Methyl methacrylate (MMA) floor coating capable of rapidly solidifying

A floor coating, fast curing technology, applied in the direction of coating, can solve the problems of long curing time, limited application, easy cracking, etc., to achieve the effect of good anti-slip effect, wide application and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0035] 1. Preparation of MMA resin prepolymer

[0036] The methyl methacrylate of 20g, the butyl acrylate of 10g, the acrylic acid of 4g and the benzoyl peroxide of 0.04g are joined in the four-necked flask that thermometer, condenser, stirrer are equipped with, water bath heating, temperature is controlled at 85°C, heat preservation reaction for 2 hours to make MMA resin prepolymer, set aside.

[0037] 2. Preparation of MMA floor coating

[0038] The prepolymer of 28g is poured in the beaker, after diluting with the methyl methacrylate of 12g and butyl acrylate of 12g, add talcum powder 13g, plasticizer 8g, defoamer 4g, wax liquid 4g, initiator 8g, 4g of curing accelerator, fully stirred for 5 minutes to obtain a coating. In the absence of air bubbles, the paint was injected into the previously prepared mold and allowed to cure to a 2 mm thick coating within 1 hour at room temperature.

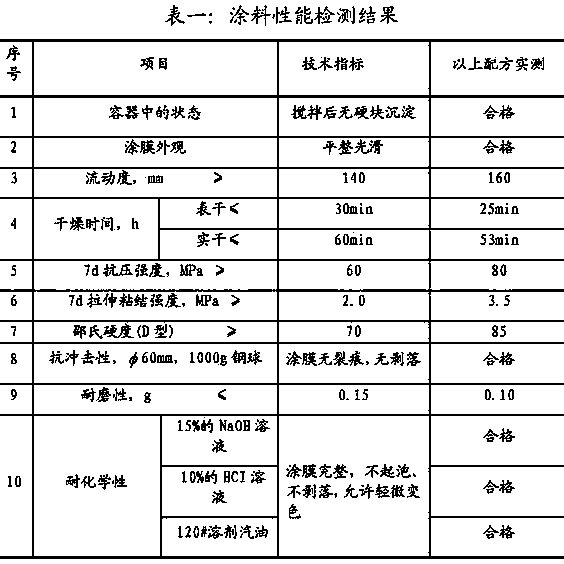

[0039] The MMA floor coating prepared by example 1 and the MMA floor coating perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com