Reacting device

A reaction device and reaction technology, applied in the fields of chemical industry and medical machinery, can solve the problems of limited flow distance of reaction fluid, short reaction residence time, limited reaction efficiency, etc., achieve long residence time, improve sufficient mixing degree, and improve production safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

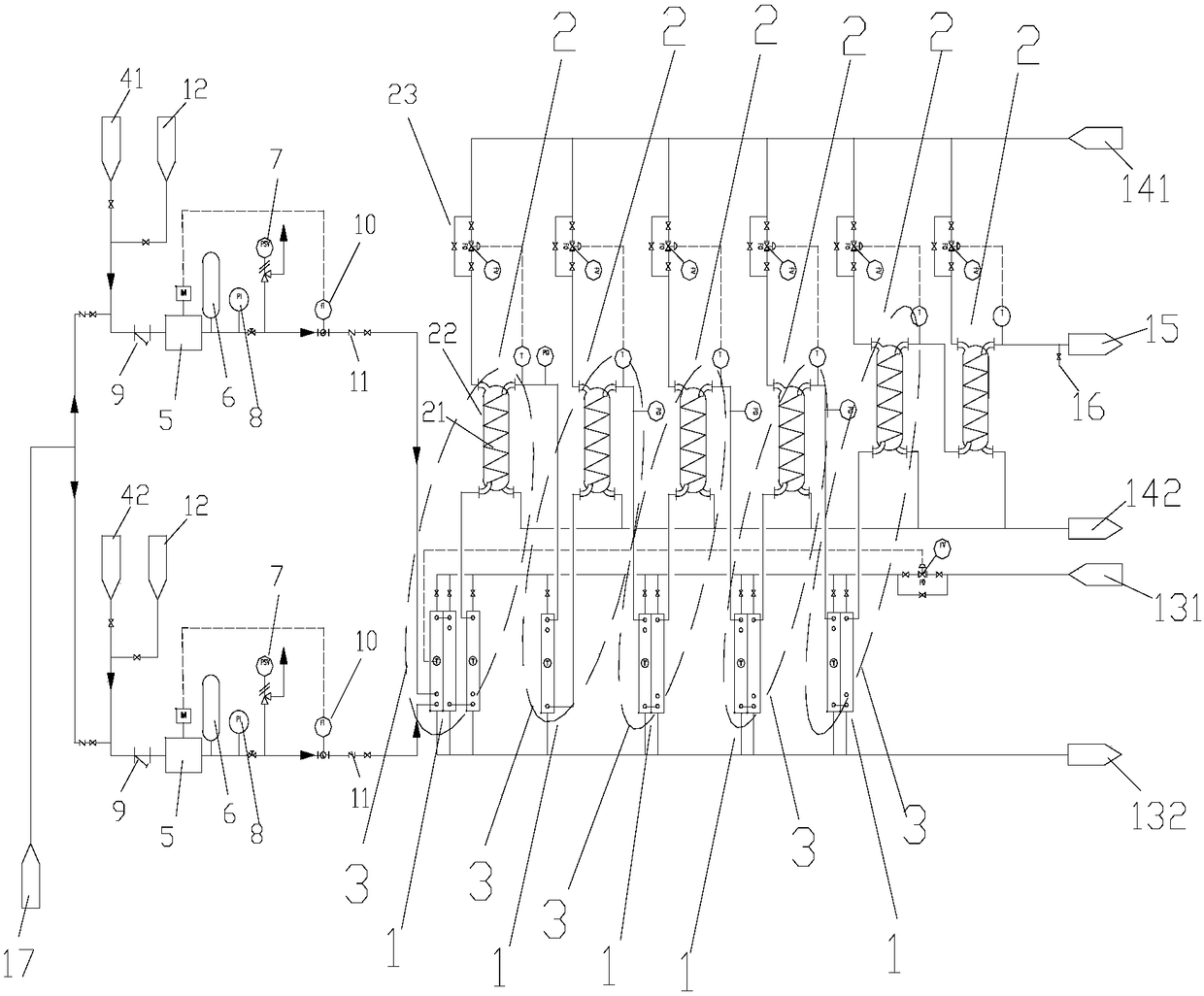

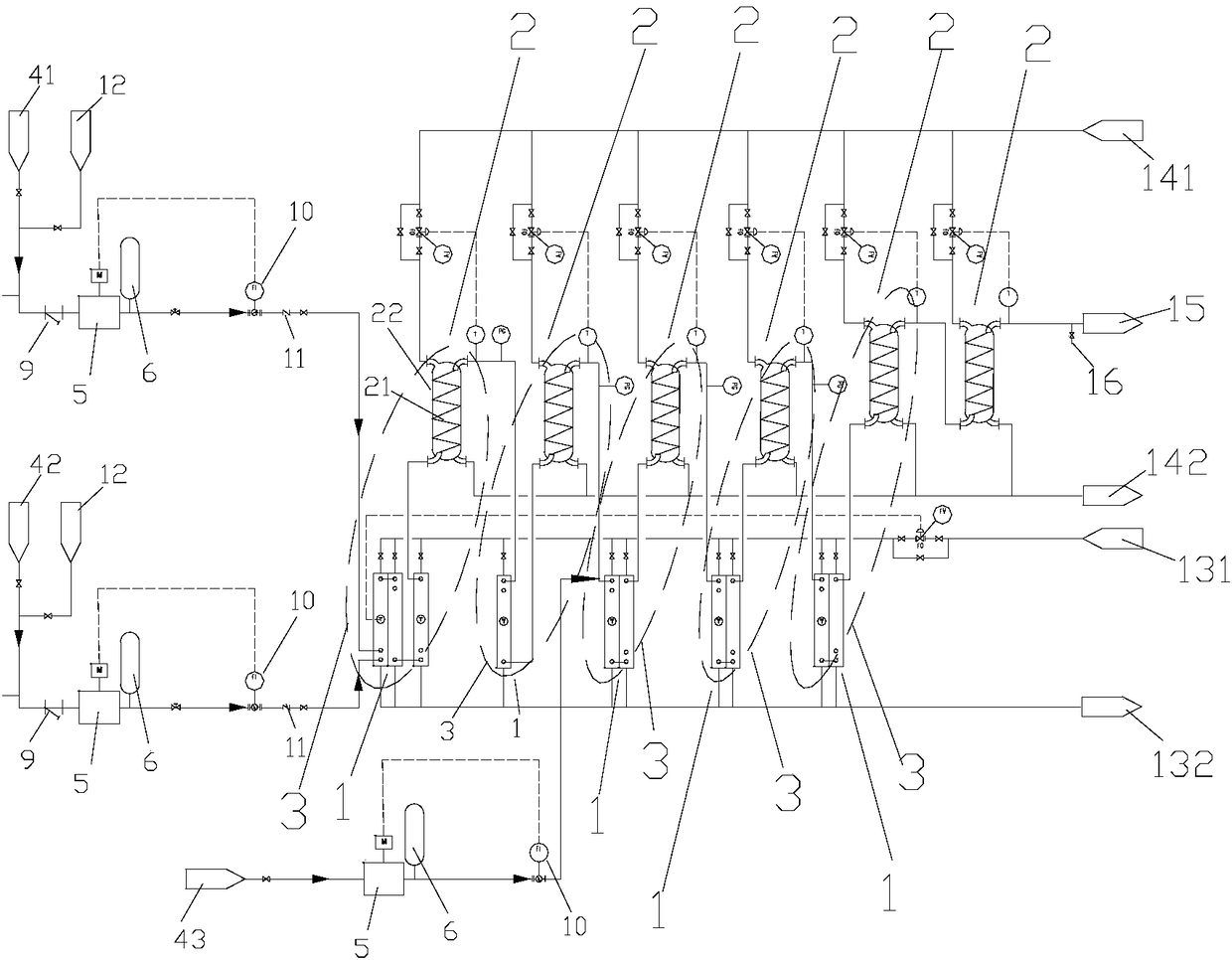

[0032] like Figure 1-2 Shown, the invention provides a kind of reaction device, it comprises:

[0033] Including microreactor 1, also includes tubular reactor 2, and along the direction of reaction fluid flow, described tubular reactor 2 is positioned at the downstream of described microreactor 1, and described tubular reactor 2 and all The microreactors 1 are connected in series.

[0034] In the reaction device of the present invention, by connecting a tubular reactor in series downstream of the microreactor in the direction of the flow of the reaction fluid, it is possible to realize that the reaction material enters the tubular reactor after relatively vigorous mixing in the microreactor To carry out a relatively stable reaction in the microreactor; effectively solve the problem that the material pressure will continue to decrease due to the action of the microchannel wall when the reaction material has been flowing in the microreactor, and can ensure or increase the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com