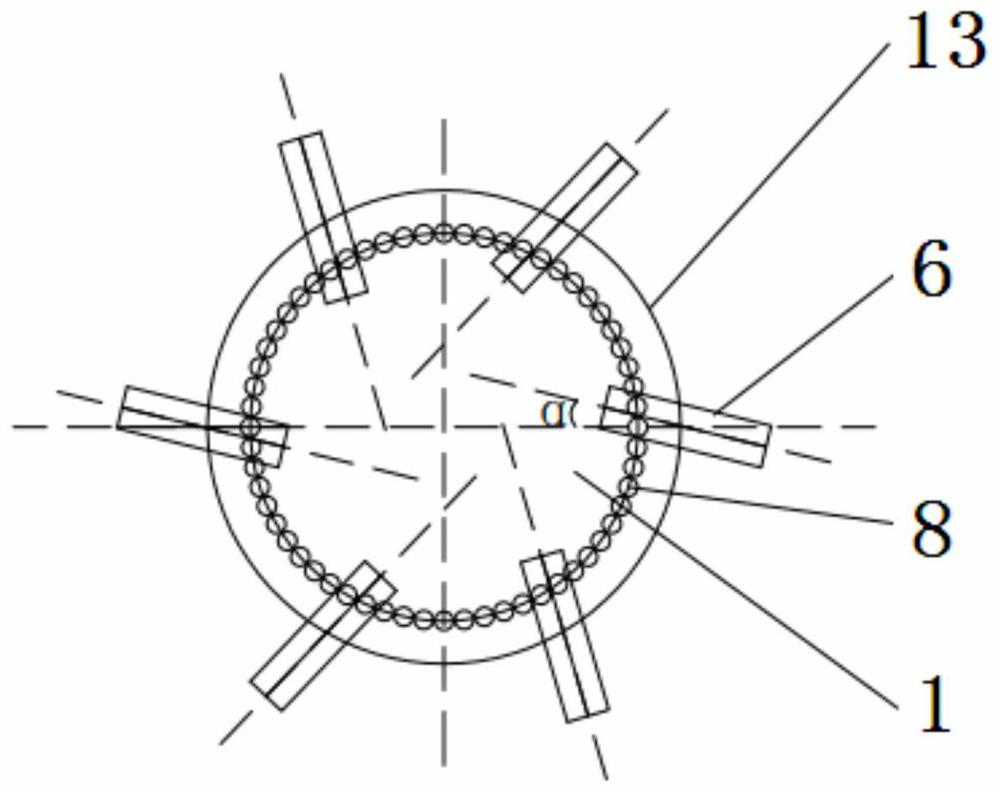

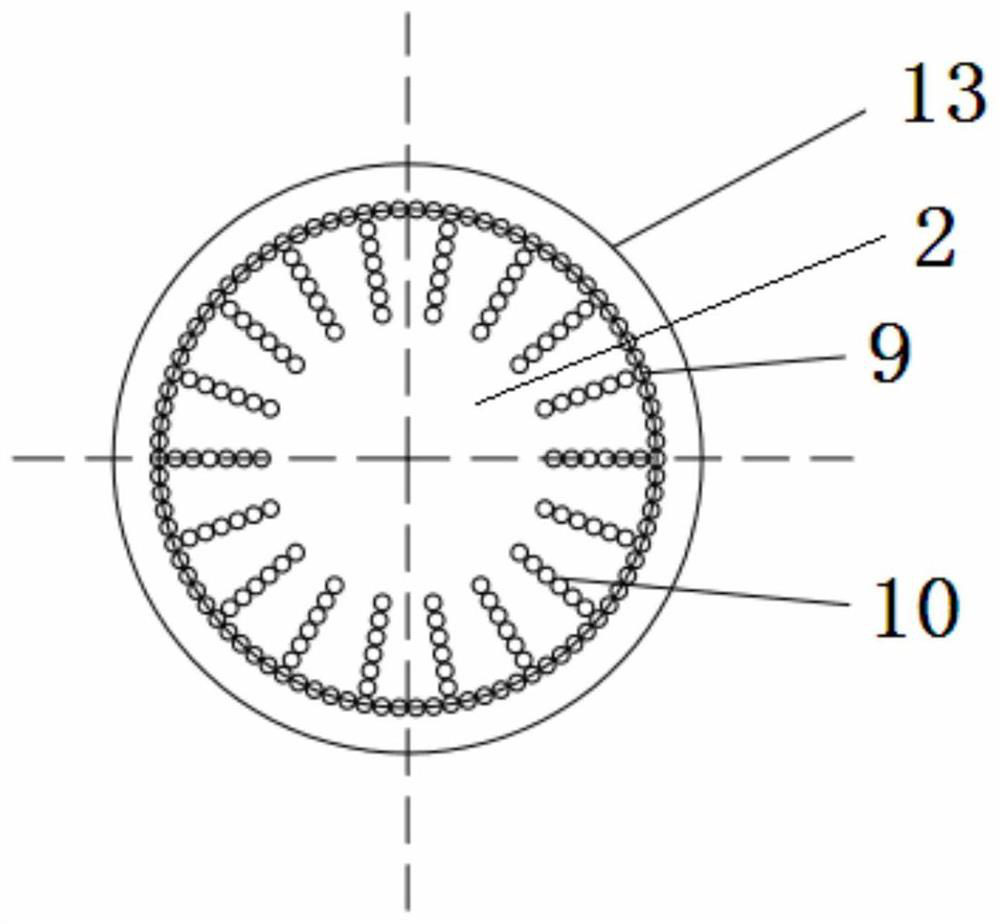

[0129] The multi-nozzle gasification furnace in this application is used for processing. Firstly, the fuel and combustion-supporting gas are input into the reaction chamber through the ignition start-up burner to start the operation after ignition, temperature rise and pressure increase, and then the first pulverized coal and the first gasification agent are input through the auxiliary burner. Auxiliary feed, the second pulverized coal and the second gasification agent feed are input through the main burner, and the gasification reaction is carried out at a pressure of 4.3MPa(g) and a temperature of 1500°C to obtain a high-temperature crude synthesis at a temperature of 1450°C gas and molten ash. Wherein, the fuel is diesel oil, and the combustion-supporting gas is oxygen. The first pulverized coal and the second pulverized coal are dry pulverized coal, the pulverized coal has a particle size of ≤90 μm accounting for 90 wt%, and the pulverized coal has a particle size of ≤5 μm...

Embodiment 2

[0133] The multi-nozzle gasification furnace in this application is used for processing. First, the fuel and combustion-supporting gas are input into the reaction chamber through the ignition start-up burner to start the process after ignition, temperature rise and pressure increase, and the second pulverized coal and second gasification agent are input through the main burner. The gasification reaction is carried out at a pressure of 4.3MPa(g) and a temperature of 1600°C to obtain high-temperature crude synthesis gas and molten ash at a temperature of 1550°C. Wherein, the fuel is natural gas, and the combustion-supporting gas is oxygen. The second pulverized coal is dry pulverized coal, and the particle size of the pulverized coal is 90wt% with a particle size of ≤90 μm and 10wt% with a particle size of ≤5 μm. The typical value of the moisture content of the pulverized coal is ≤5wt%. The second gasifying agent is a mixture of pure oxygen (oxygen content 99.7V%) and steam, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com