Precise ceramic 3D printer and printing method based on same

A 3D printer and ceramic technology, applied in the field of precision ceramic 3D printers and their printing, can solve the problems of ordinary daily ceramics being unable to bear the cost, high cost, printing failure, etc., to improve the design and production molding time, improve the diversity and creativity, improving the effect of molding aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

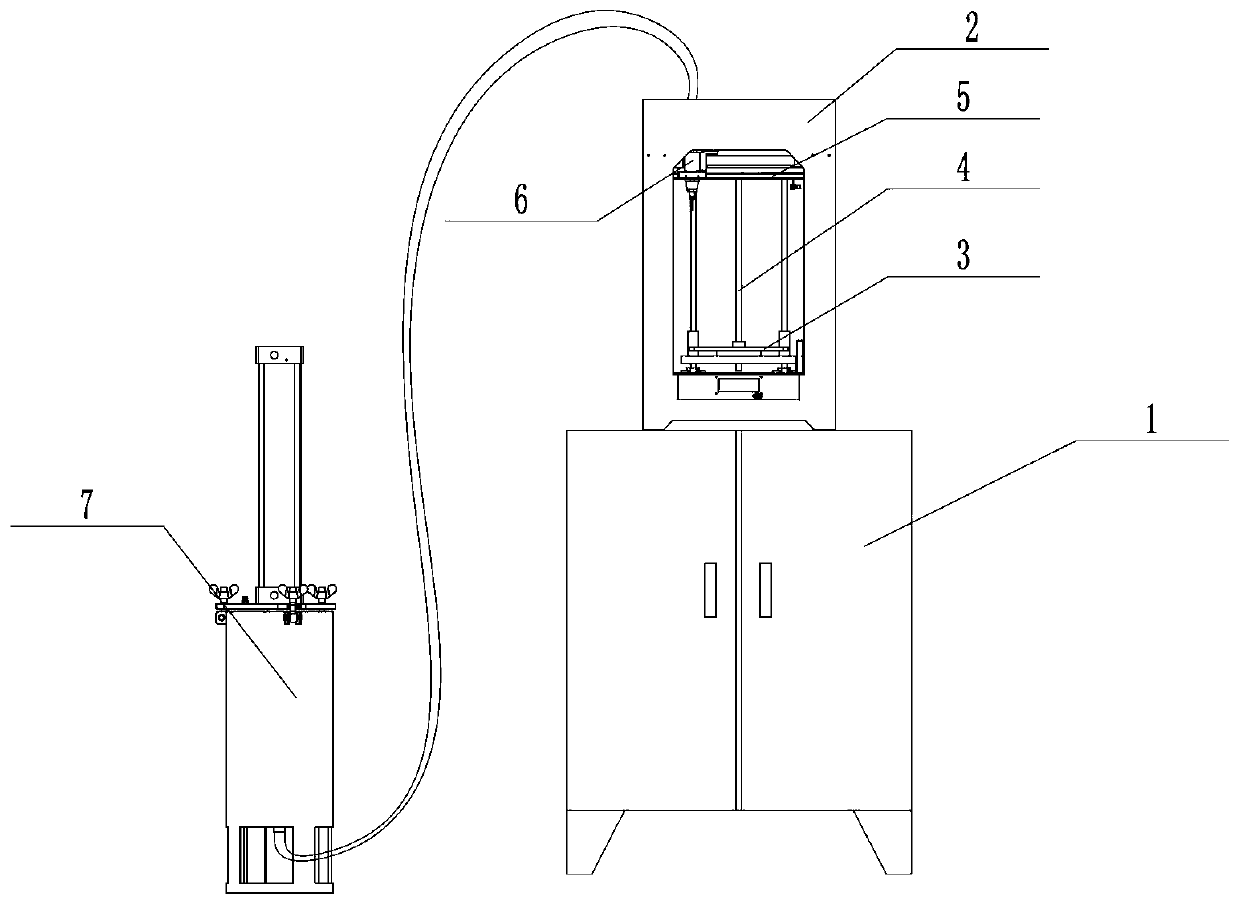

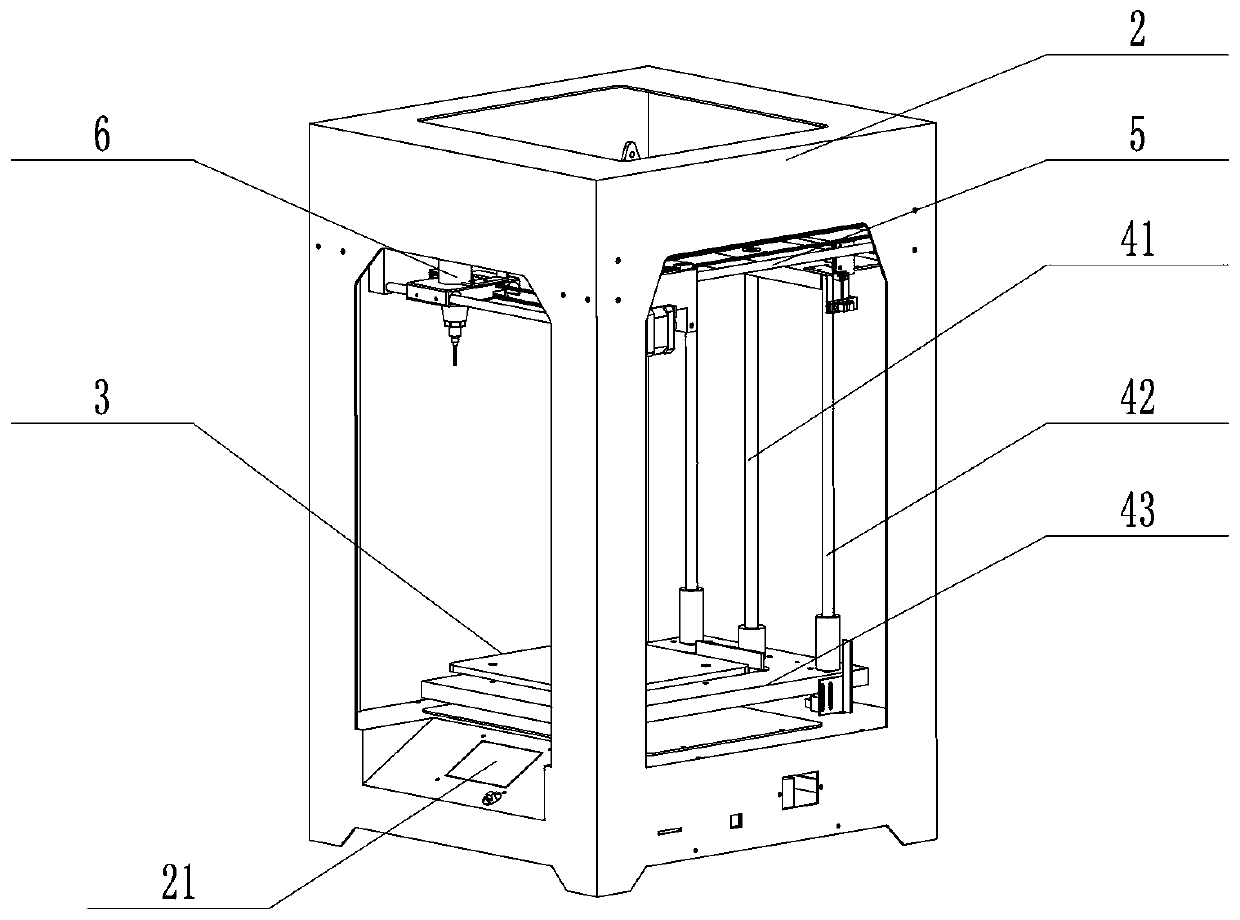

