A kind of light artificial culture stone and preparation method thereof

A cultural stone and artificial technology, applied in the field of materials, can solve the problems of high density, cumbersome processing procedures, poor workability of ceramsite concrete, etc., achieve strong durability and color stability, reasonable preparation method and process, improve thermal insulation and heat insulation. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

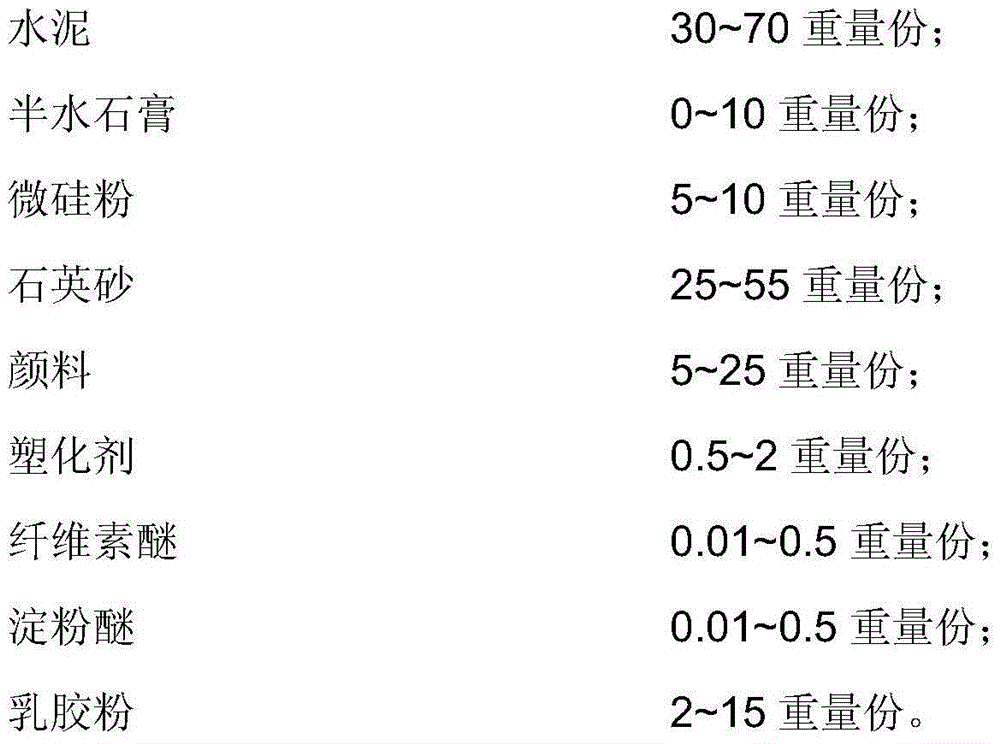

[0065] The preparation method of a kind of above-mentioned light-weight artificial culture stone of the embodiment of the present invention comprises:

[0066] 1) Prepare the mold; 2) Prepare the color layer and slurry layer of the surface layer of the light artificial culture stone as described above; 2.1) Prepare an aqueous solution of foaming agent, and foam it into microfoam; 2.2) Introduce microfoam into Add cement, ceramsite and other components of the bottom layer, and mix and stir to make a fluid bottom layer slurry; 3) Spray the prepared surface layer slurry on the inner surface of the mold to form a surface layer; 4) In the The bottom layer slurry prepared by pouring in the mold, vibrating molding; 5) Steam curing the vibration molded product at 40~70 ℃; 6) Demoulding the steam curing product, after demoulding, the temperature is not lower than 5 ℃ Condition for secondary maintenance.

[0067] The light-weight artificial cultural stone of the invention has excellent...

Embodiment 1

[0079] 1) Preparing the mold: according to the needs of the market and customers, use the natural or pre-processed stone model to remake the mold;

[0080] 2) Prepare the slurry of the color layer and the pulp layer in the surface layer, wherein the components of the pulp layer pulp include:

[0081] 45 parts by weight of white Portland cement;

[0082] 8 parts by weight of white aluminate cement;

[0083] 6 parts by weight of microsilica;

[0084] 30 parts by weight of quartz sand;

[0085] 8 parts by weight of pigment;

[0086] 0.6 parts by weight of high-performance polycarboxylate superplasticizer;

[0087] Cellulose ether 0.02 parts by weight;

[0088] Starch ether 0.01 parts by weight;

[0089] 3 parts by weight of acrylic redispersible latex powder;

[0090] 2.1) According to the weight ratio of the total weight of animal protein foaming agent and triethanolamine to water is 1:20, prepare an aqueous solution of foaming agent, and foam it into micro-foam in a foam...

Embodiment 2

[0107] 1) Preparing the mold: according to the needs of the market and customers, use the natural or pre-processed stone model to remake the mold;

[0108] 2) Prepare the slurry of the color layer and the pulp layer in the surface layer, wherein the components of the pulp layer pulp include:

[0109] 50 parts by weight of white Portland cement;

[0110] 4 parts by weight of hemihydrate gypsum;

[0111] 5 parts by weight of microsilica;

[0112] 35 parts by weight of quartz sand;

[0113] 4 parts by weight of pigment;

[0114] 0.7 parts by weight of high-performance polycarboxylate superplasticizer;

[0115] Cellulose ether 0.02 parts by weight;

[0116] Starch ether 0.02 parts by weight;

[0117] 2 parts by weight of acrylic redispersible latex powder;

[0118] 2.1) According to the weight ratio of the total weight of vegetable foaming agent and triethanolamine to water is 1:20, prepare an aqueous solution of foaming agent, and foam it into micro-foam in a foaming machi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com