Process for preparing thin-layer artificial meat by heterogeneous spraying method

A technology of spray method and artificial meat, which is applied in the technical field of preparing thin-layer artificial meat by heterogeneous spray method, which can solve the problems of low toughness and poor taste, and achieve the effects of improving toughness, reducing thickness and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

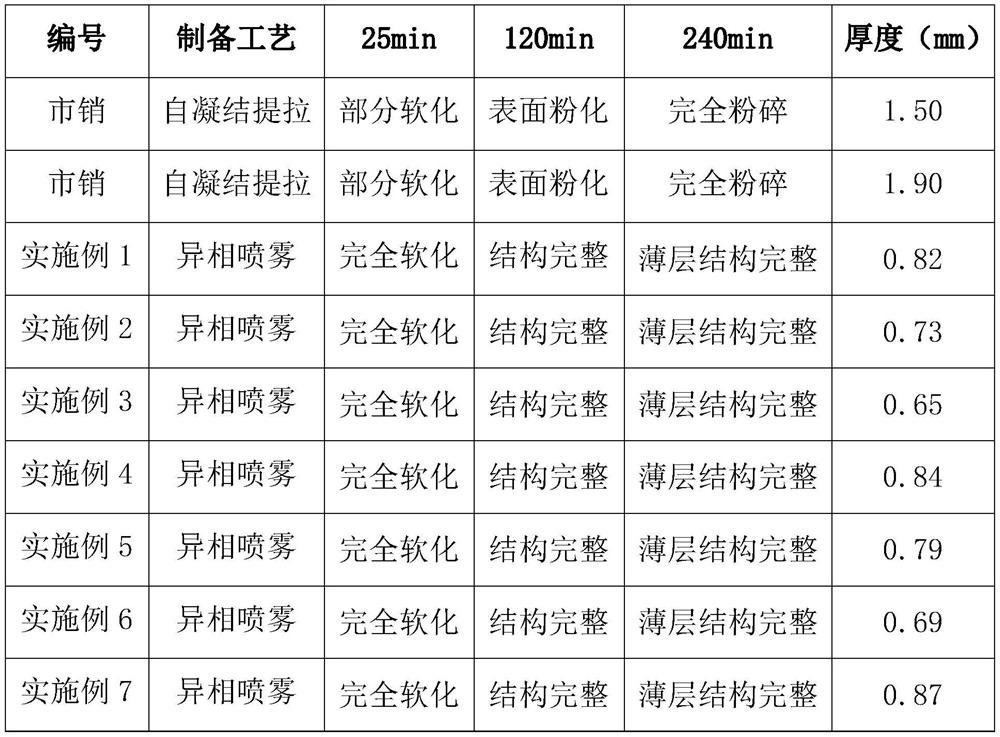

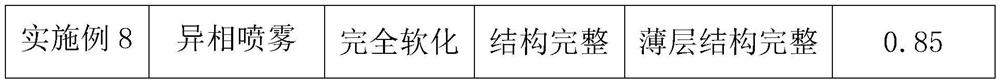

Examples

Embodiment 1

[0029] Weigh 30g of soybean protein powder and put it in 1L of pure water, and mix it evenly under ultrasonic to obtain the emulsion of soybean protein; then weigh 5g of sodium alginate powder, put it in 100mL of pure water and mix it evenly, and mix it with soybean after ultrasonic dispersion The protein emulsion is mixed evenly to obtain the coagulation base phase in this embodiment;

[0030] Weigh a total of 5g of calcium bicarbonate, place it in 1L of pure water, stir the solution, then add a total of 1.0g of carrageenan, and ultrasonically stir and disperse to obtain a homogeneous mixed solution as an induced phase;

[0031] Weigh 5g of calcium lactate and dissolve it in 1L of purified water as a solidification solution for later use.

[0032] Raise the temperature of the induction phase and solidification base phase configured above to 45°C, spray the induction phase onto the surface of the solidification base phase after atomization, and let it stand for 25 minutes to i...

Embodiment 2

[0034] Weigh 40g of soybean protein powder, place it in 1L of pure water, and mix it uniformly under ultrasound to obtain an emulsion of soybean protein; then weigh 7g of sodium alginate powder, place it in 100mL of pure water, mix it evenly, and mix it with soybean after ultrasonic dispersion The protein emulsion is mixed evenly to obtain the coagulation base phase in this embodiment;

[0035] Take calcium chloride, calcium hydroxide and add up to 10g, place 1L pure water, stir solution, then add xanthan gum, methyl cellulose and add up to 5g, ultrasonic stirring disperses, obtains homogeneous mixed solution, as induced phase;

[0036] Weigh 20g of calcium lactate and dissolve it in 1L of purified water as a solidification solution for later use.

[0037] Raise the temperature of the induction phase and solidification base phase configured above to 55°C, spray the induction phase onto the surface of the solidification base phase after atomization, and let it stand for 20 minu...

Embodiment 3

[0039] Weigh 50g of soybean protein powder, place it in 1L of pure water, and mix it uniformly under ultrasonic to obtain an emulsion of soybean protein; then weigh 8g of sodium alginate powder, place it in 100mL of pure water, mix it evenly, and mix it with soybean after ultrasonic dispersion The protein emulsion is mixed evenly to obtain the coagulation base phase in this embodiment;

[0040] Take calcium carbonate, calcium hydroxide and add up to 15g, place 1L pure water, stir solution, then add konjac gum, guar gum, agar, sodium alginate and add up to 10g, ultrasonic stirring disperses, obtains homogeneous mixed solution, as induction phase;

[0041] Weigh 25g of calcium lactate and dissolve it in 1L of purified water as a solidification solution for later use.

[0042] Raise the temperature of the induction phase and solidification base phase configured above to 65°C, spray the induction phase onto the surface of the solidification base phase after atomization, and let it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com