Crystalline glaze of iron, zinc and augite and its material compounding process

A technology of crystalline glaze and pyroxene, which is applied in the field of ceramic glaze preparation, and can solve the problems that crystalline glaze cannot be directly used for daily ceramic tableware.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

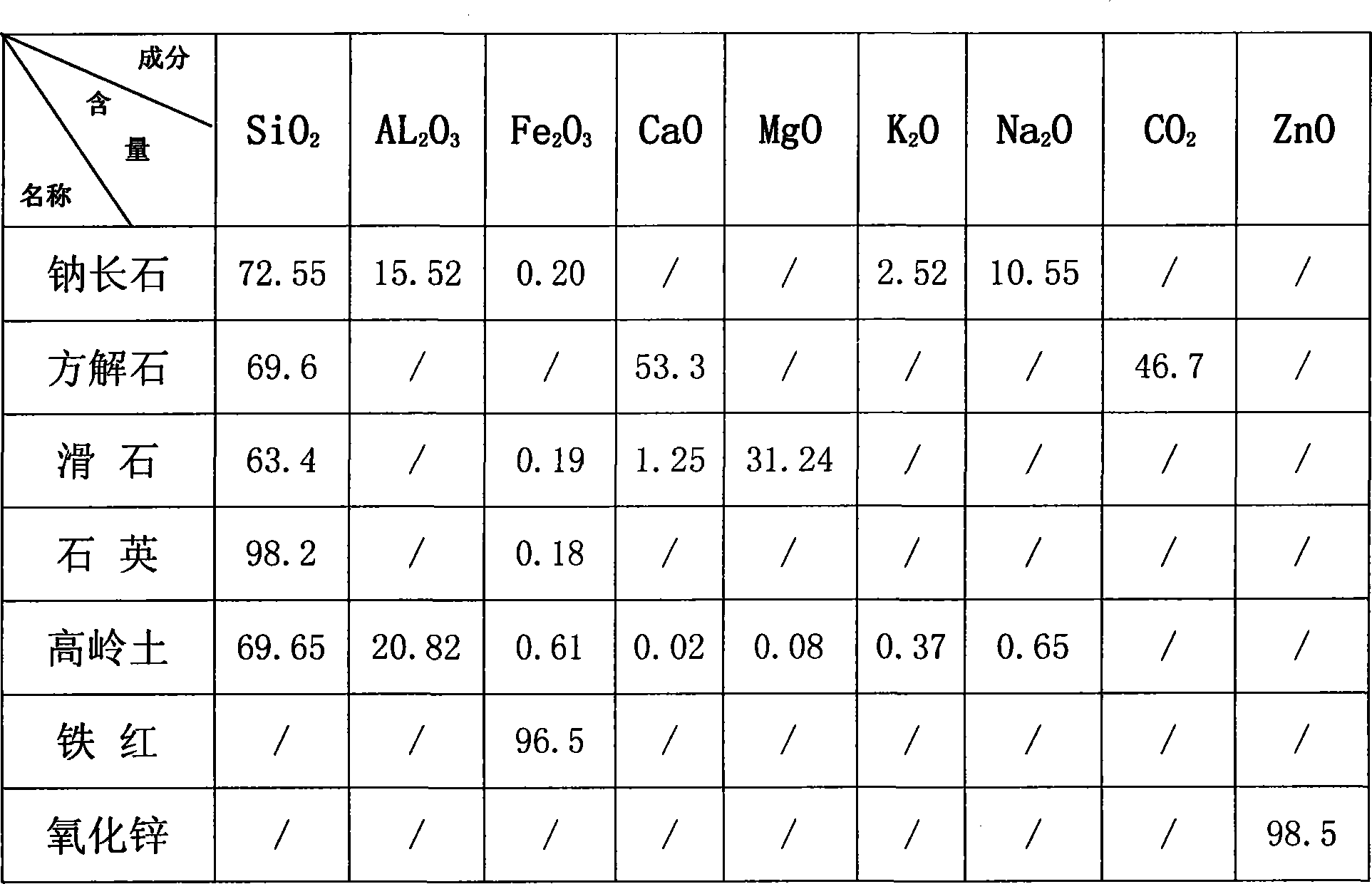

[0024] Take the following materials and carry out proportioning according to parts by weight:

[0025] Albite 25 parts Calcite 10 parts Talc 20 parts Zinc oxide 5 parts

[0026] 20 parts of quartz, 5 parts of kaolin, 15 parts of iron red

[0027] The above-mentioned ingredients are mixed and ball milled for 48 hours (material: ball: water=1: 1.8: 0.8) and the resulting slurry after passing through a 250 mesh sieve is the glaze of the present invention, and then the glaze is applied to the green body, (the thickness of the glaze layer is 0.3 -0.5mm), after drying, it is fired in a roller kiln at a temperature of 1280°C, and the firing cycle is 8 hours. It will produce a black base color, a yellow-green crystal product, and the crystals in the glaze are evenly distributed, and the effect is very good.

example 2

[0029] Take the following materials and carry out proportioning according to parts by weight:

[0030] Albite 20 parts Calcite 18 parts Talc 15 parts Zinc oxide 3 parts

[0031] Quartz 25 parts Kaolin 3 parts Iron Red 5 parts

Embodiment 2

[0032] The manufacturing process of the second embodiment is the same as that of the first embodiment. Mix the above ingredients and ball mill for 48 hours (material: ball: water = 1: 1.8: 0.8) and pass through a 250 mesh sieve to obtain the slurry of the present invention, which is applied to the green body, (the thickness of the glaze layer is 0.3- 0.5mm), after drying, it is fired in a roller kiln at a firing temperature of 1280°C and a firing cycle of 8 hours. It will produce a black base color and a yellow-green crystal product. The crystals in the glaze are evenly distributed, and the effect is very good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com