Modified decorative concrete material and preparation method thereof

A decorative concrete and modified technology, applied in the field of artificial stone, can solve the problems of lack of anti-fouling performance and self-cleaning performance, achieve superior physical and mechanical properties, superior weather resistance and corrosion resistance, and improve the effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

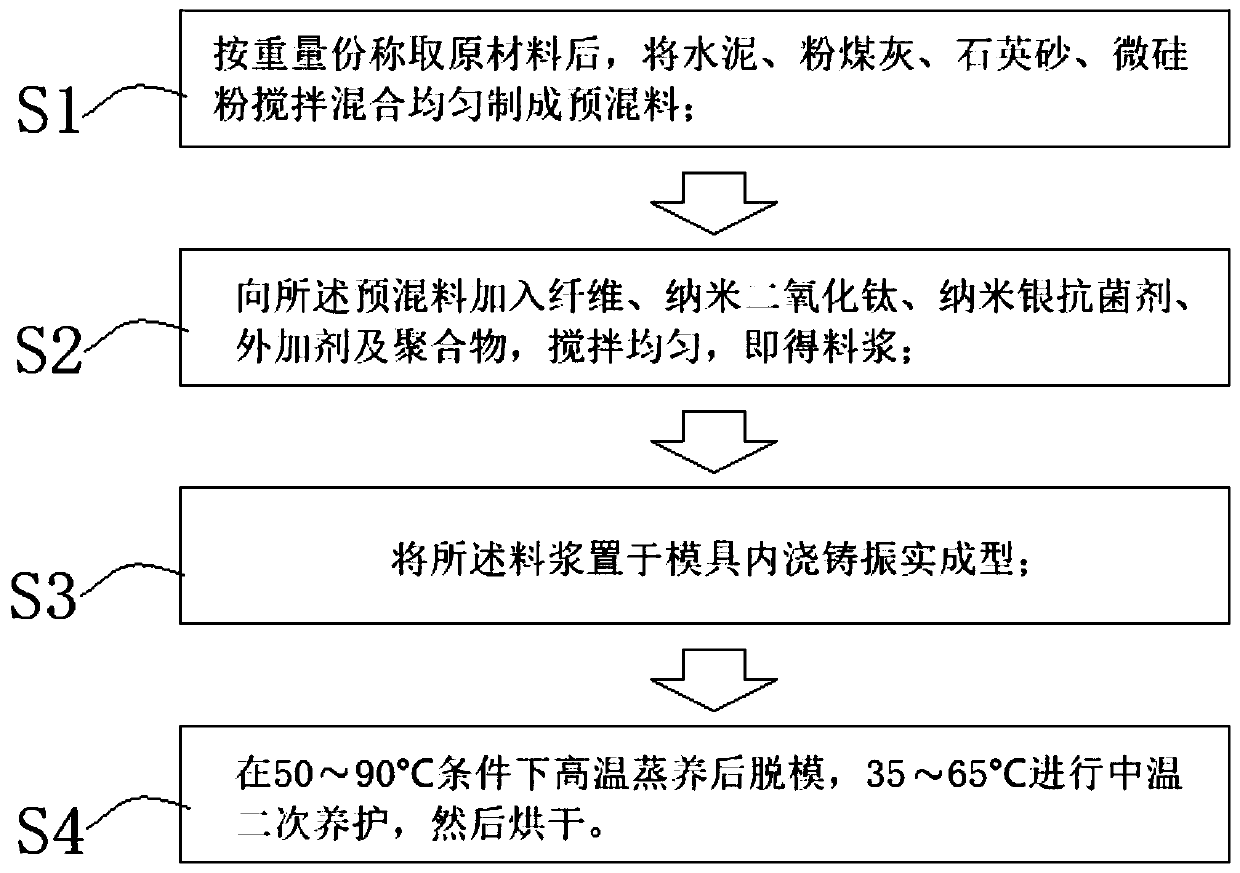

[0091] refer to figure 1 Shown, the present invention also proposes a kind of preparation method of modified decorative concrete material, comprises the following steps:

[0092] S1 After weighing the raw materials in parts by weight, mix cement, fly ash, quartz sand, and silica fume evenly to make a premix;

[0093] S2 Add fiber, modified nano-titanium dioxide, modified nano-silver antibacterial agent, admixture and polymer to the premix, stir evenly to obtain slurry;

[0094] S3 placing the slurry in a mold, casting and vibrating, and drying naturally to obtain a decorative concrete material;

[0095] S4 is demolded after high-temperature steam curing at 50-90°C, followed by medium-temperature secondary curing at 35-65°C, and then dried.