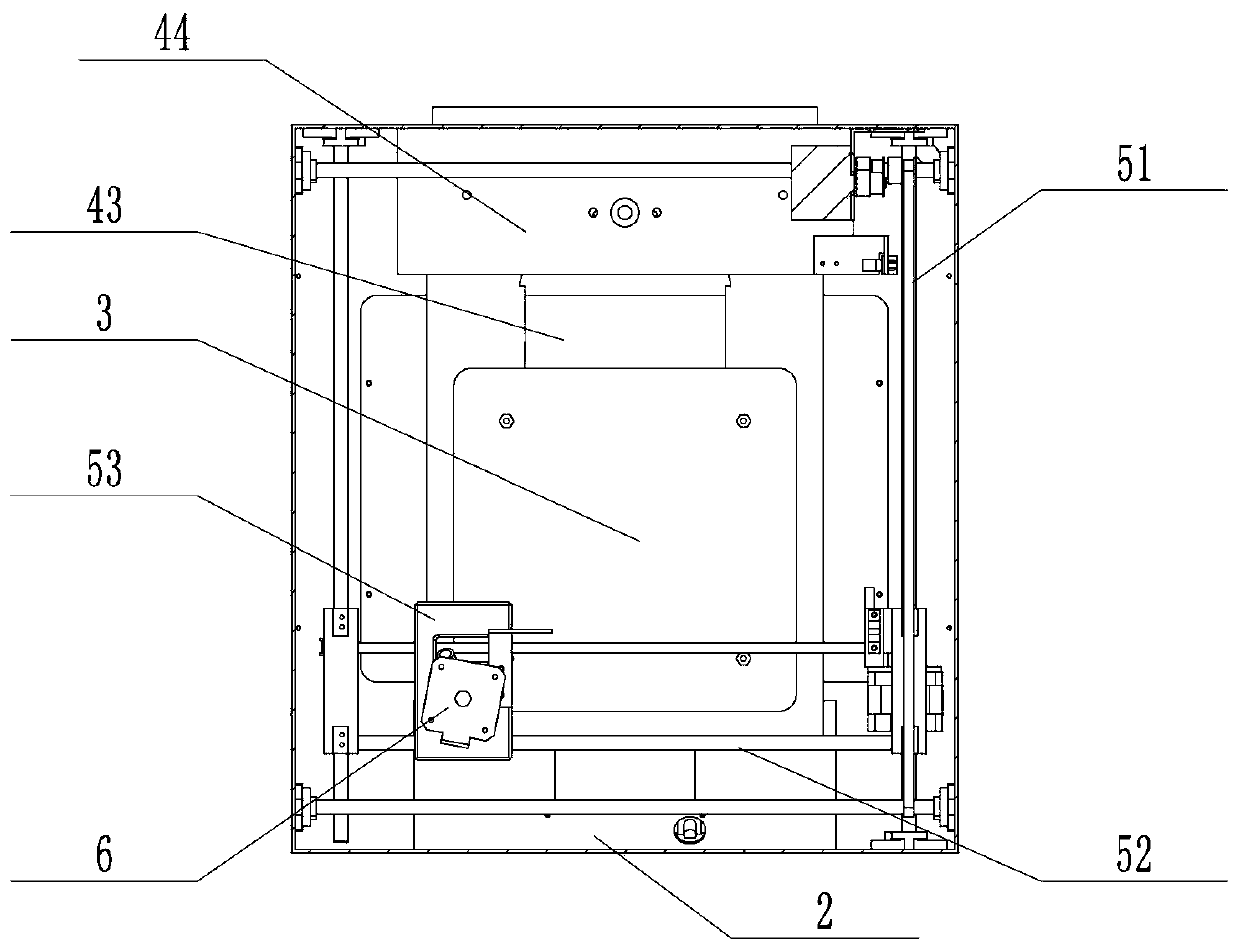

[0036] A kind of precision ceramic 3D printer of the embodiment of the present invention such as Figure 1-6 As shown, it includes a bracket, a printing frame, a printing base plate, a lifting frame, a printing head, a moving device and a feeding barrel, the printing frame is placed on the support, and the lifting frame is fixed on the bottom of the printing frame. The printing bottom plate is fixed on the lifting frame, the moving device is fixed on the top of the printing frame, the printing head is installed on the moving device, the feeding barrel is connected with the printing head pipe, the The print head includes a mounting plate, an extrusion motor, a conveying screw and a working head, the extrusion motor is fixed on the upper surface of the mounting plate, the working head is fixed at the center of the lower surface of the mounting plate, and the working The center of the head is provided with a working groove that runs through the working head and matches the convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com