Intermediate temperature crackled glaze porcelain for daily use and preparation method thereof

A technology of cracked glaze and daily-use porcelain, which is applied in the field of medium-temperature cracked-glazed daily-use porcelain and its preparation, can solve the problems of product quality, food safety hazards, food safety hazards, and high production costs, so as to shorten preparation time, improve quality, and resist The effect of improving the folding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

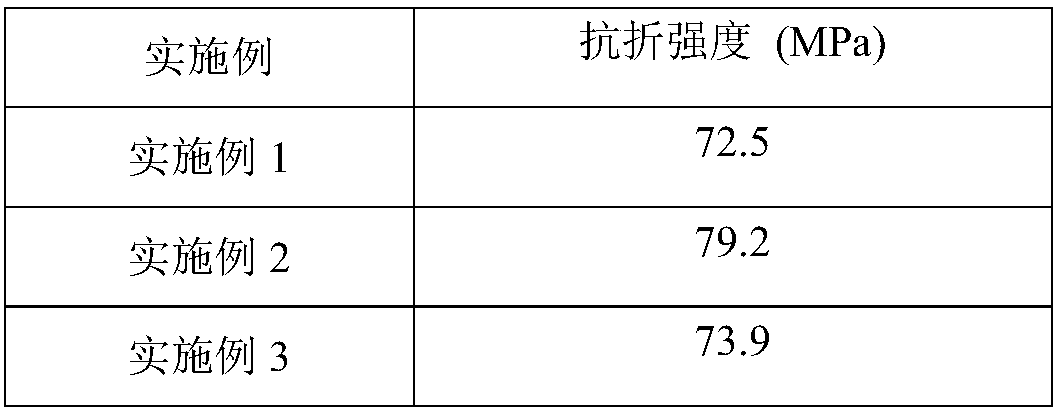

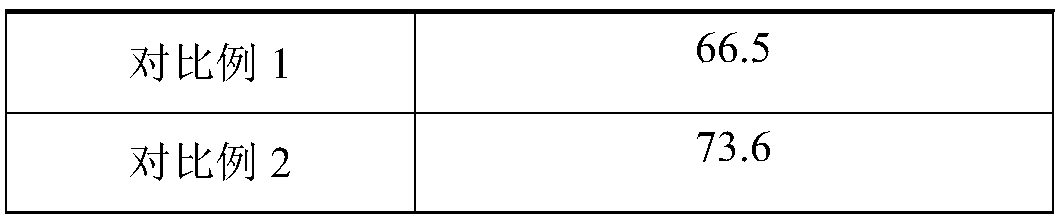

Examples

Embodiment 1

[0037] A medium-temperature cracked glaze daily-use porcelain, including a blank and a glaze, and the blank includes the following components and their parts by weight: 10 parts of Jiangxi Pingxiang washed quartz powder, 33 parts of Hengshan albite, 20 parts of Shaoguan washed kaolin, and 33 parts of Fujian washed kaolin parts, Henan Nanyang porcelain clay 7 parts, dolomite mineralizer 0.7 parts.

[0038] The preparation method of medium-temperature cracked glaze daily-use porcelain: 1) prepare materials according to each component and the weight of each component, put the raw materials into a ball mill, add an appropriate amount of water, and wet ball mill together for 12 hours to obtain a fineness of 250 mesh sieve 0.05-0.15% base slurry, sieving, iron removal, mud pressing, mud refining, sinking, and then roll forming to obtain a wet billet, drying, and trimming to obtain a green billet; the mass ratio of raw materials, ball stones, and water is 1:1.7:1.3;

[0039] 2) The ...

Embodiment 2

[0041] A medium-temperature cracked glaze daily-use porcelain, including a blank and a glaze. The blank includes the following components and their parts by weight: 12 parts of Jiangxi Pingxiang washed quartz powder, 28 parts of Hengshan albite, 27 parts of Shaoguan washed kaolin, and 28 parts of Fujian washed kaolin 1 part, 5 parts of Henan Nanyang porcelain clay, 1 part of dolomite mineralizer.

[0042] The preparation method of medium-temperature cracked glaze daily-use porcelain: 1) prepare materials according to each component and the weight of each component, put the raw materials into a ball mill, add an appropriate amount of water, and wet ball mill together for 12 hours to obtain a fineness of 250 mesh sieve 0.05-0.15% base slurry, sieving, iron removal, mud pressing, mud refining, sinking, and then roll forming to obtain a wet billet, drying, and trimming to obtain a green billet; the mass ratio of raw materials, ball stones, and water is 1:1.5:1.2;

[0043] 2) The ...

Embodiment 3

[0045] A medium-temperature cracked glaze daily-use porcelain, including a blank and a glaze. The blank includes the following components and their parts by weight: 15 parts of Jiangxi Pingxiang washed quartz powder, 29 parts of Hengshan albite, 25 parts of Shaoguan washed kaolin, and 25 parts of Fujian washed kaolin parts, Henan Nanyang porcelain clay 10 parts, dolomite mineralizer 0.5 parts.

[0046] The preparation method of medium-temperature cracked glaze daily-use porcelain: 1) prepare materials according to each component and the weight of each component, put the raw materials into a ball mill, add an appropriate amount of water, and wet ball mill together for 12 hours to obtain a fineness of 250 mesh sieve 0.05-0.15% base slurry, sieving, iron removal, mud pressing, mud refining, sinking, and then roll forming to obtain a wet billet, drying, and trimming to obtain a green billet; the mass ratio of raw materials, ball stones, and water is 1:1.4:1.3;

[0047] 2) The gre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com