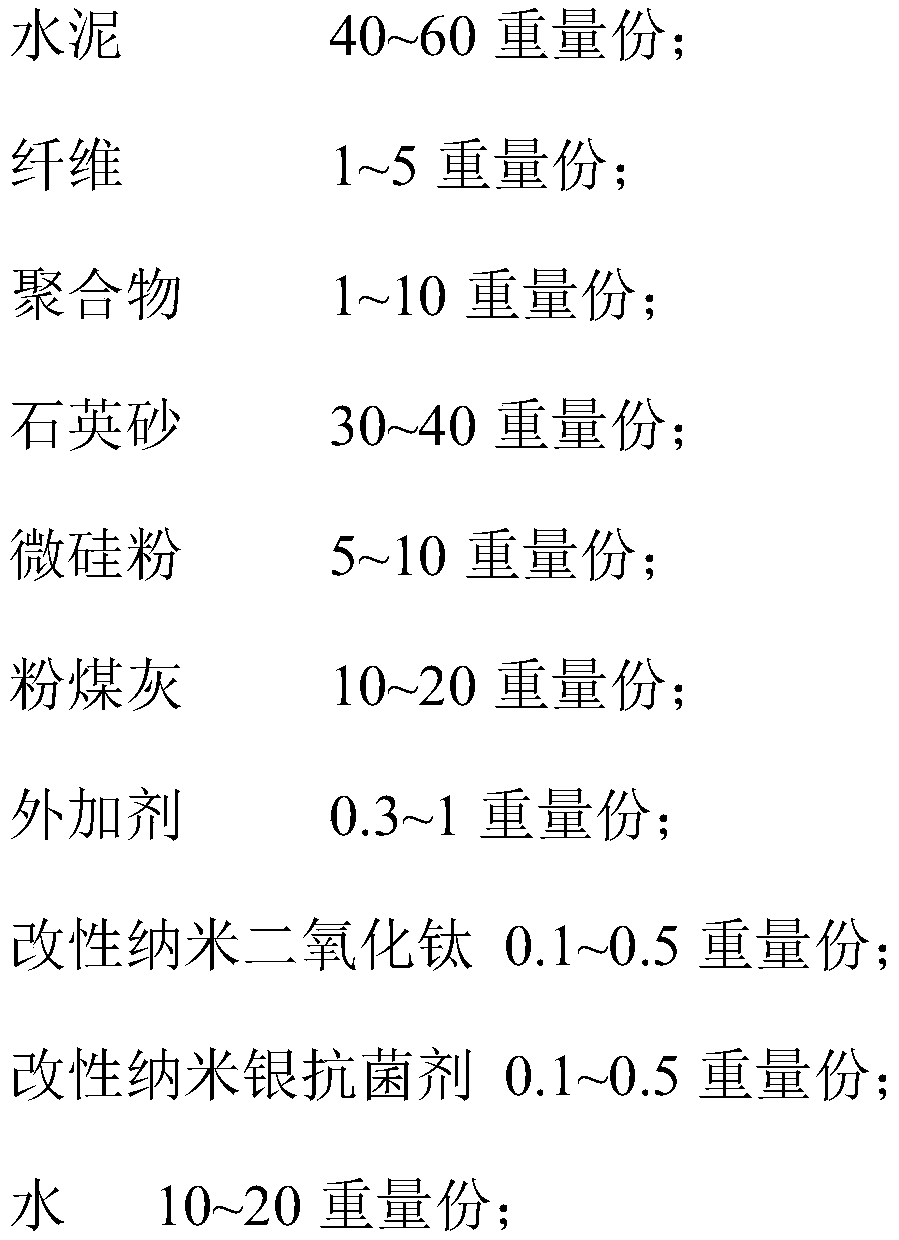

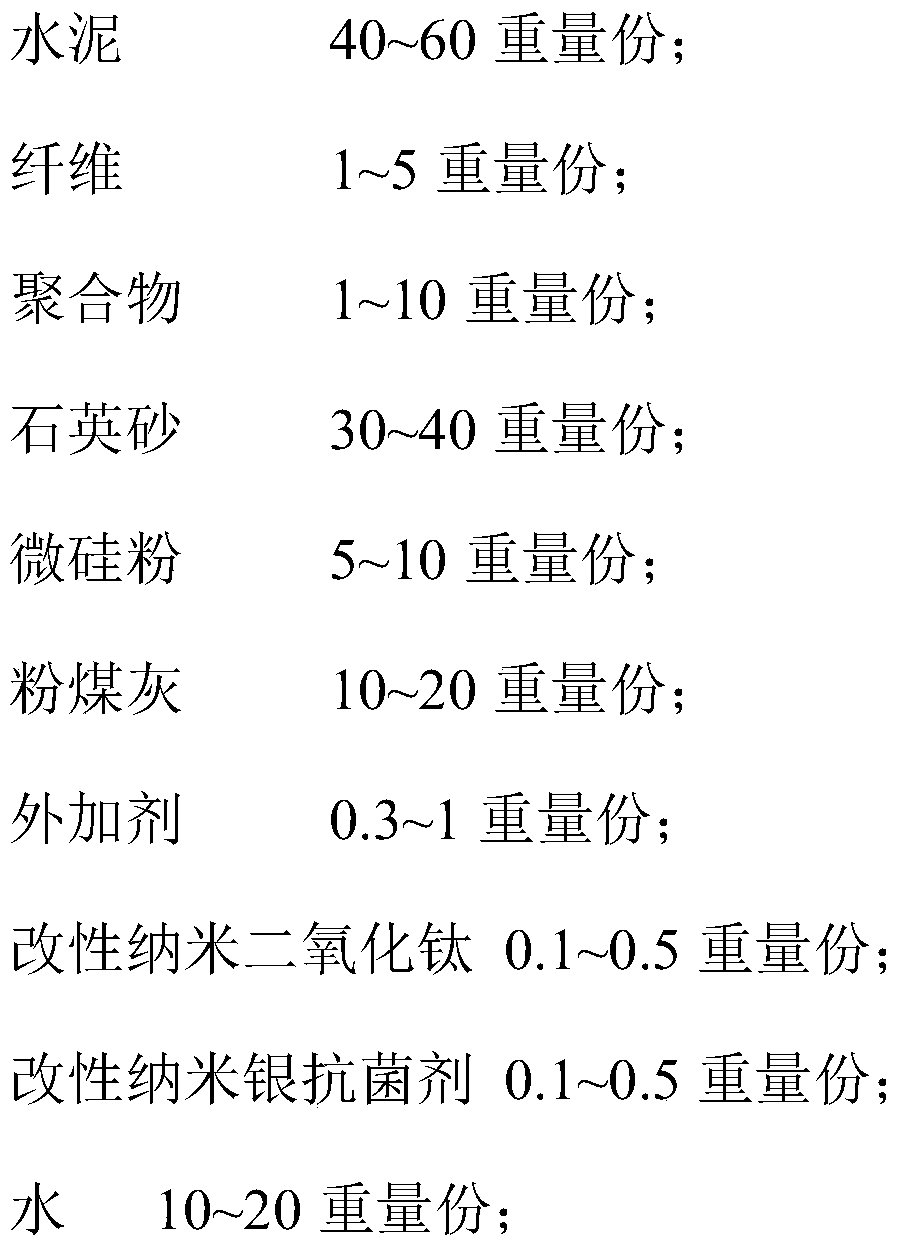

[0096] In the above content of the present invention, the raw material includes the following components by weight:

[0097]

[0098] Wherein, the admixture includes at least one of pigments, water reducers, thickeners, retarders, ea...

Embodiment 1

[0101] A modified decorative concrete material, comprising the following components in parts by weight:

[0102]

[0103] The modified nano titanium dioxide is prepared by a sol-gel method, wherein the iron doping amount in the modified nano titanium dioxide is 0.5%, and the iodine doping amount is 10%.

[0104] Described modified nano-silver antibacterial agent is made by following method:

[0105] Step 1. Add 50g of polyvinylpyrrolidone and 375mL of ethylene glycol into the reaction vessel, stir and dissolve at 85°C, then add 2g of silver nitrate, and stir at 120°C in the dark to prepare a nano-silver colloidal solution;

[0106] Step 2: Add 50mL toluene, 2.5mL tetraethyl orthosilicate, 1mL triethylamine, 1mL γ methacryloxypropyl trimethoxysilane to the nano-silver colloidal solution, react at room temperature for 18h, wash with absolute ethanol Wash, centrifuge, and dry at 60°C to obtain the modified nano-silver antibacterial agent.

[0107] The preparation process of ...

Embodiment 2

[0113] A modified decorative concrete material, comprising the following components in parts by weight:

[0114]

[0115]

[0116] The modified nano titanium dioxide is prepared by a sol-gel method, wherein the iron doping amount in the modified nano titanium dioxide is 0.5%, and the iodine doping amount is 5%.

[0117] Described modified nano-silver antibacterial agent is made by following method:

[0118] Step 1. Add 50g of polyvinylpyrrolidone and 375mL of ethylene glycol into the reaction vessel, stir and dissolve at 85°C, then add 2g of silver nitrate, and stir at 120°C in the dark to prepare a nano-silver colloidal solution;

[0119] Step 2: Add 50mL toluene, 2.5mL tetraethyl orthosilicate, 1.5mL triethylamine, 1mL γ methacryloxypropyl trimethoxysilane to the nano-silver colloidal solution, react at room temperature for 18h, and use anhydrous Wash with ethanol, centrifuge, and dry at 60°C to obtain the modified nano-silver antibacterial agent.

[0120] The prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com