Scraping ink as well as preparation method and application thereof

A technology of ink and color paste, applied in the field of scraping ink and its preparation, can solve the problems of pollution in the printing process, narrow application range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

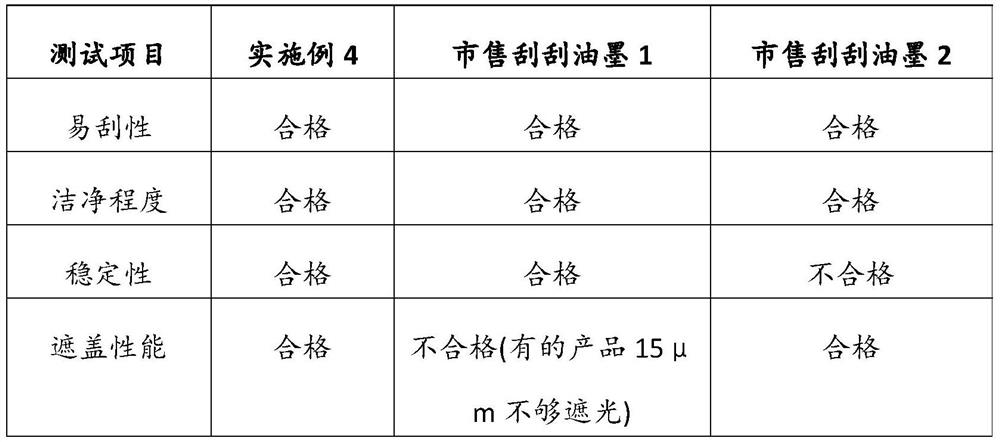

Examples

Embodiment 1

[0053] This embodiment prepares a kind of scraping ink, and this scraping ink comprises the following components by weight:

[0054] Color paste: 80 parts,

[0055] Water-based resin: 50 parts,

[0056] Leveling agent: 0.05 parts,

[0057] Defoamer: 0.05 parts.

[0058] Wherein, the water-based resin is water-based acrylate or water-based polyurethane.

[0059] The leveling agent is acrylate or modified polydimethylsiloxane.

[0060] Antifoaming agents include silica-containing mineral oil type antifoaming agents.

[0061] The scraping ink also contains an appropriate amount of pH adjuster ammonia water, which adjusts the pH to a pH value of 7-8, so that the resin can be stably dispersed in the solution.

[0062] The preparation method of the scratch-off ink is as follows: in a stirring state, add water-based resin, leveling agent, defoamer and pH regulator into the color paste in sequence, and disperse evenly. The stirring speed is 500rpm, and the time is 45min.

[006...

Embodiment 2

[0070] This embodiment prepares a kind of scraping ink, and this scraping ink comprises the following components by weight:

[0071] Color paste: 100 parts,

[0072] Water-based resin: 75 parts,

[0073] Leveling agent: 1 part,

[0074] Defoamer: 1 part.

[0075] Wherein, the water-based resin is water-based acrylate or water-based polyurethane.

[0076] The leveling agent is acrylate or modified polydimethylsiloxane.

[0077] Antifoaming agents include silica-containing mineral oil type antifoaming agents.

[0078] The scraping ink also contains an appropriate amount of pH adjuster ammonia water, which adjusts the pH to a pH value of 7-8, so that the resin can be stably dispersed in the solution.

[0079] The preparation method of the scratch-off ink is as follows: in a stirring state, add water-based resin, leveling agent, defoamer and pH regulator into the color paste in sequence, and disperse evenly. The stirring speed is 500rpm, and the time is 45min.

[0080] Wherei...

Embodiment 3

[0087] This embodiment prepares a kind of scraping ink, and this scraping ink comprises the following components by weight:

[0088] Color paste: 120 parts,

[0089] Water-based resin: 100 parts,

[0090] Leveling agent: 2 parts,

[0091] Defoamer: 2 parts.

[0092] Wherein, the water-based resin is water-based acrylate or water-based polyurethane.

[0093] The leveling agent is acrylate or modified polydimethylsiloxane.

[0094] Antifoaming agents include silica-containing mineral oil type antifoaming agents.

[0095] The scraping ink also contains an appropriate amount of pH adjuster ammonia water, which adjusts the pH to a pH value of 7-8, so that the resin can be stably dispersed in the solution.

[0096] The preparation method of the scratch-off ink is as follows: in a stirring state, add water-based resin, leveling agent, defoamer and pH regulator into the color paste in sequence, and disperse evenly. The stirring speed is 500rpm, and the time is 45min.

[0097] W...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com